Processing method of lactic acid fermented mustard powder flavoring

A lactic-acid-fermented mustard and lactic-acid-fermented technology, which is applied in the processing field of lactic-acid-fermented mustard powder seasoning, can solve the problems of reducing the flavor and quality of pickled cabbage stew, affecting flavor, taste, and changing taste, etc., and achieves easy operation and low cost of processing technology , Long shelf life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

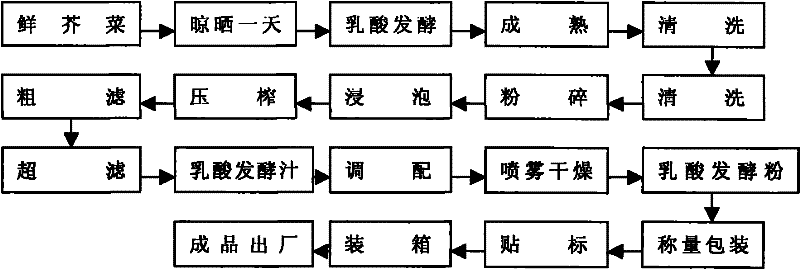

Image

Examples

Embodiment 1

[0019] 1. Take fresh pickled mustard in the sun for 1 day, and carry out lactic acid fermentation, with a salinity of 6%, to obtain mature mustard greens with bright yellow color, rich aroma and delicious taste;

[0020] 2. Cut lactic acid-fermented mature mustard into strips and blocks, and crush it with a grinder; then soak and press; then filter the squeezed filtrate through coarse filtration and then use membrane treatment technology to perform ultrafiltration to obtain clarified lactic-acid-fermented mustard juice;

[0021] 3. Add 8% β-dextrin and 1% monosodium glutamate in the lactic acid fermented mustard juice to make the mixture evenly;

[0022] 4. Adopt spray drying to process to obtain the lactic acid fermented mustard seasoning. The spray drying conditions are: inlet air temperature 249°C, outlet air temperature 98°C, feed rate 30ml / min, air compressor air pressure 0.18Mpa.

[0023] 5. Finally, the product can be weighed and packaged.

Embodiment 2

[0025] 1. Take fresh mustard greens in the sun for 1 day, and carry out lactic acid fermentation, requiring a salinity of 6%, to obtain mature mustard greens with bright yellow color, rich aroma and delicious taste;

[0026] 2. Cut the mature lactic acid fermented mustard into strips and blocks, and crush it with a pulverizer; then soak and squeeze; then, the squeezed filtrate is first coarsely filtered and then ultrafiltered by membrane treatment technology to obtain clarified lactic acid fermented mustard juice ;

[0027] 3. Add 7% β-dextrin, 1.2% monosodium glutamate and a small amount of ginger powder to the lactic acid fermented mustard juice to mix evenly;

[0028] 4. Adopt spray drying to process to obtain the lactic acid fermented mustard seasoning. The spray drying conditions are: inlet air temperature 249°C, outlet air temperature 98°C, feed rate 30ml / min, air compressor air pressure 0.18Mpa.

[0029] 5. Finally, the product can be weighed and packaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com