Method for making storage unit of phase-change random access memory

A phase-change memory and storage unit technology, applied in electrical components and other directions, can solve the problems of lowering product yield, phase-change storage units not working properly, and poor thickness uniformity of the low-dielectric constant material layer 105, so as to avoid losses. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object, technical solution, and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

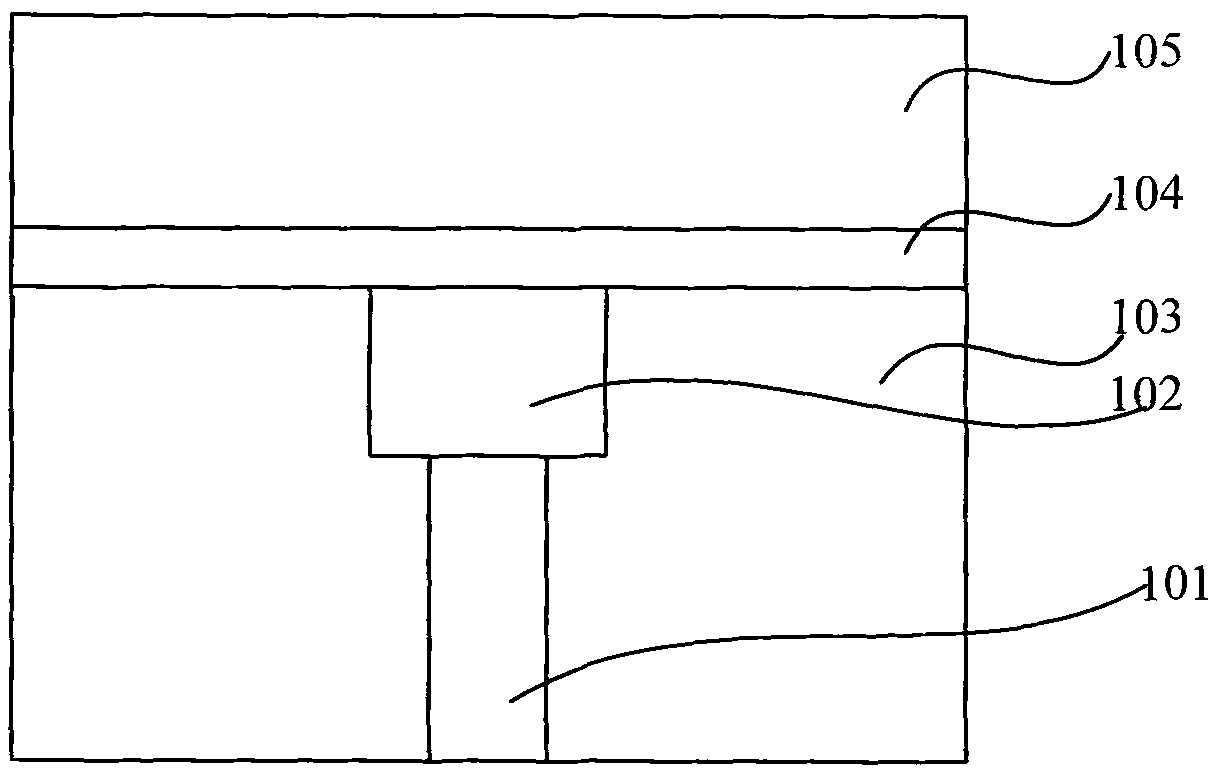

[0032] The core idea of the present invention is to deposit an etch stop layer on the surface of the phase change layer. The etch stop layer is a stack of three layers, which are a nitride layer, an oxide layer and a nitride layer in sequence. Due to the high etching selectivity of the etching gas between the nitride layer and the oxide layer, when etching between adjacent etch stop layers, gradually reduce the etching difference, and finally when the phase change layer is exposed, try to Avoid loss of phase change layer.

