Rosin-modified phenol resin, manufacturing method thereof, and printing ink

A technology of rosin modification and phenolic resin, applied in the direction of ink, application, coating, etc., which can solve the problems of reducing gloss, ink smog scattering, and deterioration of working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0035] (Manufacture of alkylphenol-formaldehyde condensate)

[0036] Add 1,000 parts of octylphenol, 317 parts of 92% paraformaldehyde, 564 parts of xylene and 500 parts of water into a reaction vessel with a stirrer, a reflux cooling pipe with a water separator, and a thermometer, and heat up to 50°C under stirring . Next, 89 parts of 45% sodium hydroxide solution was added to the reaction vessel, and the temperature of the reaction system was slowly raised to 90° C. while cooling, and kept for 2 hours, and sulfuric acid was further added dropwise to adjust the pH value to about 6. Thereafter, the aqueous layer portion containing formaldehyde and the like was removed, and the content was cooled after washing with water again to prepare a 70% by weight xylene solution of soluble octylphenol (Octylphenol).

manufacture example 2

[0038] (Manufacture of alkylphenol-formaldehyde condensate)

[0039] Add 800 parts of octylphenol, 200 parts of butylphenol, 340 parts of 92% paraformaldehyde, 573 parts of xylene and 500 parts of water in the reaction vessel with stirrer, the reflux cooling pipe with water trap and thermometer. The temperature was raised to 50°C with stirring. Then, 89 parts of 45% sodium hydroxide solution were added to the reaction vessel, and the temperature of the reaction system was slowly raised to 90° C. while cooling, and kept for 2 hours, and sulfuric acid was further added dropwise to adjust the pH value to about 6. Thereafter, the aqueous layer portion containing formaldehyde and the like was removed, and the content was cooled after washing with water again to prepare a xylene solution having 70% by weight of soluble octyl / butylphenol.

