Method for improving rare earth grade of rare earth ore

A rare earth ore, grade technology, applied in solid separation, flotation and other directions, can solve the problems of difficult to prepare high grade, high recovery rare earth concentrate, low mineral dissociation degree, coarse mineral particle size, etc., to increase the cost , Improve the recovery rate, the effect of high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

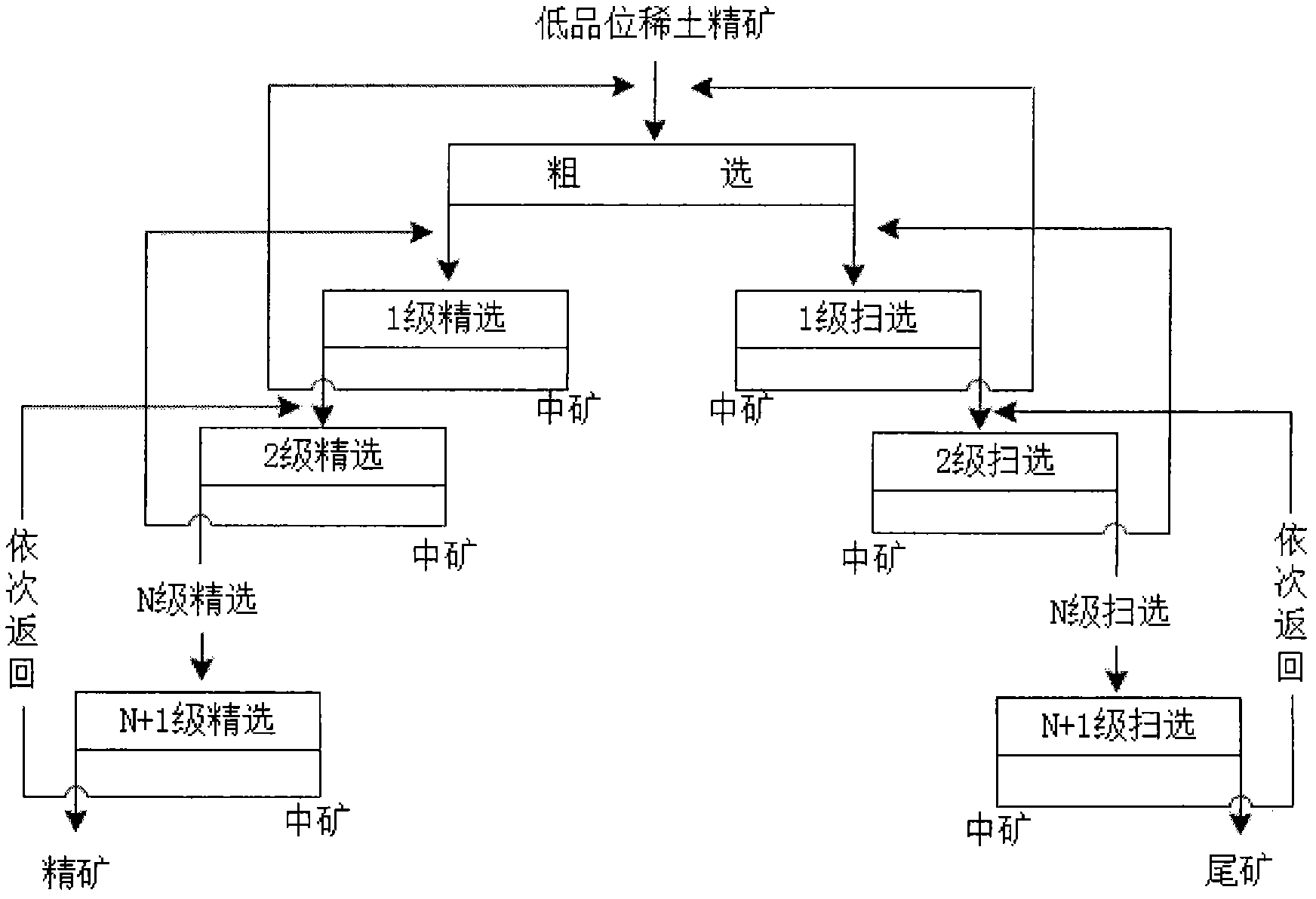

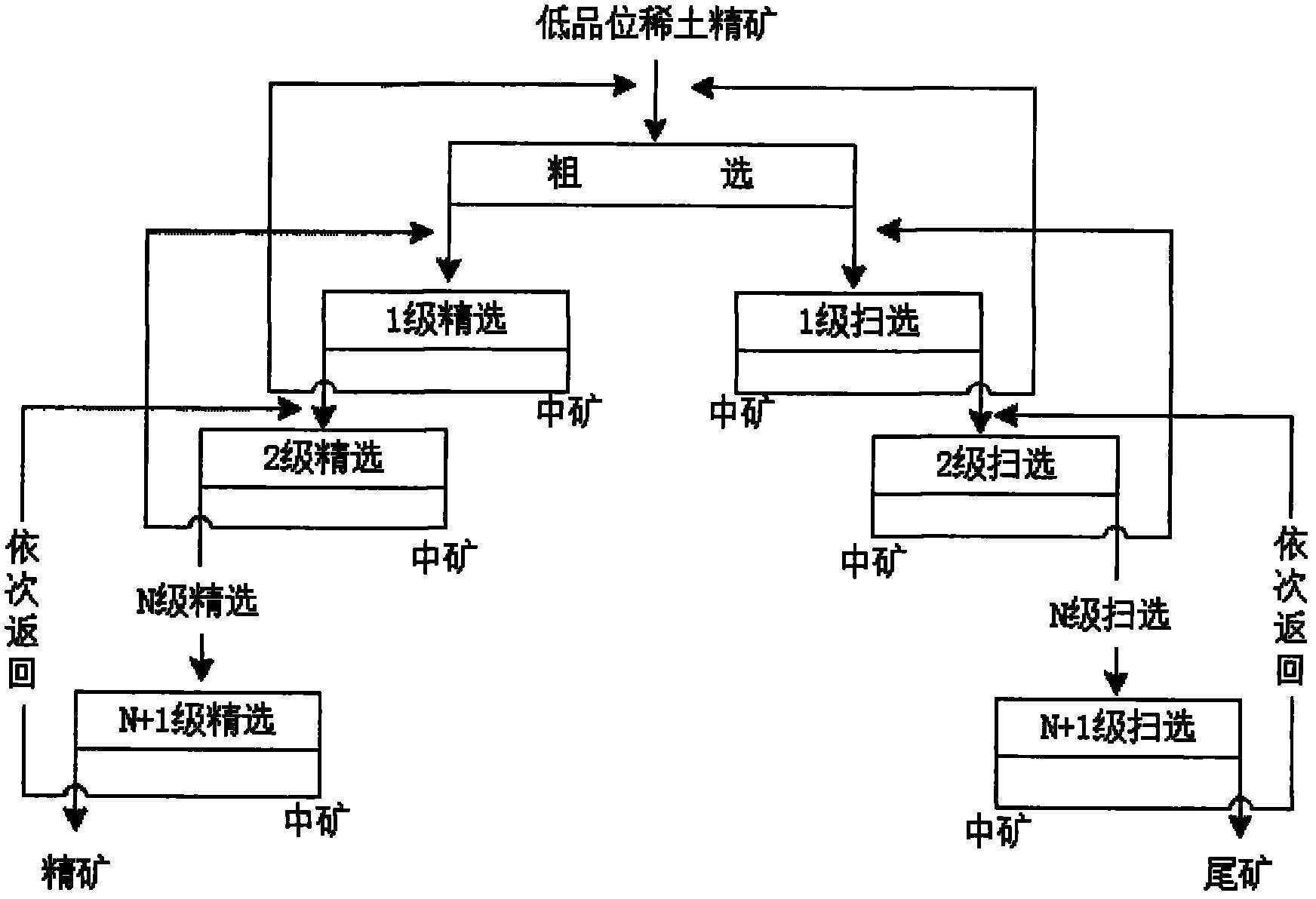

Image

Examples

Embodiment 2

[0030]The Baiyan Obo mixed rare earth concentrate with a rare earth grade of 30.52% and a particle size of -200 mesh, accounting for more than 98%, uses the technology of the present invention to formulate a closed-circuit circulation mineral processing process of one roughing, four beneficiation and one sweeping .

[0031] 1) Rough separation: Add the rare earth concentrate with a rare earth grade of 30.52% and the two medium ores produced by the first stage of beneficiation and the first stage of sweeping into the flotation tank, add water to mix and adjust the pulp to make the pulp quality The concentration is controlled at 65% and stirring is started. The temperature of the pulp is 70°C; while stirring, 0.5kg / t of water glass, LF8#1.8kg / t, 318 is 0.12kg / t, and the pH of the pulp is 8.5. Carry out roughing under certain conditions to obtain roughing concentrate and roughing tailings. The roughing concentrate continues to be first-stage beneficiation, and the roughing tailin...

Embodiment 3

[0038] The Baiyan Obo mixed rare earth concentrate with a rare earth grade of 55.54% and a particle size of -200 mesh accounting for more than 98% uses the technology of the present invention to formulate a process flow for primary roughing, secondary beneficiation and secondary sweeping.

