Chamfered crystallizer with taper continuous casting plate blank

A chamfering crystallizer and crystallizer technology, applied in the field of steelmaking-continuous casting, can solve the problems of chamfering continuous casting slab corner longitudinal cracks, not considering the taper of the chamfering surface, difficult to maintain and clean, etc., to achieve higher temperature , eliminate corner defects, and facilitate maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

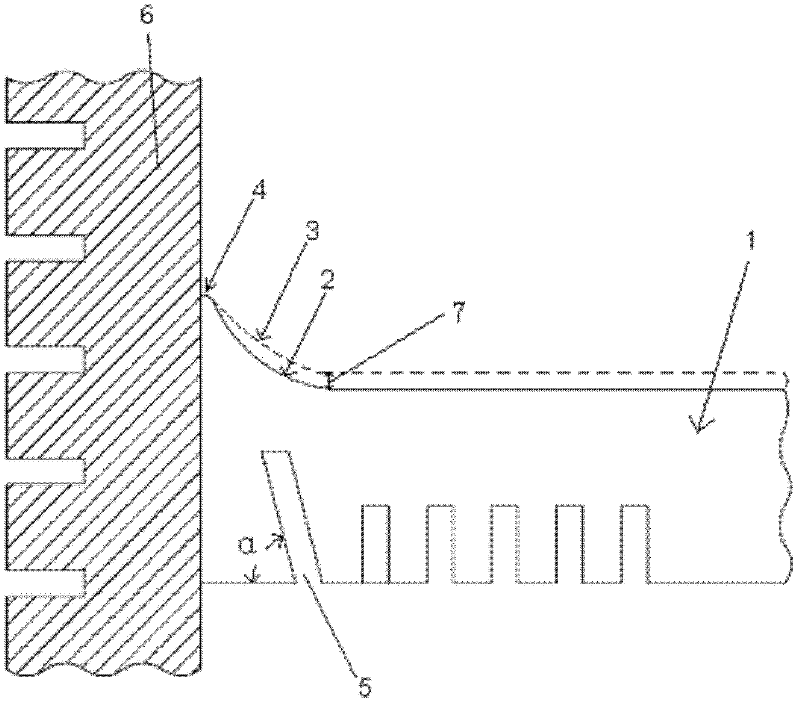

Embodiment 1

[0031]A steel factory adopts the chamfering crystallizer with taper of the present invention when casting 220mm×2000mm continuous casting slabs on a continuous casting machine. The width of the end platform is 3mm, the arc radius of the upper mouth of the crystallizer on the chamfered surface is 120mm, the arc radius of the lower mouth of the crystallizer is 105mm, and the chamfering radius at the junction of the transition surface and the narrow surface and the platform is 2mm. The taper value of the chamfered surface in the direction of the narrow copper plate at the junction of the surface copper plate is 1.0mm. The cooling water gap at the chamfer is at an angle of 80° with the horizontal plane, the length of the water gap is 30mm, and the width of the water gap is 6mm. The cooling water volume of the copper plate on the wide surface of the mold is 4000L / min, and the cooling water volume on one side of the copper plate on the narrow surface of the crystallizer is 250L / min. ...