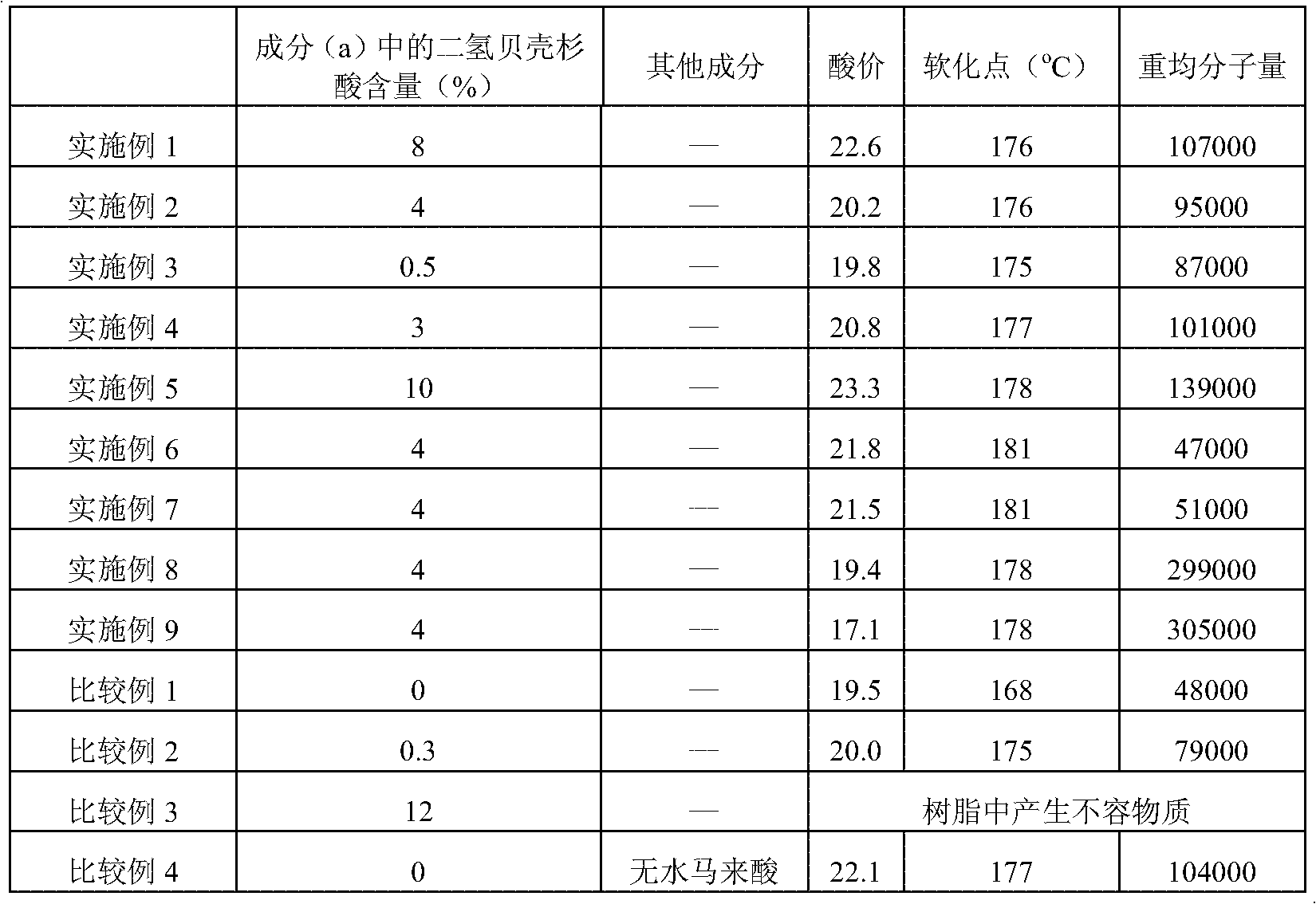

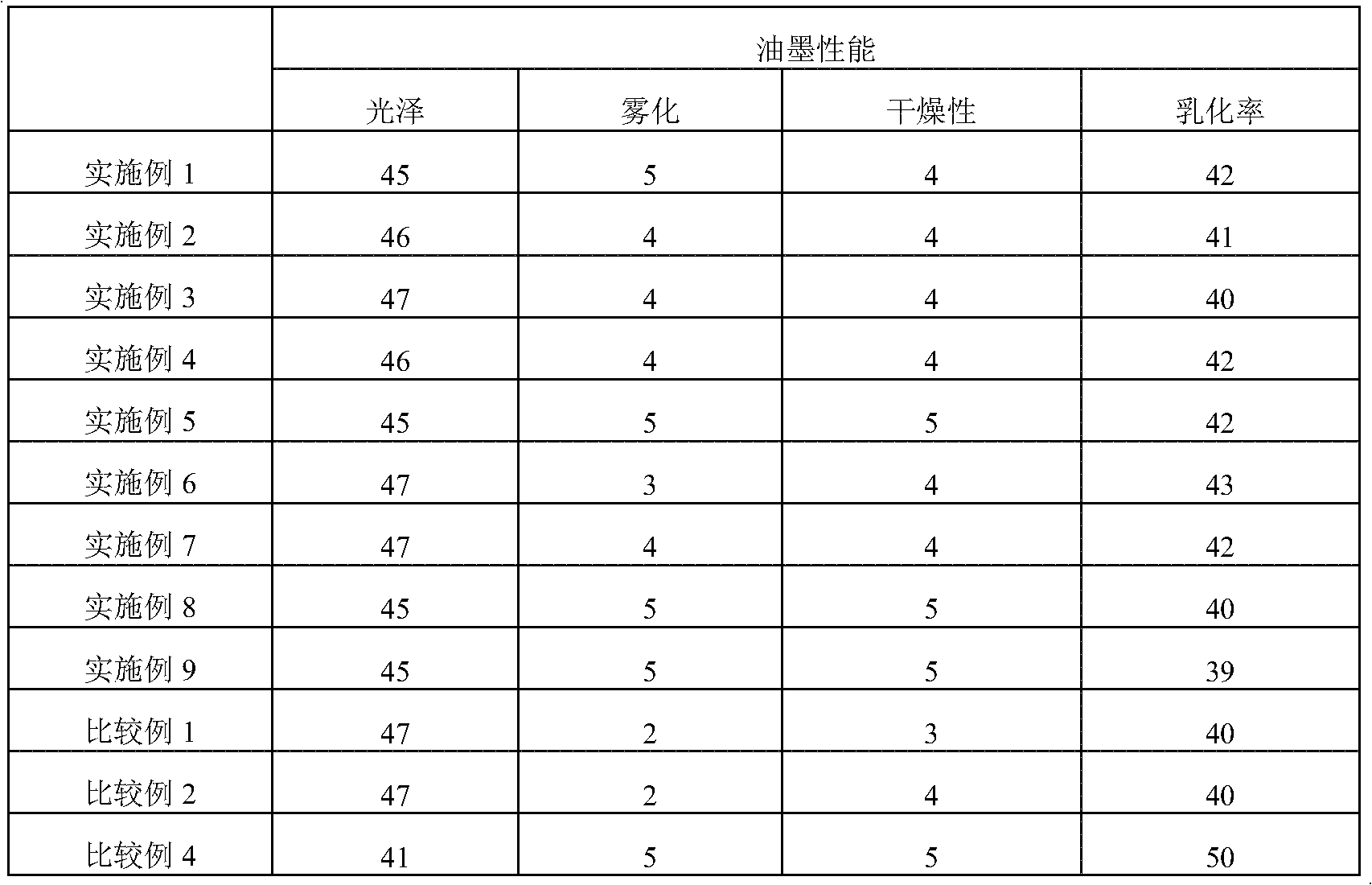

manufacture example A

[0042] In a reaction vessel equipped with a stirrer, a reflux cooling pipe with a water separator, and a thermometer, 1000 parts of Indonesian gum rosin (containing 8% of dihydrokauritic acid as component (a)) was added, and it was placed in a nitrogen atmosphere. While stirring, the temperature was raised to 180°C and melted. Next, 93 parts of pentaerythritol and 3 parts of magnesium hydroxide were added, and it heated up to 280 degreeC with stirring, and it reacted until the acid value became 25 mgKOH / g or less. After further cooling to 230°C, 714 parts (500 parts of solid) of xylene solution containing 70% by weight of soluble octylphenol of Production Example 1 was dropped into the reaction system at a temperature range of 230°C to 260°C over 9 hours. After completion of the dropping, the viscosity of the 33% by weight linseed oil was adjusted to 10 Pa·s, and the content was taken out after reducing the pressure at 0.02 MPa for 10 minutes. The acid value of the rosin-modi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com