Four-impulse control method for steam drum water level of converter

A technology of steam drum water level and control method, which is applied in the direction of liquid level control, non-electric variable control, control/regulation system, etc., and can solve the problems of false water level alarm signal, insufficient water replenishment capacity, false water level, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The technical solution of the present invention will be further described below in conjunction with the drawings and embodiments.

[0051] See figure 1 As shown, figure 1 It is the structural diagram of the converter steam drum water level control system, where 1 is the steam drum, 8 is the steam drum inlet pump, 2 is the water inlet shut-off valve, 3 is the water inlet regulating valve, 4 is the sewage valve, 5 is the steam recovery valve, and 6 It is a steam relief valve, and 7 is a steam supply valve.

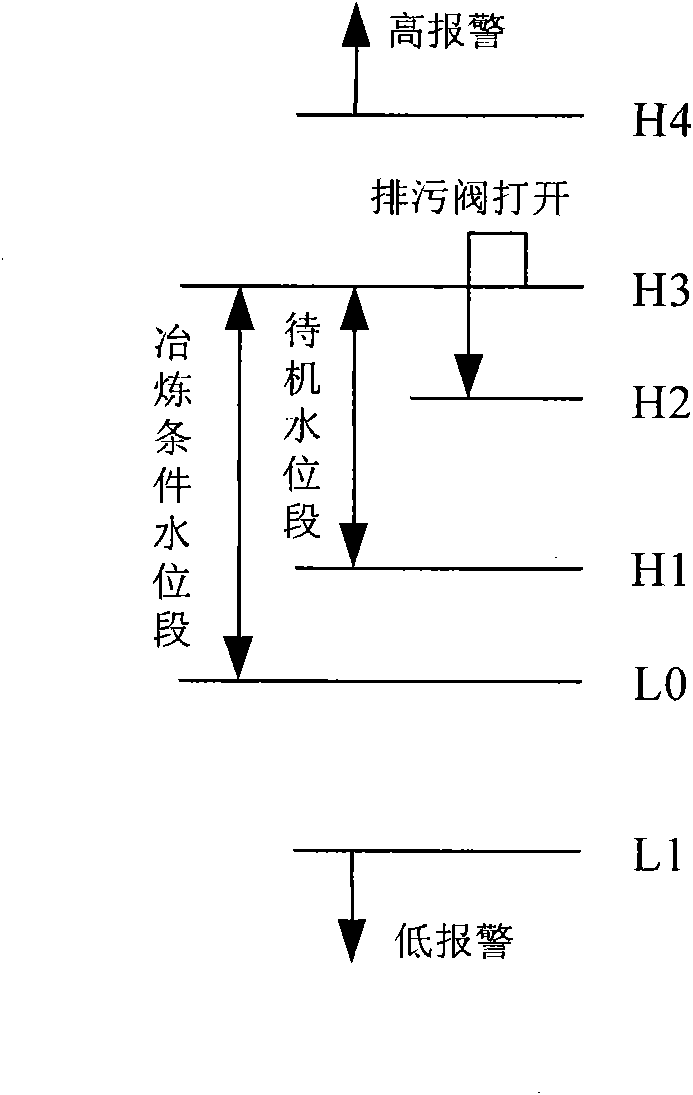

[0052] See figure 2 As shown, figure 2 Middle L actual Is the actual water level of the steam drum before the start of smelting, L0 is the lower limit water level of the steam drum that reaches the smelting condition, H3 is the upper limit water level of the steam drum that reaches the smelting condition, H2 is the stop water level of the drum, H1 is the standby lower limit water level, and H4 is the high alarm Water level, L1 is the low alarm water level.

[0053] See...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com