Turbine

A technology of turbines and impellers, used in gas turbine installations, lubrication of turbine/propulsion installations, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

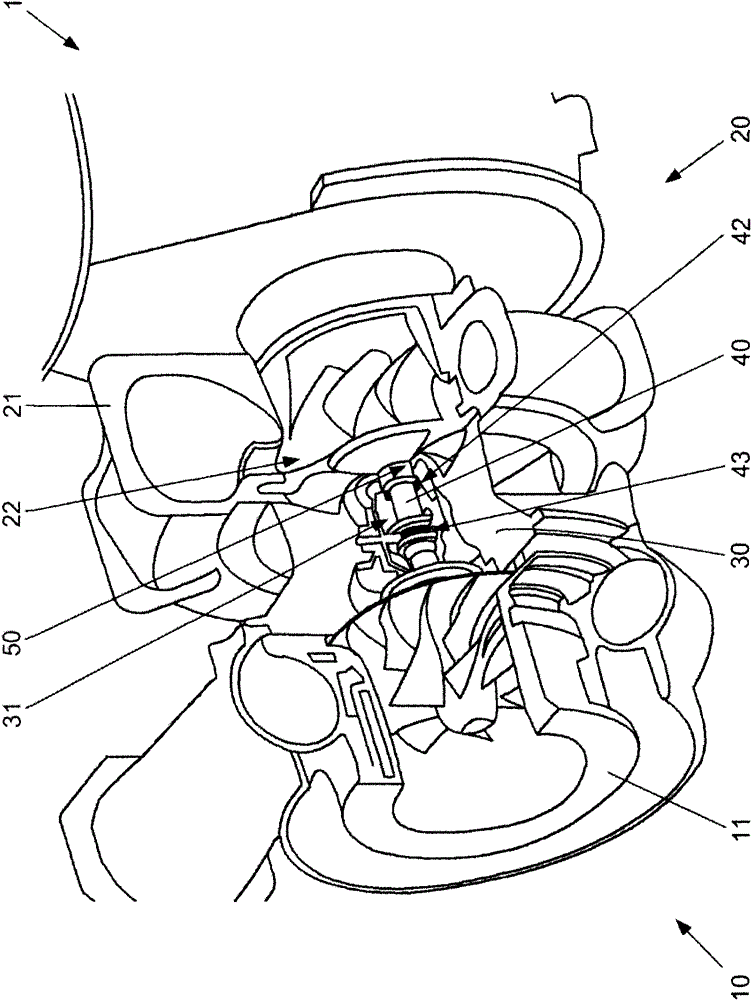

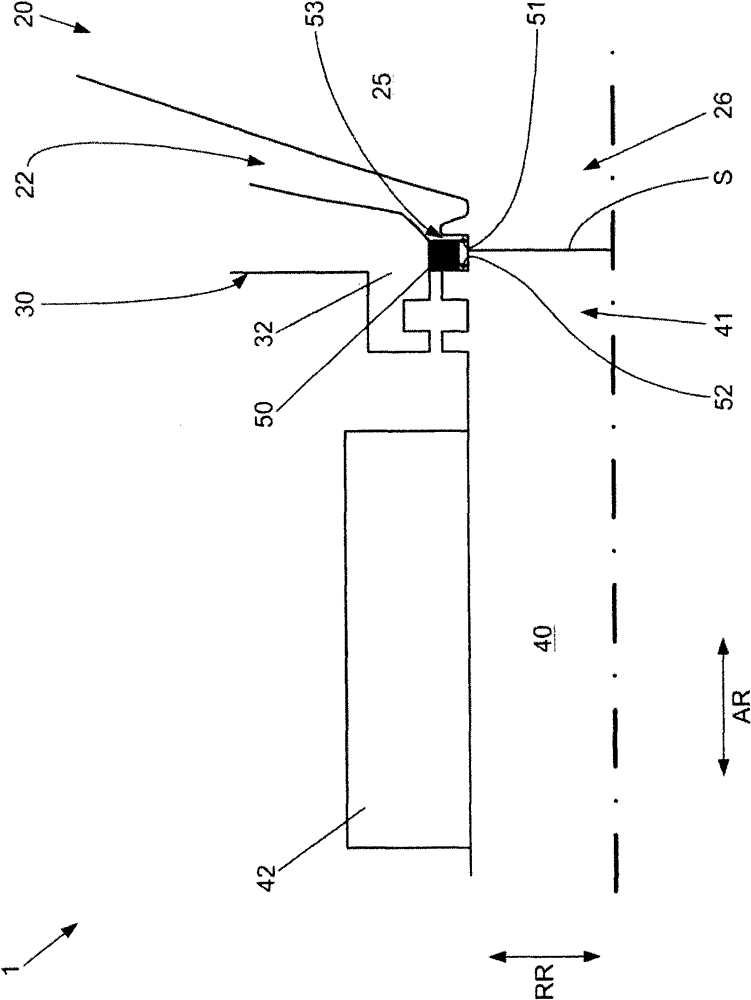

[0078] Refer below figure 1 with 3 A first embodiment of the present invention is described.

[0079] The turbomachine 1 according to the invention is designed in the form of a turbocharger with a turbocompressor 10 and an exhaust gas turbine 20 . The turbomachine 1 has a compressor housing 11 , a turbine housing 21 and a bearing housing 30 connecting the compressor housing 11 to the turbine housing 21 , which is made of ductile iron.

