Preparation method of Baoxin tablet

A technology of Baoxin tablets and diaphragm pressure filtration, which can be applied to medical preparations containing active ingredients, pharmaceutical formulations, cardiovascular system diseases, etc., and can solve the problems of cumbersome process, high energy consumption, and troublesome post-processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Prescription: Sanqi 450g, Danshen 5.4kg, Chuanxiong 3.6kg, Hawthorn 4.5kg, Polygonum multiflorum 1.575kg, Polygonum multiflorum 2.925kg

[0045] The preparation method comprises the following steps:

[0046] a. Extraction of Polygonum multiflorum

[0047] a1. Crush the Polygonum Polygoni Multiflori in the prescribed amount into a coarse powder and set aside;

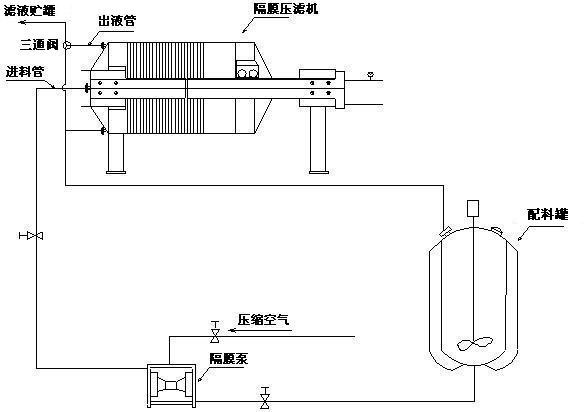

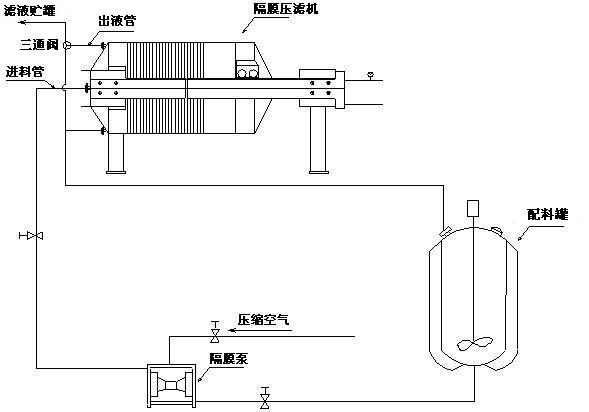

[0048] a2. Add 60% ethanol equivalent to 7 times the weight of Polygonum multiflorum in the batching tank; switch the three-way valve to the batching tank position, open the agitator, diaphragm pump and diaphragm filter press of the batching tank, pump the 60% ethanol in the batching tank into the membrane filter press (using 5-8 L / m 2 .s polypropylene multifilament filter cloth), until the filtrate returns to the batching tank, add the powder obtained in step a1 into the batching tank at a constant speed, after the addition, the membrane filter press cycle extracts for 30 minutes, and then switch the three-w...

Embodiment 2

[0062] Prescription: Sanqi 450g, Danshen 5.4kg, Chuanxiong 3.6kg, Hawthorn 4.5kg, Polygonum multiflorum 1.575kg, Polygonum multiflorum 2.925kg

[0063] The preparation method comprises the following steps:

[0064] a. Extraction of Polygonum multiflorum

[0065] a1. Crush the Polygonum Polygoni Multiflori in the prescribed amount into a coarse powder and set aside;

[0066] a2. Add 60% ethanol equivalent to 6 times the weight of Polygonum multiflorum in the batching tank; switch the three-way valve to the batching tank position, open the agitator, diaphragm pump and diaphragm filter press of the batching tank, pump the 60% ethanol in the batching tank into the membrane filter press (using 5-8 L / m 2 .s polypropylene multifilament filter cloth), when the press filtrate flows back into the batching tank, add the medicine powder obtained in step a1 into the batching tank at a constant speed, after the addition is completed, the membrane filter press cycle extracts for 40 minu...

Embodiment 3

[0080] Prescription: Sanqi 450g, Danshen 5.4kg, Chuanxiong 3.6kg, Hawthorn 4.5kg, Polygonum multiflorum 1.575kg, Polygonum multiflorum 2.925kg

[0081] The preparation method comprises the following steps:

[0082] a. Extraction of Polygonum multiflorum

[0083] a1. Crush the Polygonum Polygoni Multiflori in the prescribed amount into a coarse powder and set aside;

[0084] a2. Add 60% ethanol equivalent to 8 times the weight of Polygonum multiflorum in the batching tank; switch the three-way valve to the batching tank position, open the agitator, diaphragm pump and diaphragm filter press of the batching tank, pump the 60% ethanol in the batching tank into the membrane filter press (using 5-8 L / m 2 .s polypropylene multifilament filter cloth), when the press filtrate flows back into the batching tank, add the medicinal powder obtained in step a1 into the batching tank at a constant speed, after the addition is completed, the membrane filter press cycle extracts for 35 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com