[0039] The amount of reagents added during flotation is calculated by weight ratio: rough selection: water glass 2.6kg / t, H2052.5kg / t, 318 is 0.18kg / t; first fine: water glass 0.9kg / t, H2051.4kg / t , 318 is 0.05kg / t; Erjing: water glass 0.6kg / t, H2051.0 / t, 318 is 0.04kg / t; sweep: water glass 0.4kg / t, H2050.8kg / t, 318 is 0.05 kg / t; second sweep: water glass 0.2kg / t, H2050.7kg / t, 318 is 0.02kg / t; third sweep: water glass 0.4kg / t, H2050.5kg / t, 318 is 0.02kg / t. The mass concentration of the roughing pulp is controlled at 52%, the pulp temperature is 48°C, and the pH of the pulp is 9.6; the mass concentration of the refined pulp is controlled at 55%, the pulp temperature is 56°C, and the pH of th...

Embodiment 4

[0041] The Baiyan Obo mixed rare earth concentrate with a rare earth grade of 50.16% and a particle size of -200 mesh accounting for more than 98% uses the technology of the present invention to formulate a process flow for primary roughing, secondary beneficiation and secondary sweeping.

[0042] The amount of reagents added during flotation is calculated by weight ratio: rough selection: water glass 4.0kg / t, LF8#3.0kg / t, 318 is 0.12kg / t; first fine: water glass 2.0kg / t, LF8#1.8kg / t, 318 is 0.08kg / t; Erjing: water glass 1.5kg / t, LF8#1.5 / t, 318 is 0.05kg / t; sweep: water glass 0.8kg / t, LF8#1.8kg / t, 318 is 0.06kg / t; second sweep: water glass 0.6kg / t, LF8#0.8kg / t, 318 is 0.04kg / t. The mass concentration of the roughing pulp is controlled at 55%, the pulp temperature is 45°C, and the pH of the pulp is 9.5; the mass concentration of the refined pulp is controlled at 55%, the pulp temperature is 40°C, and the pH of the pulp is 9.5; the mass concentration of the sweeping pulp is con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com