Pre-milling system control method based on fuzzy intelligent control and optimization method

A technology of fuzzy intelligent control and optimization method, which is applied in general control system, control/regulation system, adaptive control, etc., can solve the problems of high energy consumption cost and low automation level, so as to improve the operation rate of equipment and facilitate online Effect of running, simplifying modeling steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

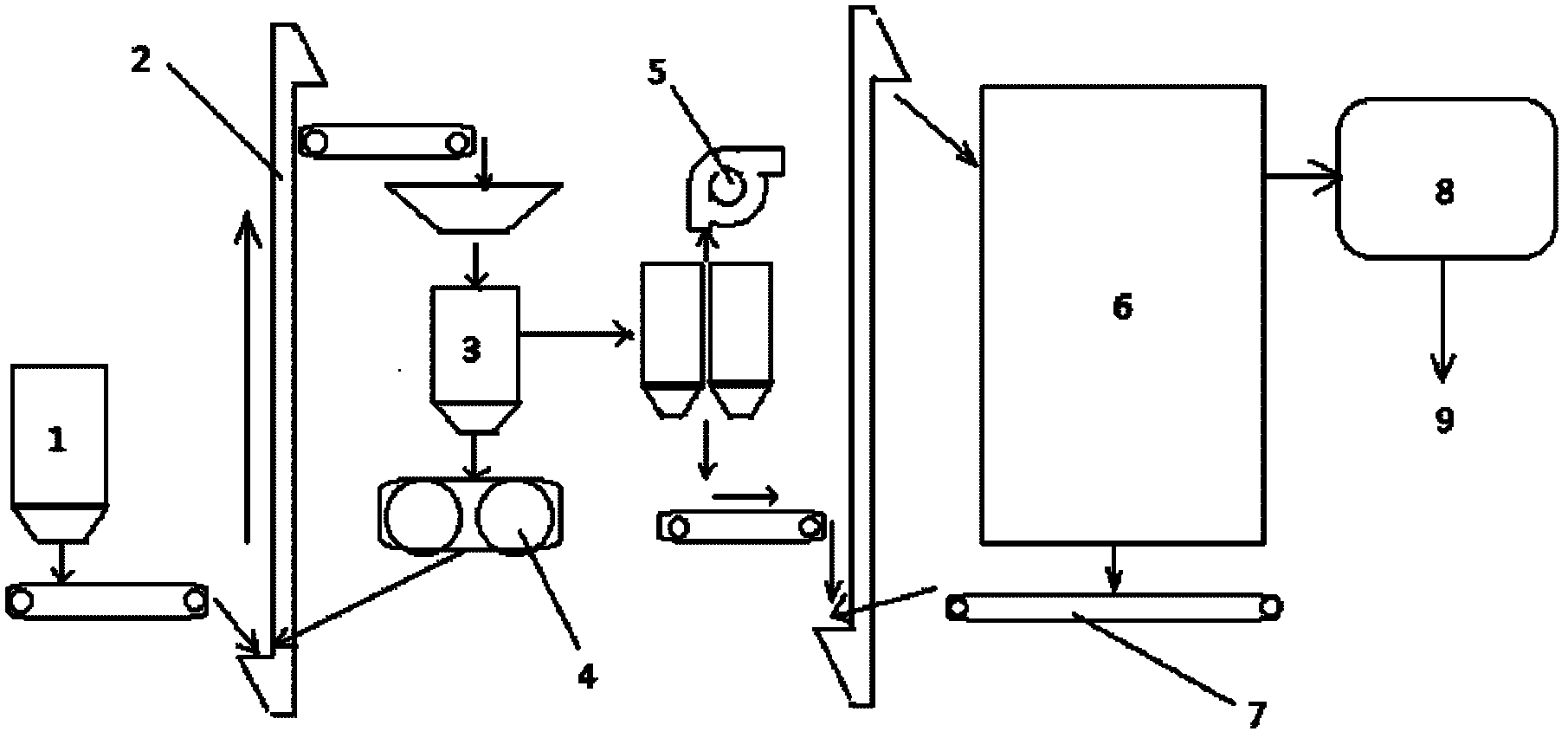

[0050] The purpose and effects of the present invention will become more apparent by referring to the accompanying drawings in detail of the present invention.

[0051] The general technical scheme that the present invention adopts is:

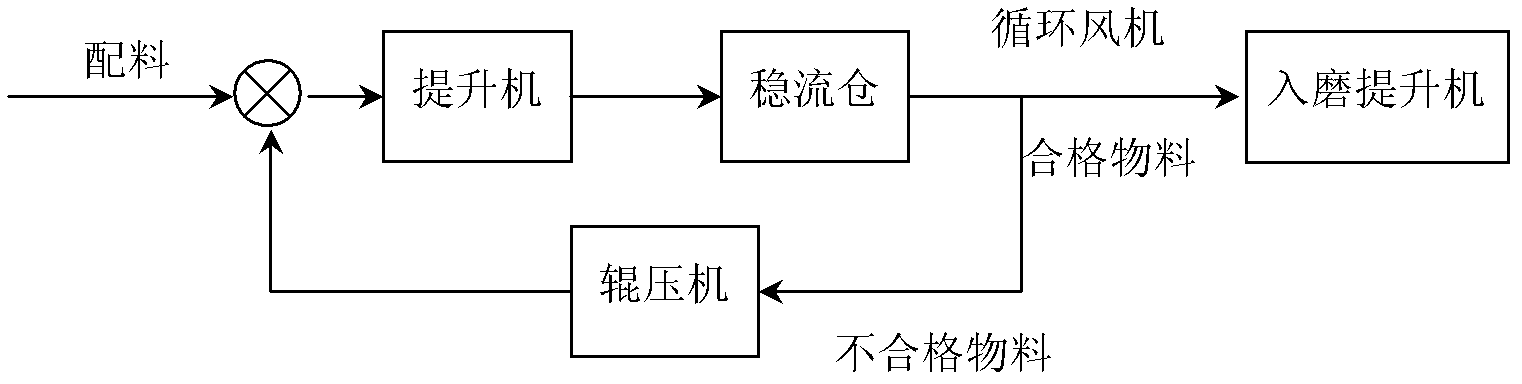

[0052] 1) The pre-grinding system is divided into two control loops: the steady flow bin weight control loop and the cycle load control loop. The weight control loop of the steady flow warehouse includes the following process: the ingredients enter the steady flow warehouse through the elevator, and after the action of the circulating fan, the qualified materials enter the mill elevator and are sent to the grinding system, and the unqualified materials enter the roller press, and are then rolled. Then enter the hoist together with the ingredients again. The steady flow warehouse weight control loop is as follows: figure 2 shown. The cyclic load control loop includes the following process: the qualified material in the steady flow bin enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com