Manufacturing process of silicon heterojunction solar battery

A solar cell and heterojunction technology, which is applied in the manufacture of circuits, electrical components, and final products, can solve problems such as uneven film thickness, difficult film formation, and difficult concentration control, and achieve the effect of avoiding uneven film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

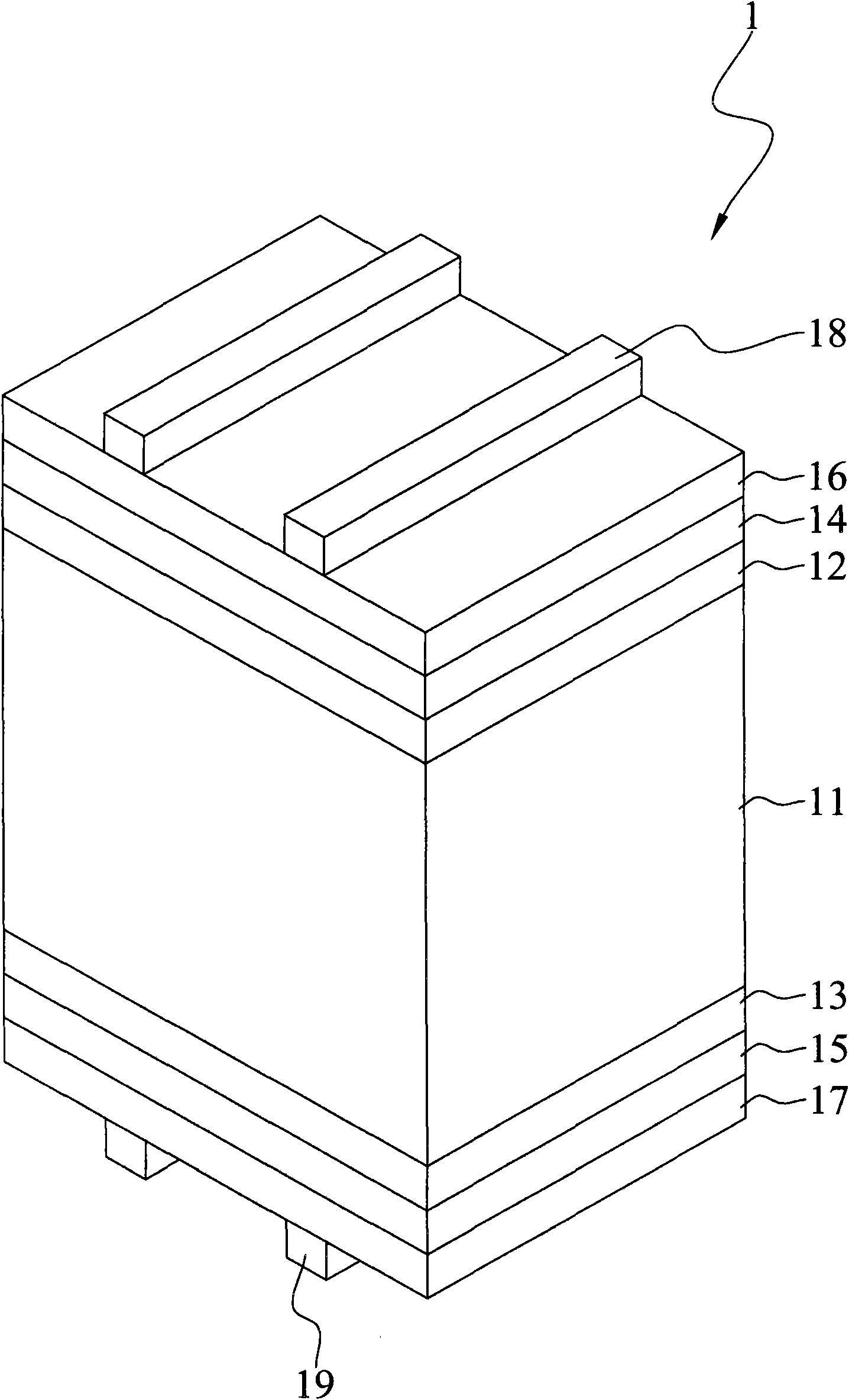

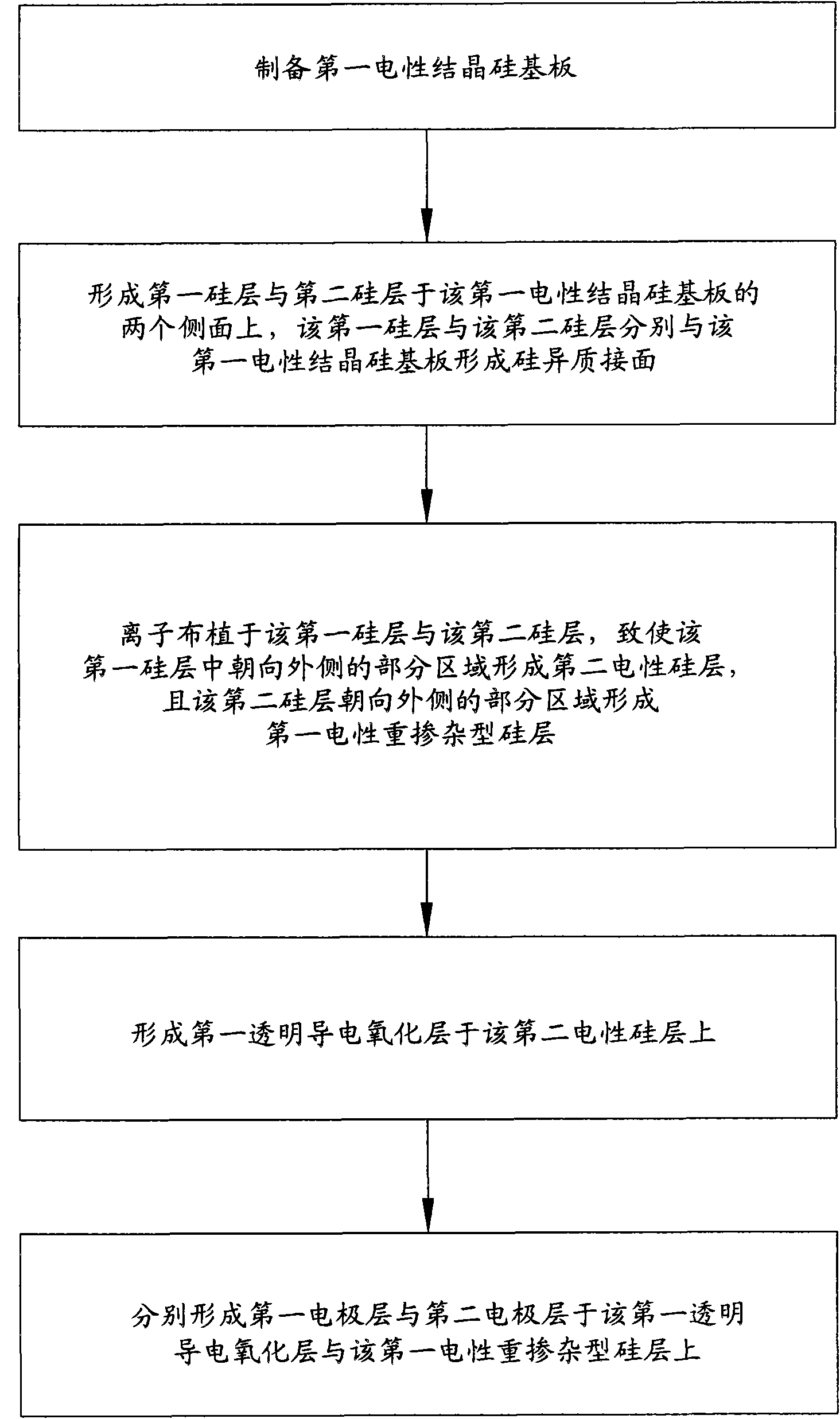

[0013] Relevant detailed description and technical content of the present invention, now coordinate drawing description as follows:

[0014] refer to figure 2 As shown, it is a flowchart of an embodiment of the present invention, as shown in the figure: the present invention proposes a process for manufacturing a silicon heterojunction solar cell, the steps of which include: preparing a first electrical crystalline silicon substrate; forming a second A silicon layer and a second silicon layer are on two sides of the first electrical crystalline silicon substrate, and the first silicon layer and the second silicon layer respectively form silicon heterojunctions with the first electrical crystalline silicon substrate ; Ions are implanted in the first silicon layer and the second silicon layer, so that the outer part of the first silicon layer forms the second electrical silicon layer, and the outer part of the second silicon layer forms the first silicon layer. An electrical h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com