Embodiment 2

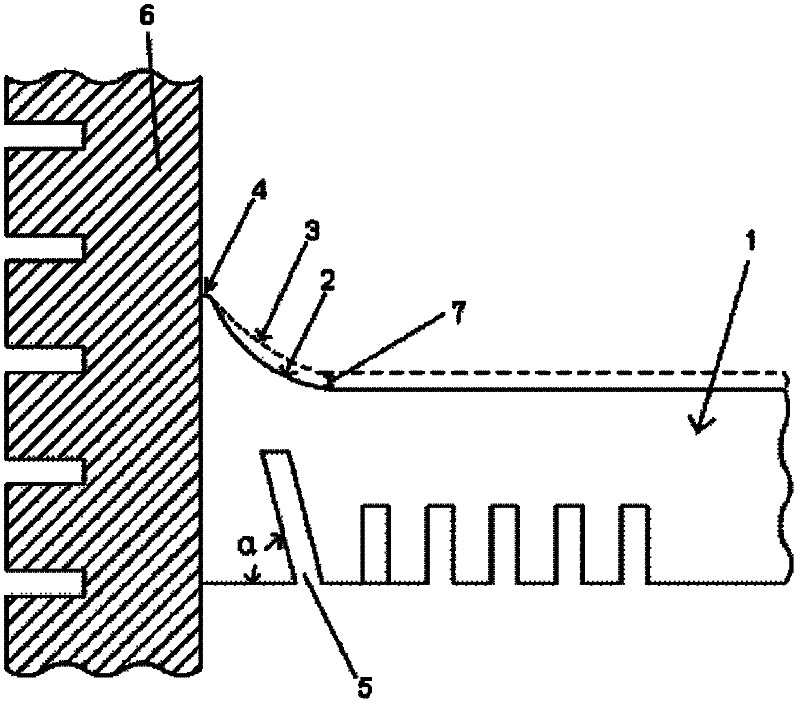

[0033] A steel factory adopts the chamfering crystallizer with its own taper of the present invention when casting 250mm×1800mm continuous casting slabs on a continuous casting machine. The width of the end platform is 1mm, the arc radius of the upper mouth of the crystallizer on the chamfered surface is 80mm, the arc radius of the lower mouth of the crystallizer is 65mm, and the chamfering radius at the junction of the transition surface and the narrow surface and the platform is 6mm. The taper value of the chamfered surface in the direction of the narrow copper plate at the junction of the surface copper plate is 1.5mm. The cooling water gap at the chamfering part forms an angle of 70° with the horizontal plane, the length of the water gap is 35mm, the width of the water gap is 5mm, the cooling water volume of the copper plate on the wide surface of the crystallizer is 5000L / min, and the cooling water volume on one side of the copper plate on the narrow surface of the crystal...

Embodiment 3

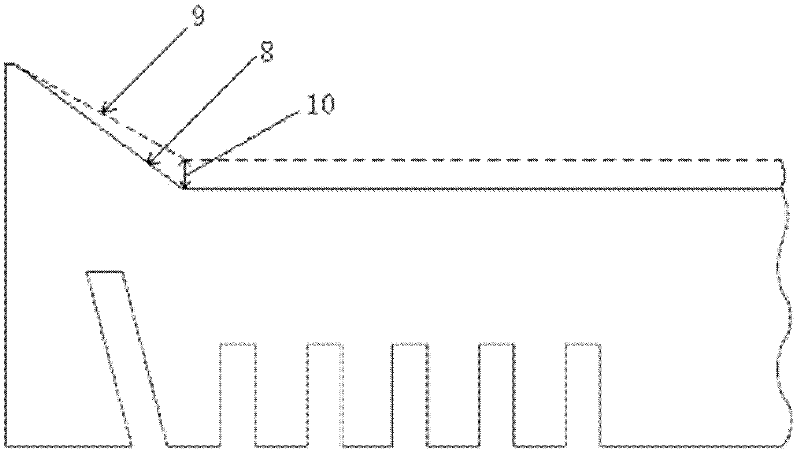

[0035] A steel factory adopts the self-contained taper chamfering crystallizer of the present invention when casting 320mm×2400mm continuous casting slabs on a continuous casting machine. The width of the platform is 2mm, the chamfered surface is flat, the length of the chamfered surface of the upper mouth of the crystallizer is 50mm, the length of the lower mouth of the crystallizer is 48mm, and the chamfering radius at the junction of the transitional surface and the narrow surface and the platform is 3mm. The taper of the chamfered surface from the junction of the wide copper plate to the narrow copper plate is 2 mm. The cooling water gap at the chamfer is at an angle of 65° with the horizontal plane, the length of the water gap is 40mm, the width of the water gap is 6mm, the cooling water volume of the copper plate on the wide surface of the mold is 6000L / min, and the cooling water volume on one side of the copper plate on the narrow surface of the mold is 500L / min , The t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com