Vertical type inner container-free double grate boiler

A double grate, vertical technology, used in steam boilers, water tube steam boilers, steam generation and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

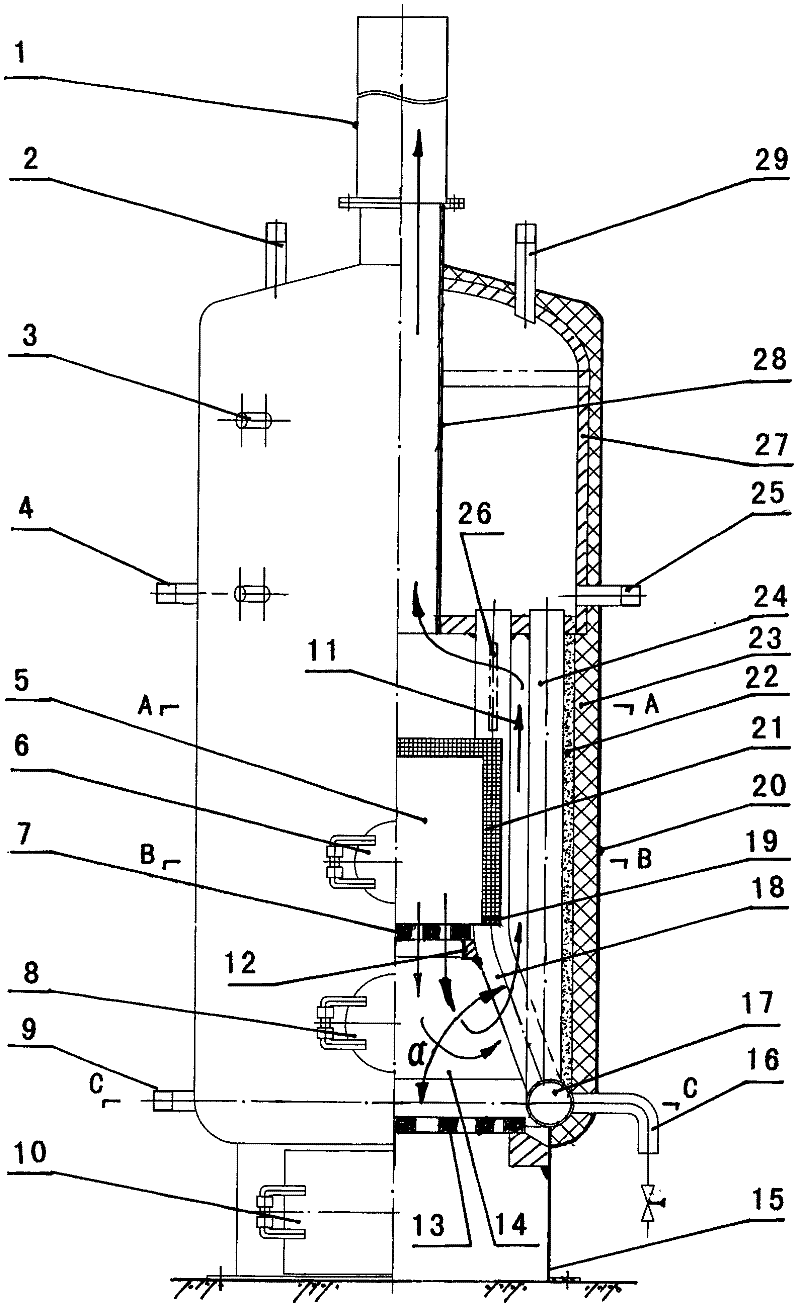

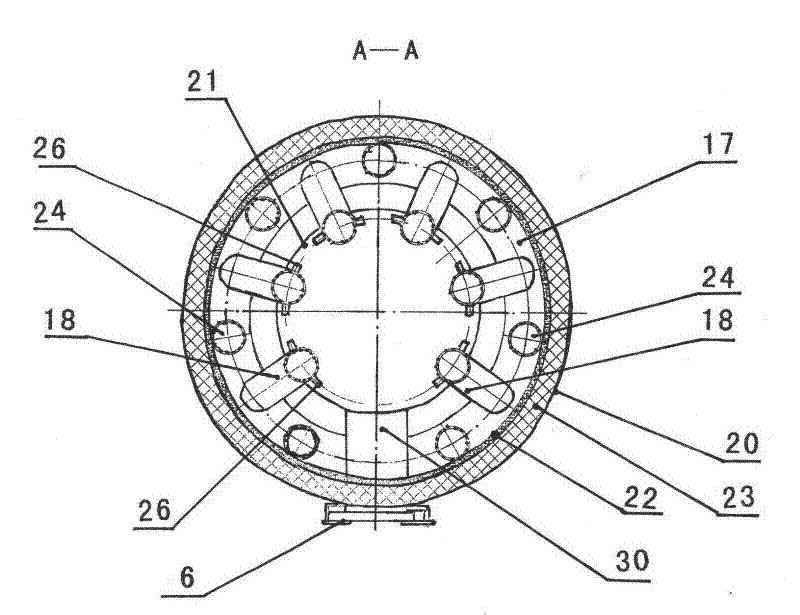

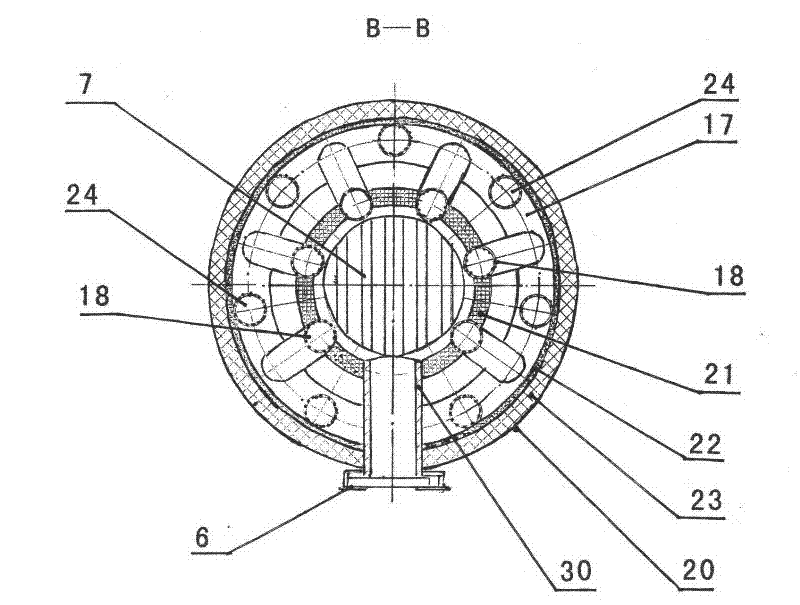

[0019] The embodiments of the present invention are further described below in conjunction with the drawings:

[0020] A vertical gallbladderless double-grate boiler, which is mainly composed of a furnace foot ring 15, a furnace shell 20, an annular header tube 17, an overhead steam drum 27, a smoke exhaust pipe 28, and a chimney connected to the smoke exhaust pipe 28 1. A set of outer convection pipes 24 and inwardly folded convection pipes 18 are formed. A slag cleaning furnace door 10 is provided on the side wall of the furnace leg ring 15, and a heat insulation layer 23 and a mixture are built on the inner wall of the furnace shell 20. The clay refractory layer 22 is equipped with hot water wire tube 25, main steam wire tube 29, pressure gauge wire seat 2, water level gauge wire seat 3, and water seal tube 4 on the top steam drum 27. A water inlet pipe 9 and a sewage pipe 16 are installed on the 17; the bottom ends of a group of outer convection pipes 24 and inwardly folded c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com