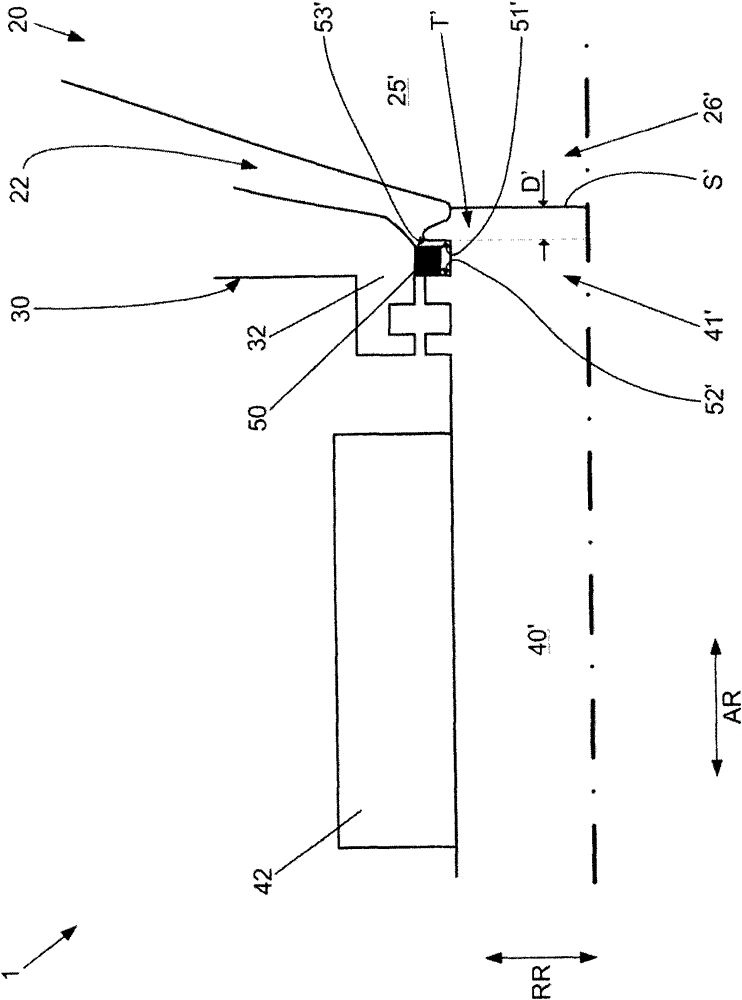

[0080] The turbine 1 also has a shaft 40' made of steel, which is rotatably supported in a bearing housing via a plurality of rotary bearings 42, 43 (here two radial sliding bearings 42 and one axial sliding bearing 43). 30 in the inner chamber 31 (also known as the oil chamber).

[0081] Such as image 3 As shown, on the axial end 41' of the shaft 40', there is a working impeller 25' of the exhaust gas turbine 20, which is materially connected to the axial end 41' of the shaft 40' by a weld S', and it The rotor chamber 22 of the turbine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com