Fabry-Perot (F-P) cavity and laser using same

A technology of F-P and lasers, applied in the field of lasers, can solve the problems of poor stability of F-P cavity, easy to be disturbed by the outside world, too large volume, etc., and achieve the effect of reducing the possibility of mode hopping, not easy to be disturbed by the outside world, and small in size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

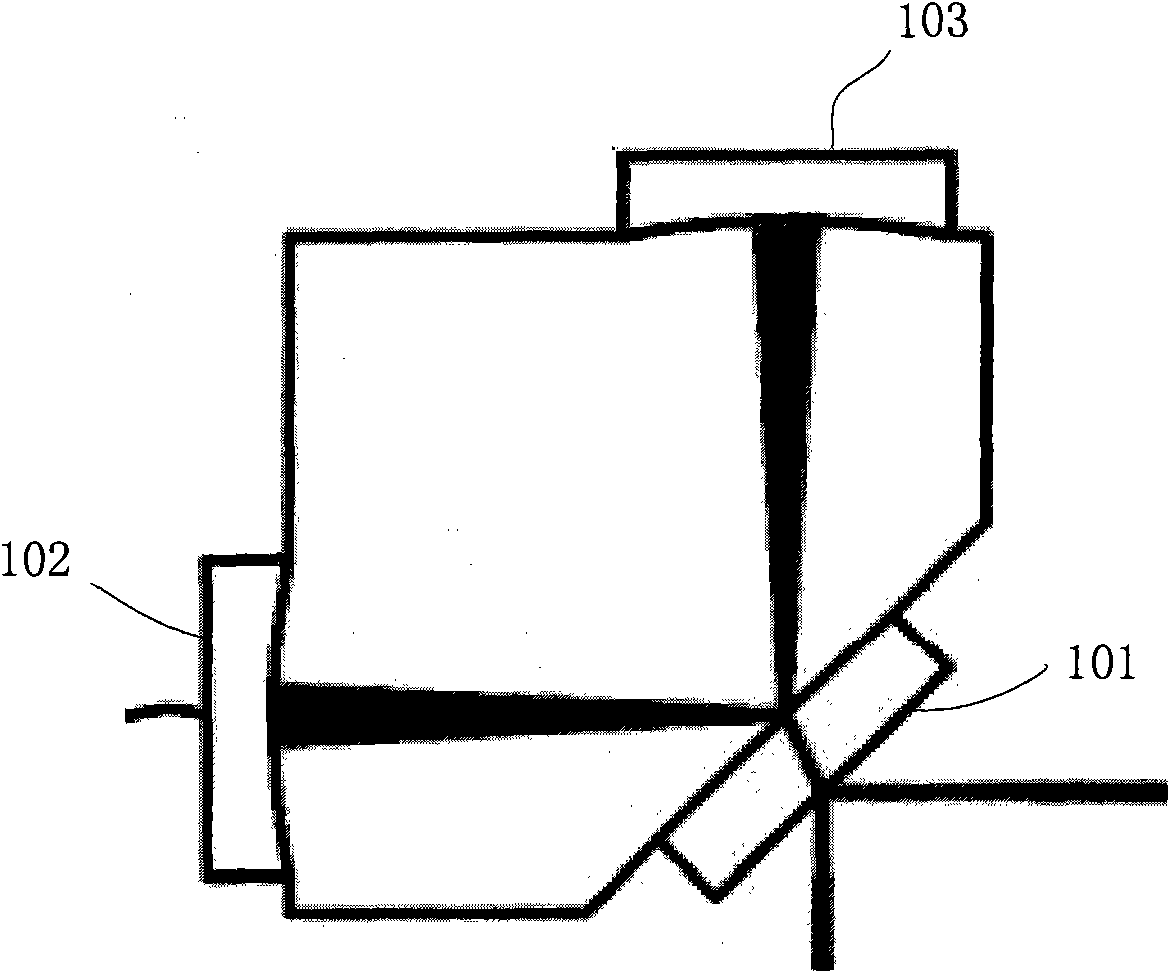

