Preparation method of graphene

A graphene and graphite technology, applied in the field of nanomaterials, can solve the problems of large amount of reducing agent, long reaction period and incomplete reduction, and achieve the effects of less amount of reducing agent, short reaction period and easy separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

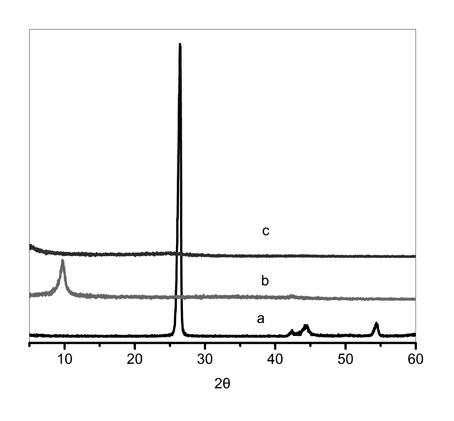

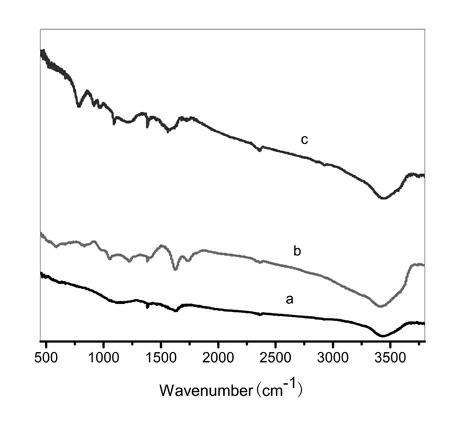

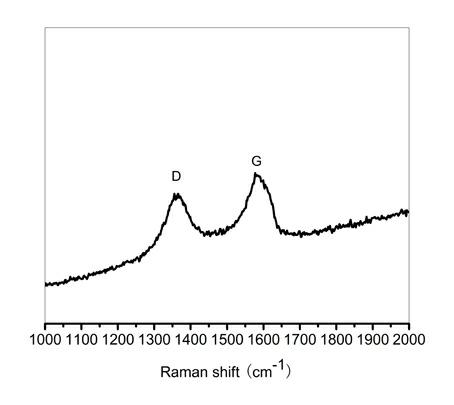

Image

Examples

preparation example Construction

[0026] Preparation of graphite oxide:

[0027] Weigh 5g of graphite powder and 2.5g of sodium nitrate and add them to 115mL of concentrated sulfuric acid (mass concentration 98%) in an ice-water bath, add 15g of potassium permanganate while stirring, and stir the mixture for 0.5h under ice-water bath conditions; Slowly raise the temperature to 35°C for 3h, then add 15g of potassium permanganate, heat up to 45°C for 12h; add 800mL of deionized water, stir at 20°C for 1h, then dropwise add 30mL of 30% (mass concentration) peroxide Hydrogen, stir for 0.5h; filter the above solution, wash with 500mL 10% (mass concentration) hydrochloric acid solution to remove metal ions, and then wash with a large amount of deionized water to remove excess acid and wash until neutral.

[0028] Drying: vacuum-dry the above-mentioned filtered product at 70° C. for 24 hours to obtain graphite oxide.

Embodiment 1

[0030] Weigh 2g of dry graphite oxide and place it in a quartz tube, evacuate until the degree of vacuum reaches 0.1MPa, raise the temperature to 300°C at a heating rate of 50°C / min, and expand the graphite oxide to obtain exfoliated graphite oxide.

[0031] Dissolve 1 g of sodium metal in 100 mL of liquid ammonia to obtain an alkali metal / liquid ammonia solution with a concentration of 10 mg / mL, add 1 g of the above-mentioned thermally expanded and exfoliated graphite oxide to it, and stir for 0.5 h; add 50 mL of ethanol and stir for 0.5 h, Suction filtration, washing with 100 mL of diethyl ether, and finally washing with 200 mL of deionized water, and vacuum drying at 70°C for 24 hours to obtain graphene powder.

Embodiment 2

[0033] Weigh 2g of dry graphite oxide and place it in a quartz tube, evacuate until the degree of vacuum reaches 0.1MPa, raise the temperature to 500°C at a heating rate of 100°C / min, and expand the graphite oxide to obtain exfoliated graphite oxide.

[0034] Dissolve 3g of metallic calcium in 100mL of liquid ammonia to obtain an alkaline earth metal / liquid ammonia solution with a concentration of 30mg / mL, add 1g of thermally expanded and exfoliated graphite oxide to it, and stir for 2h. Add 100mL of methanol and stir for 0.5h, filter with suction, wash with 200mL of ether, and finally wash with 200mL of deionized water, and dry in vacuum at 60°C for 24h to obtain graphene powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com