Method for making copper cylinder on circuit board and circuit board with surface copper cylinders

A circuit board and copper column technology, which is applied in the direction of multi-layer circuit manufacturing, printed circuit components, electrical connection printed components, etc. Application and other problems, to achieve the effect of not easy to break and fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

other Embodiment approach

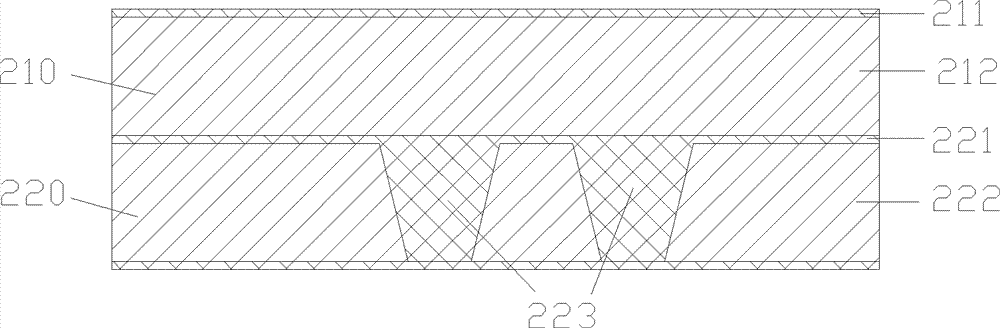

[0020] In other embodiments, when it is necessary to electrically connect the mounted flip chip with the circuit patterns of other layers within the second outer layer, the first blind hole 213 can be connected to the multi-layer when making the first blind hole 213. The second blind hole 223 in the sub-outer layer 220 of the substrate is a solid conductive blind hole filled and leveled by electroplating.

[0021] In this case, before making the first blind hole 213, at least one second blind hole 223 should be made in the second outer layer 220 according to the flip chip to be packaged, and the second blind hole 223 should be filled by electroplating. The blind hole 223 makes it a solid conductive blind hole. It is easy to understand that the first blind holes 213 and the second blind holes 223 may have a one-to-one correspondence, and each first blind hole 213 is connected to a corresponding second blind hole 223 .

[0022] 102. Electroplating fills up the first blind hole,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com