Vertical-pipe outer wall-heated non-pressure boiler

A boiler and standpipe technology, used in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of affecting the thermal efficiency of the boiler, reducing the thermal conductivity, and being unfavorable for energy saving, so as to increase the effective heat absorption area, The effect of improving thermal efficiency and reducing reactive heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

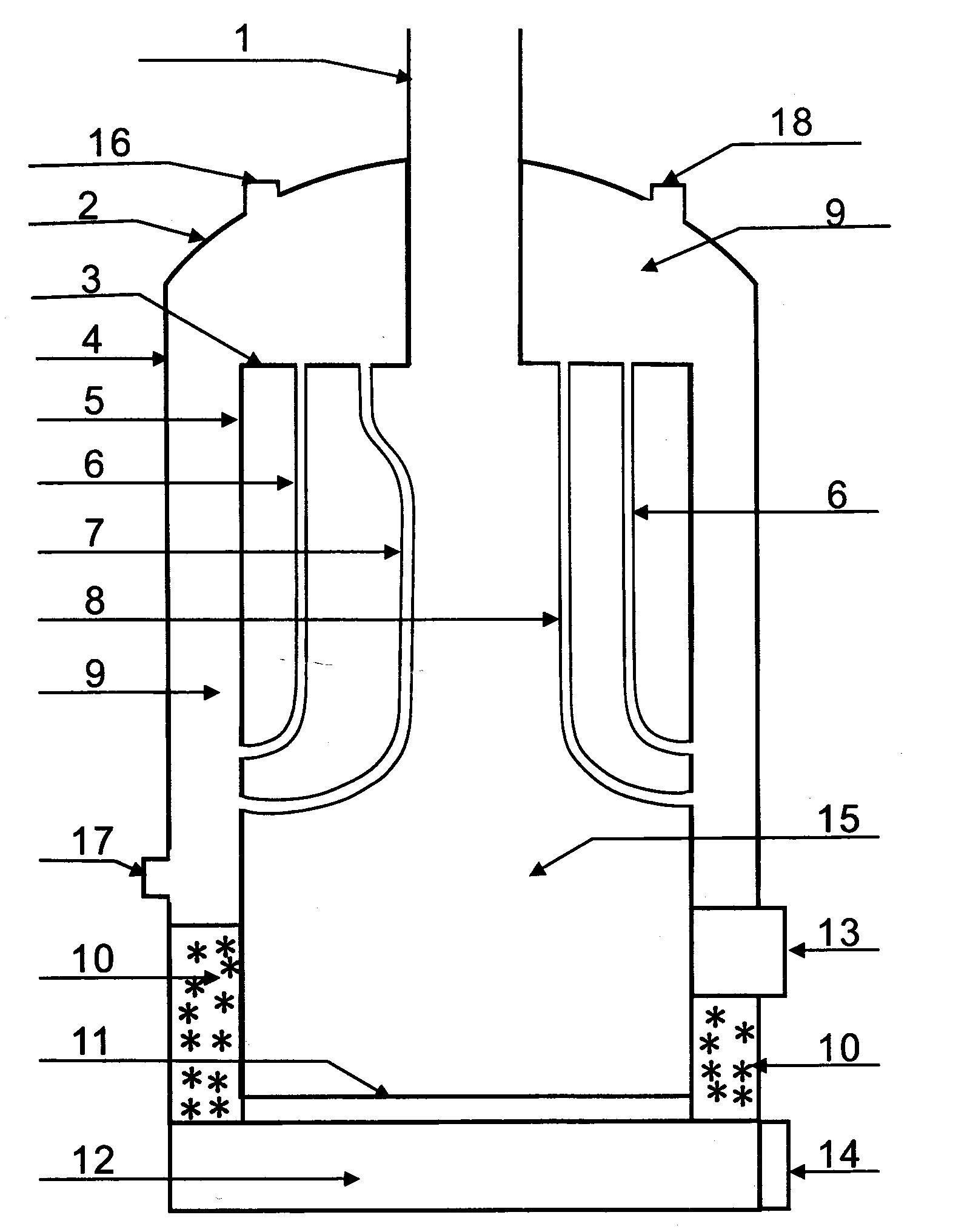

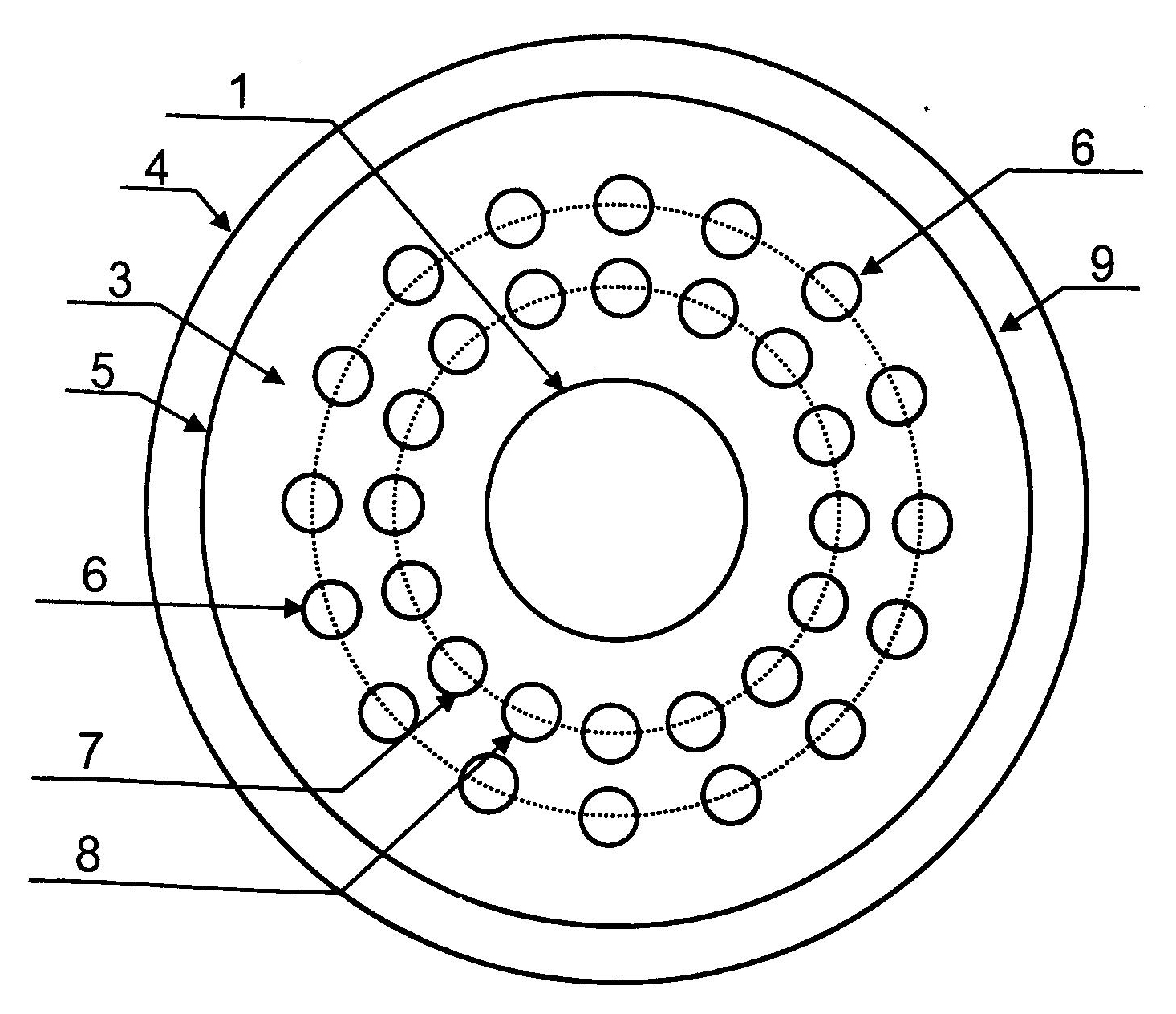

