Method for preparing biomass polylol by using ultrasonic waves and application thereof

A biomass polyol, ultrasonic technology, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problems of insufficient liquefaction reaction, troublesome operation, low yield, etc., and reduce the yield of liquefaction , the effect of fast liquefaction rate and high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

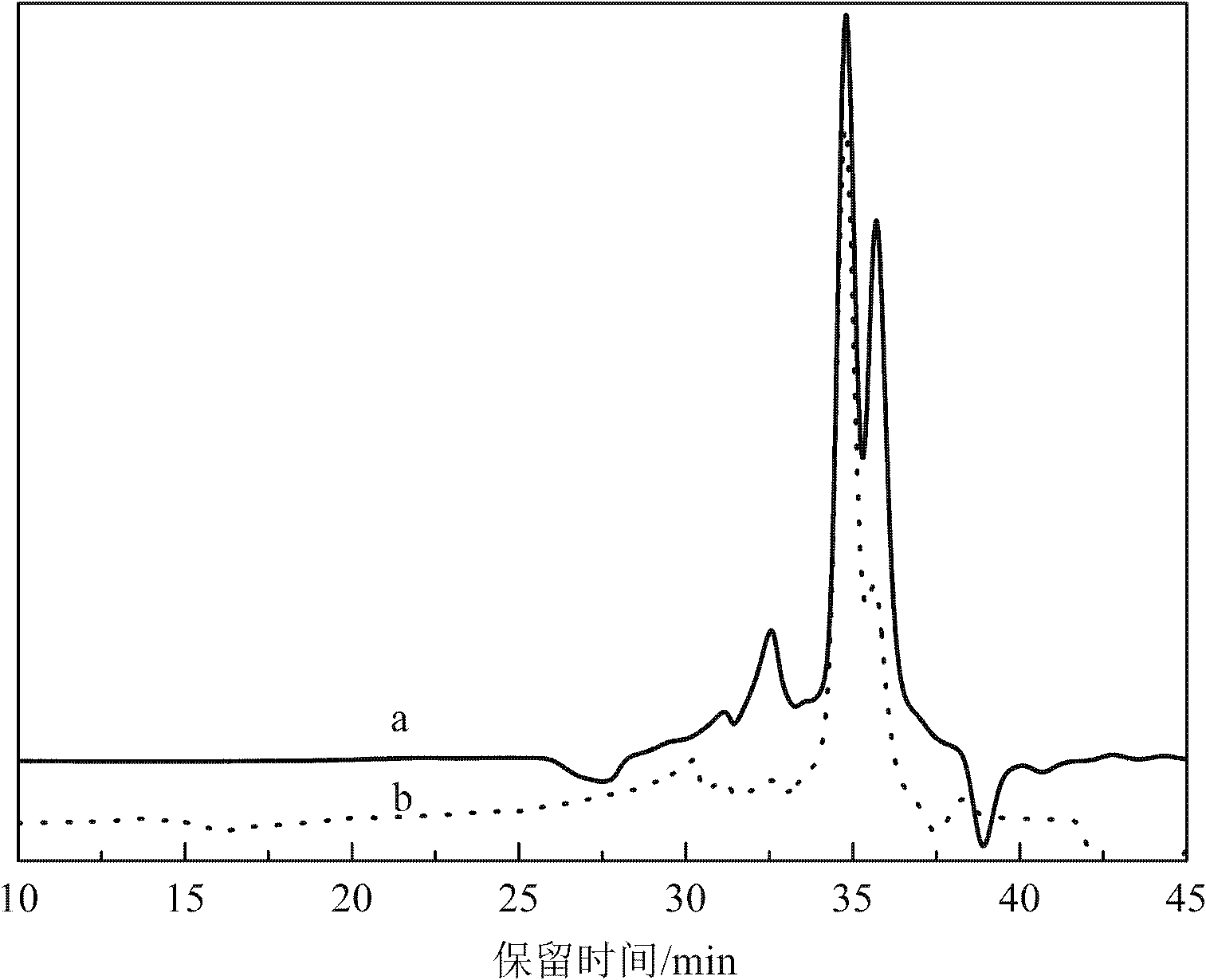

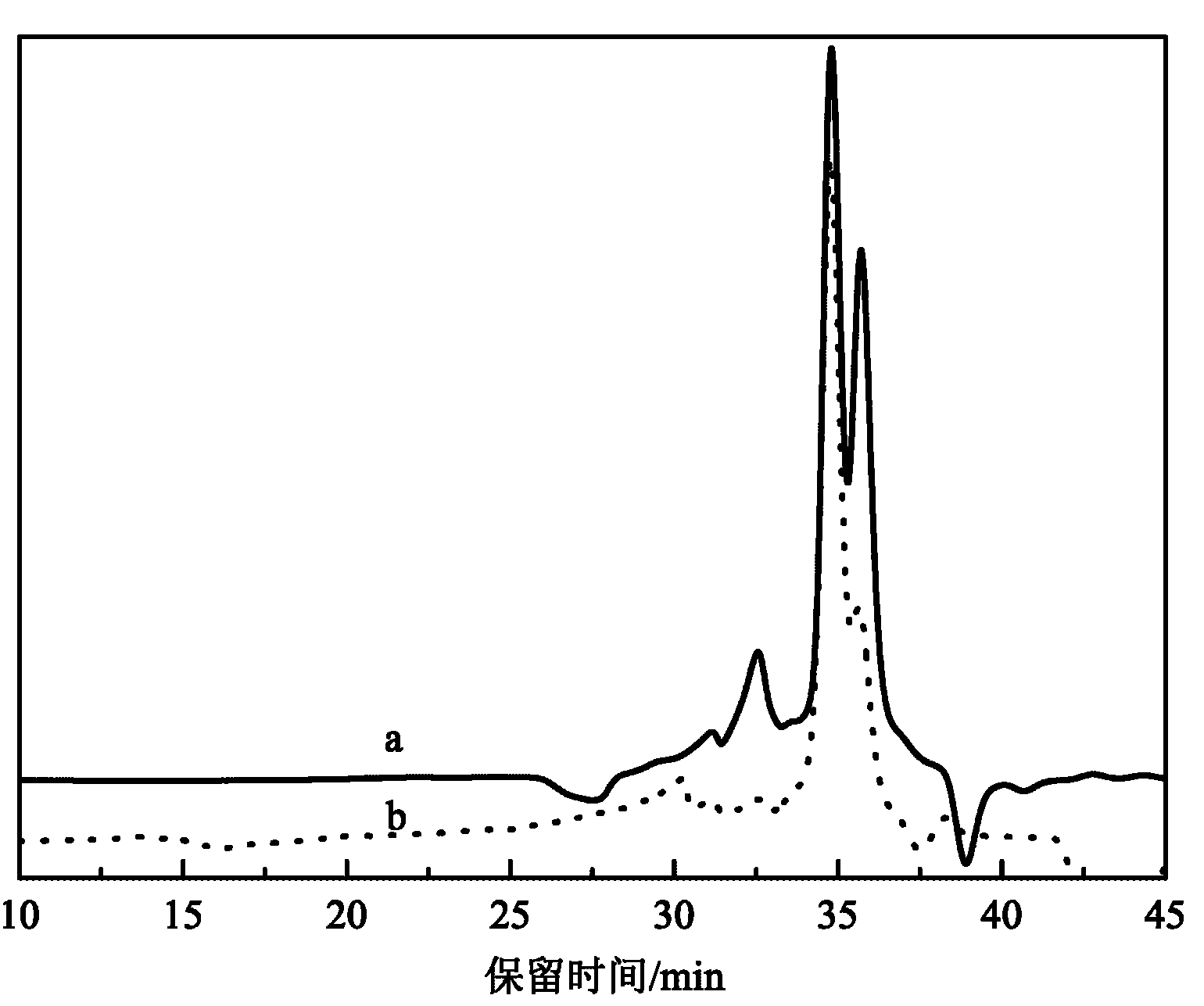

Image

Examples

Embodiment 1

[0025] Add 80g of ethylene glycol, 20g of glycerol and 3g of p-toluenesulfonic acid into a three-necked flask equipped with a condenser tube, stir it mechanically to make it evenly mixed, add 20g of poplar wood powder (100 mesh) under stirring, and then Place in an ultrasonic cell pulverizer with an ultrasonic power of 850W and an ultrasonic frequency of 20kHz. After ultrasonication for 10 minutes, the three-neck flask was placed in a mixed solution of ice and water to cool and terminate the reaction. The yield of the obtained liquefied product (i.e. biomass polyol) was 90.7% by mass, the viscosity was 550-1100 mPa·S, and the hydroxyl value was 440- 680mgKOH / g (the determination of yield and hydroxyl value is according to the literature (Zhang Hairong, Ji Hongguo, Shi Jinzhi, etc. Research on the organic sulfonic acid catalyzed thermochemical liquefaction of eucalyptus powder. Forestry Chemistry and Industry, 2010, 30 (6): 35- 39) to carry out, the measurement of viscosity is ...

Embodiment 2

[0027] Add 80g of ethylene glycol, 20g of glycerol and 3g of sulfuric acid into a three-necked flask equipped with a condenser, first use mechanical stirring to make it evenly mixed, add 20g of bagasse (60 mesh) under stirring, and then place it in an ultrasonic In the cell pulverizer, the ultrasonic power is 750W, and the ultrasonic frequency is 30kHz; after ultrasonic 60min, the three-neck flask is placed in the ice-water mixture to cool and terminate the reaction, and the yield of the obtained liquefied product (i.e. biomass polyol) is 97.7%, and the viscosity is 435~1000mPa·S, hydroxyl value 320~460mg KOH / g.

Embodiment 3

[0029] Add 100g of phenol and 3g of p-toluenesulfonic acid into a three-necked flask equipped with a condenser, first use mechanical stirring to make it evenly mixed, add 20g of bamboo powder (80 mesh) under stirring, and then place it in an ultrasonic cell pulverizer In the process, the ultrasonic power is 1500W, and the ultrasonic frequency is 20kHz; after ultrasonication for 40min, the three-necked flask is placed in a mixture of ice and water to cool and terminate the reaction. ·S.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com