Growth promoting premix compound for shrimps and crabs and preparation method thereof

A growth-promoting and premixed material technology, which is applied in the fields of application, animal feed, animal feed, etc., can solve the problems of unreasonable nutritional models of the energy system, and achieve the effects of increasing autoimmune function, promoting synthesis and deposition, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Each raw material component shown in Table 1 is automatically weighed by electronic weighing system by weight, and each weighed raw material component is added in the mixer by the material delivery system and mixed for 10 minutes, so that the uniformity (in the mixed feed The uniformity of mixing of various raw materials is determined according to GB / T 5918) to 5%, and the mixture is obtained. The particle size is such that it can pass through a 30-mesh sieve, and the coefficient of variation is 6.5%. The resulting mixture is packaged to obtain a finished product.

Embodiment 2

[0018] Each raw material component shown in Table 1 is automatically weighed by electronic weighing system by weight, and each weighed raw material component is added in the mixer by the material delivery system and mixed for 5 minutes, so that the uniformity reaches 5%. Obtain the mixture, and its particle size is to be able to pass through 30 mesh sieves, and the coefficient of variation is 6.6%, the mixture packaging that will make obtains finished product.

Embodiment 3

[0020] Each raw material component shown in Table 1 is automatically weighed by electronic weighing system by weight, and each weighed raw material component is added in the mixer by the material delivery system and mixed for 8 minutes, so that the uniformity reaches 5%. Obtain the mixture, and its particle size is to be able to pass through 30 mesh sieves, and coefficient of variation is 6.8%, the mixture packaging that will make obtains finished product.

[0021] Table 1 (unit: kilogram)

[0022]

[0023] Each raw material component shown in Table 1 is a commercially available product, and its manufacturer and specifications are shown in Table 2.

[0024]

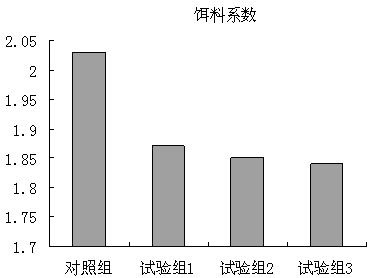

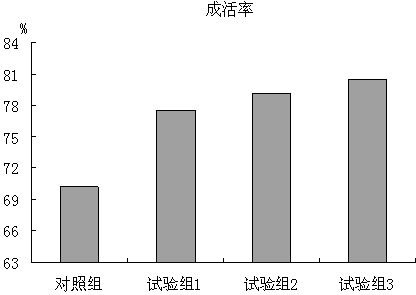

[0025] Illustrate effect of the present invention below by contrast test:

[0026] Add the growth-promoting premix for shrimp and crab produced in the above examples 1 to 3 and the existing shrimp and crab premix product (Shaanxi Kangsheng Biotechnology Co., Ltd., specification: 250g / bag) respectively in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com