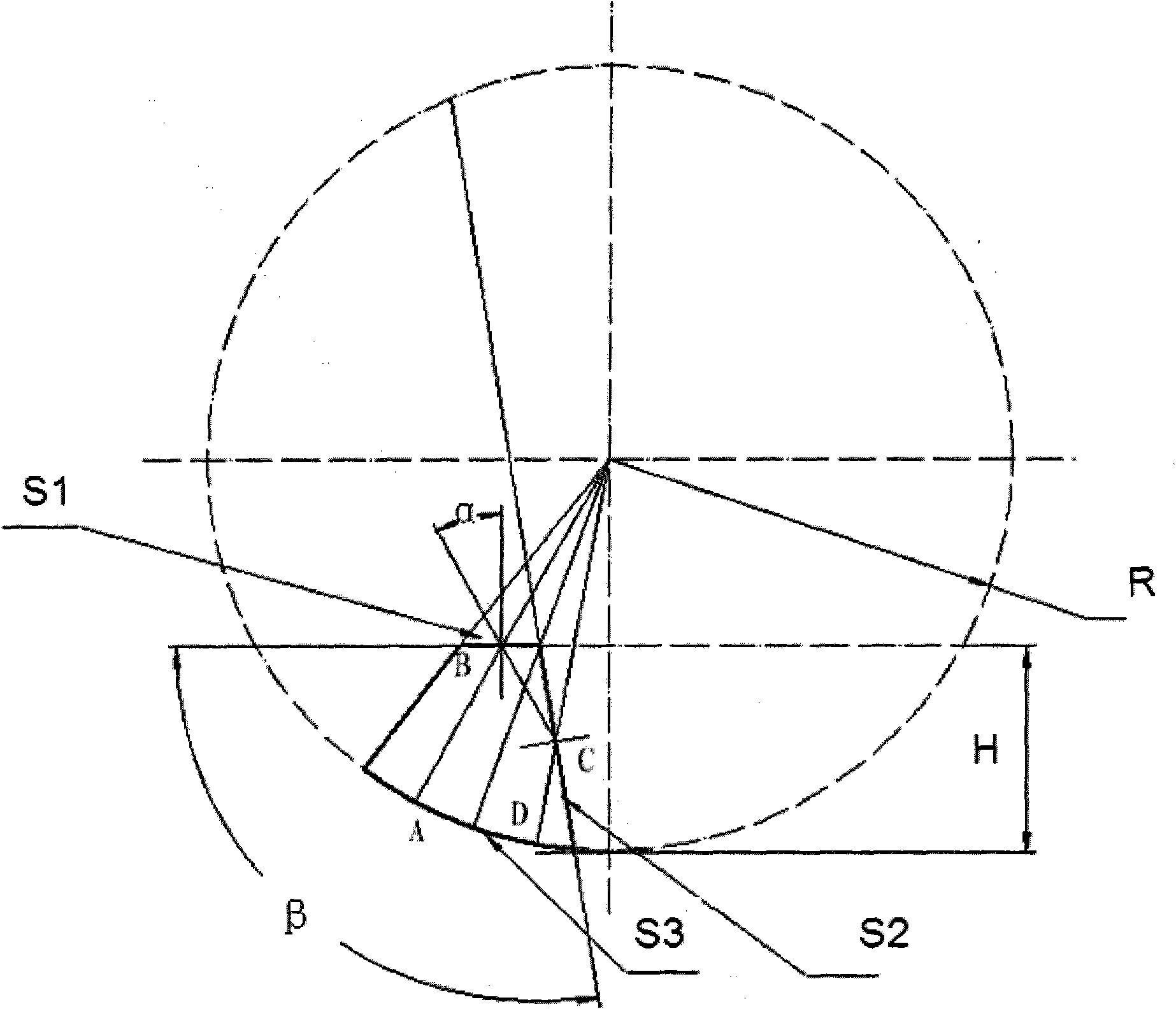

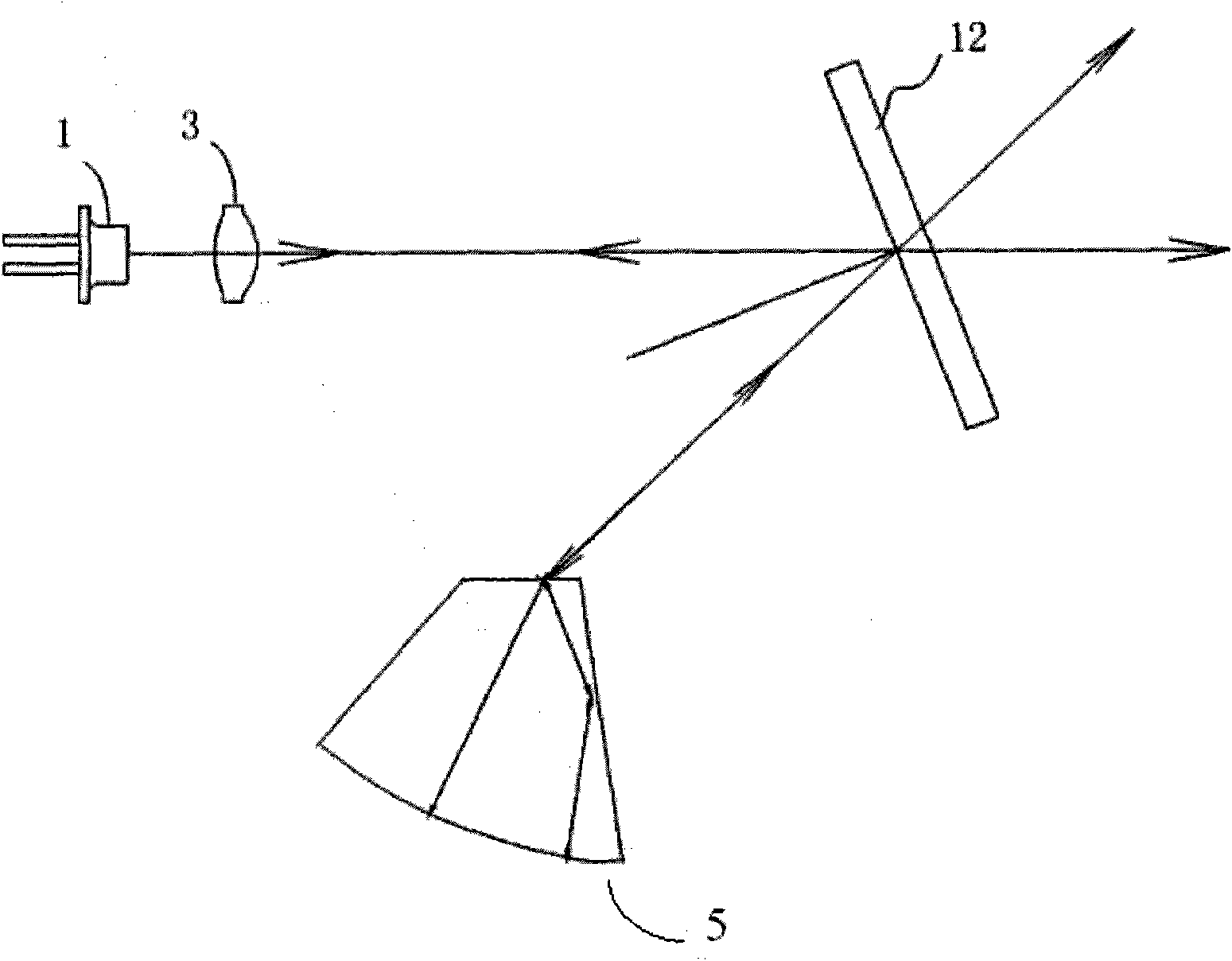

[0030] The applicant has found in long-term research and practice that the F-P cavity of the discrete component is easily disturbed and affected by external audio, mechanical vibration and temperature changes, the volume of the cavity is relatively large, and the stability of the system is relatively poor. At the same time, non-confocal F-P cavities are more complicated in operation than confocal F-P cavities because they need to perform mode matching for different input beams. When a good match is not achieved, multimode is prone to occur, which increases the possibility of mode hopping and affects the tracking and locking of the laser. The one-time folding confocal cavity needs to process two spherical mirrors to form a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com