Composite sandstone board and preparation method and application thereof

A technology of sandstone slabs and sandstones, which is applied in the field of composite sandstone slabs and its preparation, can solve the problems of affecting the appearance of decorations, difficulty in installation, and easy weathering loss, etc., and achieves the effects of simple and energy-saving preparation methods, easy installation, and not easy to be weathered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

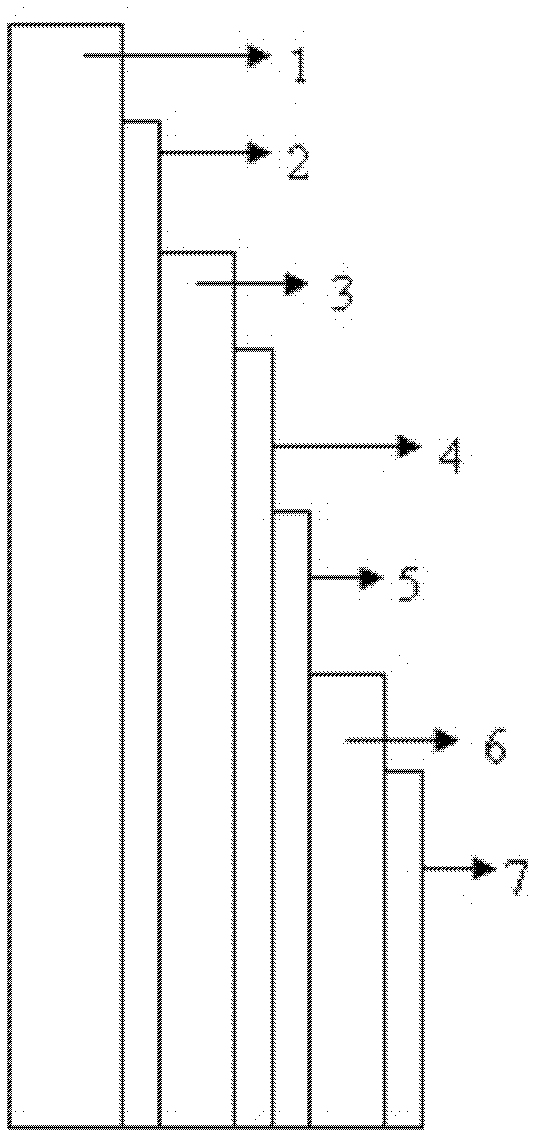

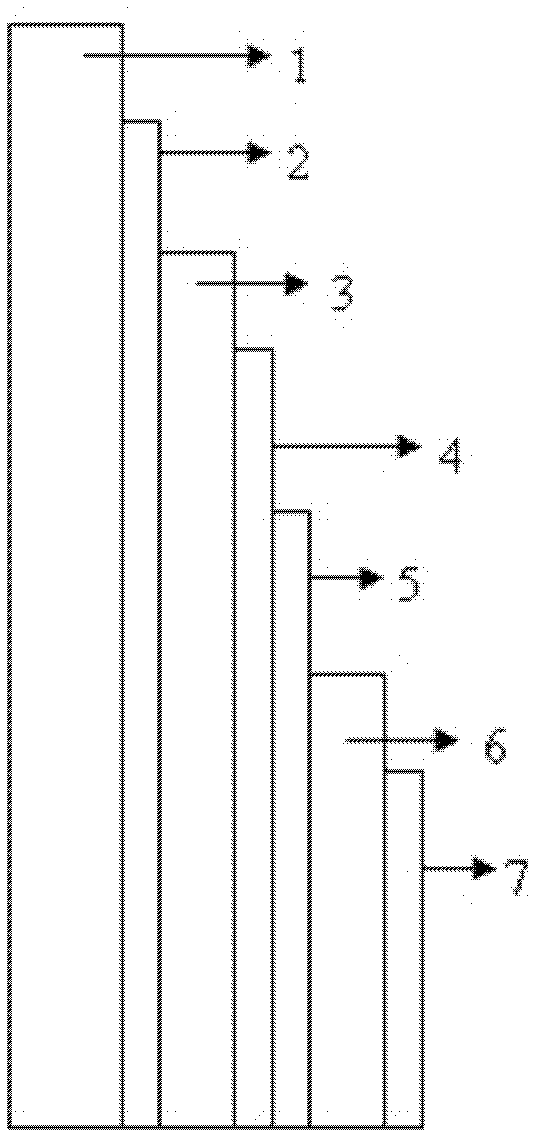

Image

Examples

Embodiment 1

[0027] A method for preparing a composite sandstone slab, comprising the following steps:

[0028] (1) Brush the sandy primer on the cement fiberboard, the thickness of the sandy primer layer is 30 μm; after 6 hours, evenly coat the first layer of sandstone on the sandy primer layer by the machine mold, the first layer The thickness of the sandstone layer is 1mm, and the surface of the sandstone layer is required to be smooth without unevenness;

[0029] (2) Spread the texture effect of the paint on the first layer of sandstone through a pre-made sandstone-effect screen. After the paint is completely dry, apply a layer of transparent pure acrylic emulsion. The thickness of the pure acrylic emulsion layer is 20μm;

[0030] (3) After the transparent pure acrylic emulsion is completely dry, scrape the second layer of sandstone. The thickness of the second layer of sandstone layer is 0.8mm. Use sandstone with high transparency and a particle size of 0.5-1mm to make the sandstone ...

Embodiment 2

[0032] A method for preparing a composite sandstone slab, comprising the following steps:

[0033] (1) Brush the sandy primer on the calcium silicate board, the thickness of the sandy primer layer is 10 μm; after 6 hours, evenly coat the first layer of sandstone on the sandy primer layer by the machine mold, the second The thickness of a layer of sandstone layer is 2mm, and the surface of the sandstone layer is required to be smooth and free of unevenness;

[0034] (2) Spread the texture effect on the first layer of sandstone through the pre-fabricated sandstone effect copper. After the paint is completely dry, spray a layer of transparent silicone acrylic emulsion. The thickness of the transparent silicone acrylic emulsion layer is 10μm;

[0035] (3) After the transparent pure acrylic emulsion dries up, scrape the second layer of sandstone. The thickness of the second layer of sandstone layer is 1mm. Use sandstone with high transparency and particle size of 0.5-1mm. It is s...

Embodiment 3

[0037] A method for preparing a composite sandstone slab, comprising the following steps:

[0038] (1) Brush the primer with sand on the ceramic slab, and the thickness of the primer layer with sand is 40 μm; after 6 hours, apply the first layer of sandstone evenly on the primer layer with sand by the machine mold, the first The thickness of the sandstone layer is 0.5mm, and the surface of the sandstone layer is required to be smooth and free of unevenness;

[0039] (2) Apply the texture effect on the first layer of sandstone through the pre-made sandstone-effect inkjet. After the ink is completely dry, roll on a layer of transparent styrene-acrylic emulsion. The thickness of the transparent styrene-acrylic emulsion layer 40μm;

[0040] (3) After the transparent pure acrylic emulsion is completely dry, scrape the second layer of sandstone. The thickness of the second layer of sandstone layer is 0.5mm. Use sandstone with high transparency and a particle size of 0.5-1mm to make...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com