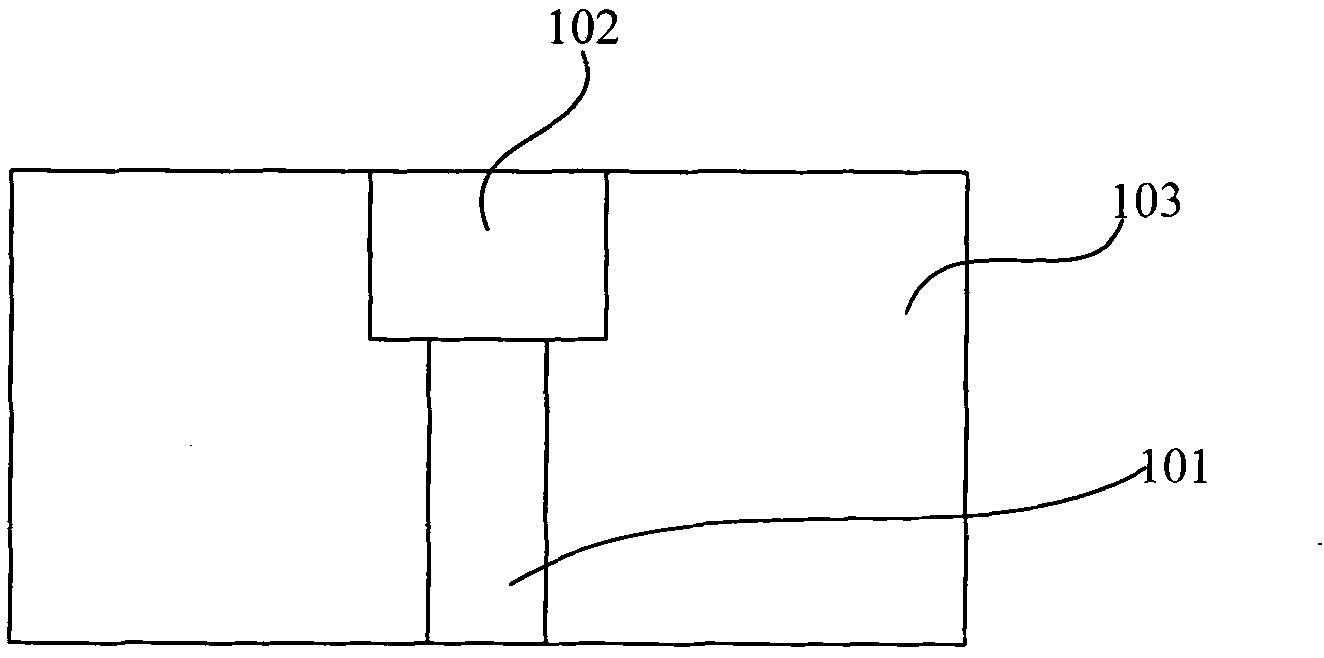

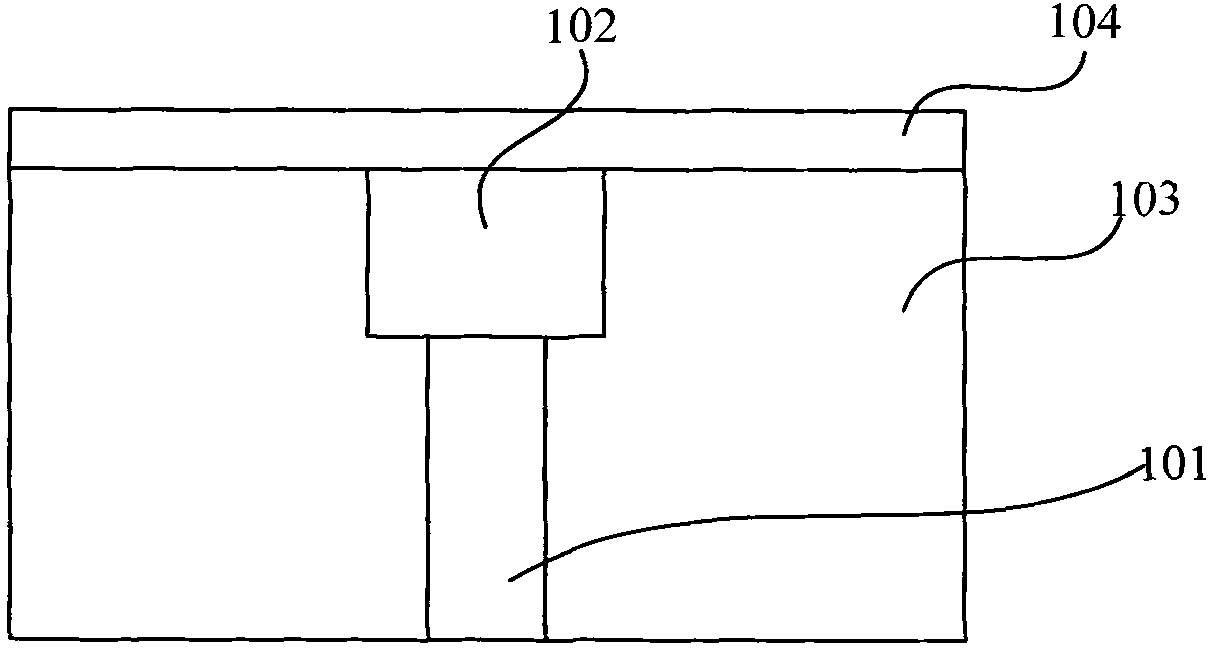

[0033] The invention discloses a method for manufacturing a storage unit of a phase-change memory, the schematic flow chart of which is as follows figure 2 As shown, the specific combination of Figure 2a to Figure 2i To illust...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com