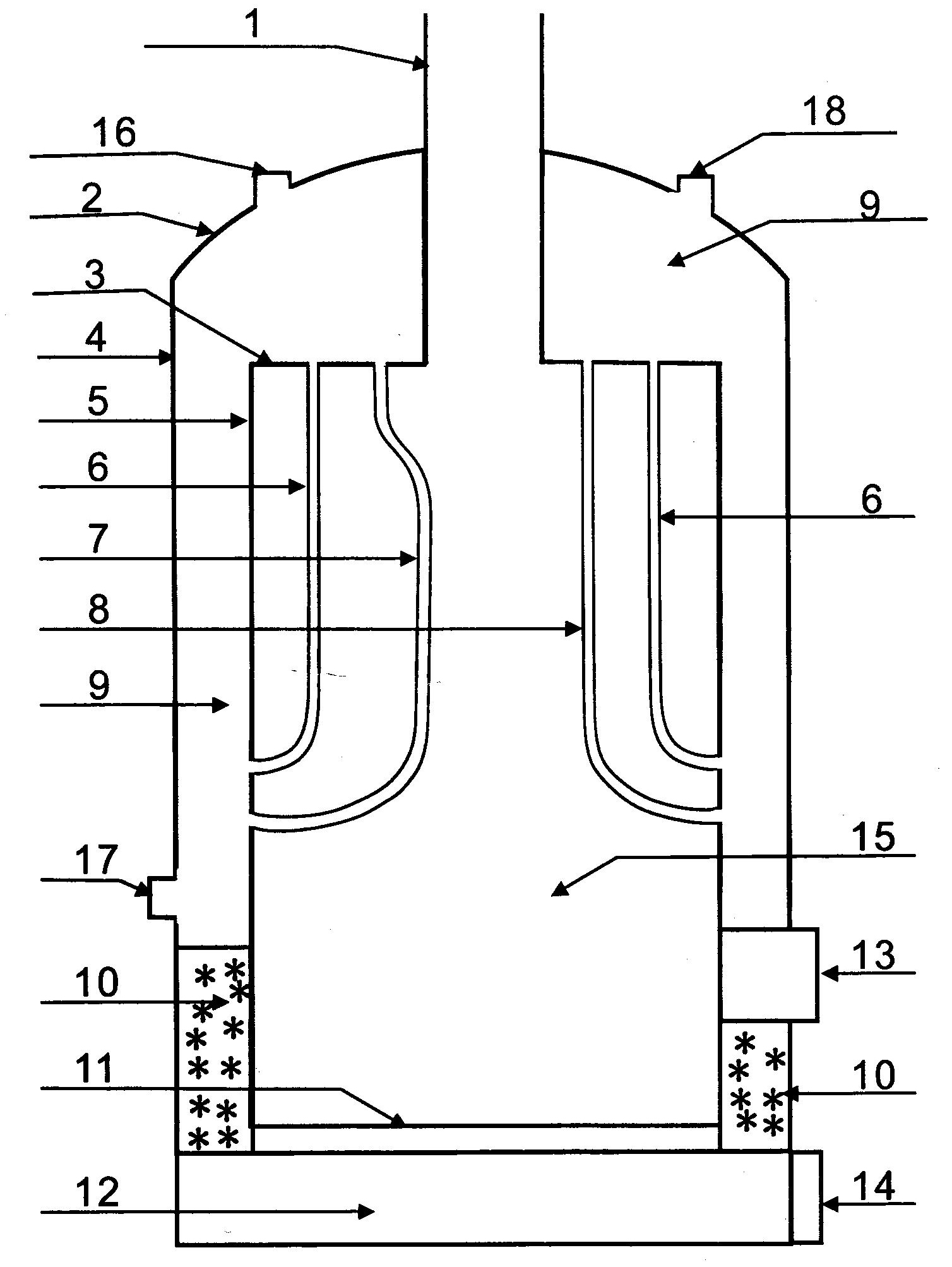

[0010] It can be seen from the accompanying drawings that the vertical tube outer wall heating type pressureless boiler includes a boiler body composed of an outer wall 4, an inner wall 5, a head 2, and a roof 3, as well as a chimney 1, an air passage port 16, a water outlet 18, a water return port 17, and a boiler body. Door 13, combustion chamber 15, furnace grate 11, slag chamber 12, slag outlet 14, "spoon" type heating pipe 7 and "L" type heating pipe 6,8. The chimney 1 is placed in the upper middle of the boiler body, the air passage port 16 and the water outlet 18 are placed on the head 2, a combustion chamber 15 is provided at the lower part of the boiler body, and a refractory concrete 10 is provided between the inner and outer walls of the combustion chamber. The boiler body corresponding to the combustion chamber 15 is provided with a fuel-filling furnace door 13, and the water return port 17 is placed on the lower side of the outer wall. The lower part of the combust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com