Method for producing methionine

A manufacturing method and technology of methionine, applied in chemical instruments and methods, preparation of organic compounds, preparation of sulfides, etc., can solve problems such as unimaginable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

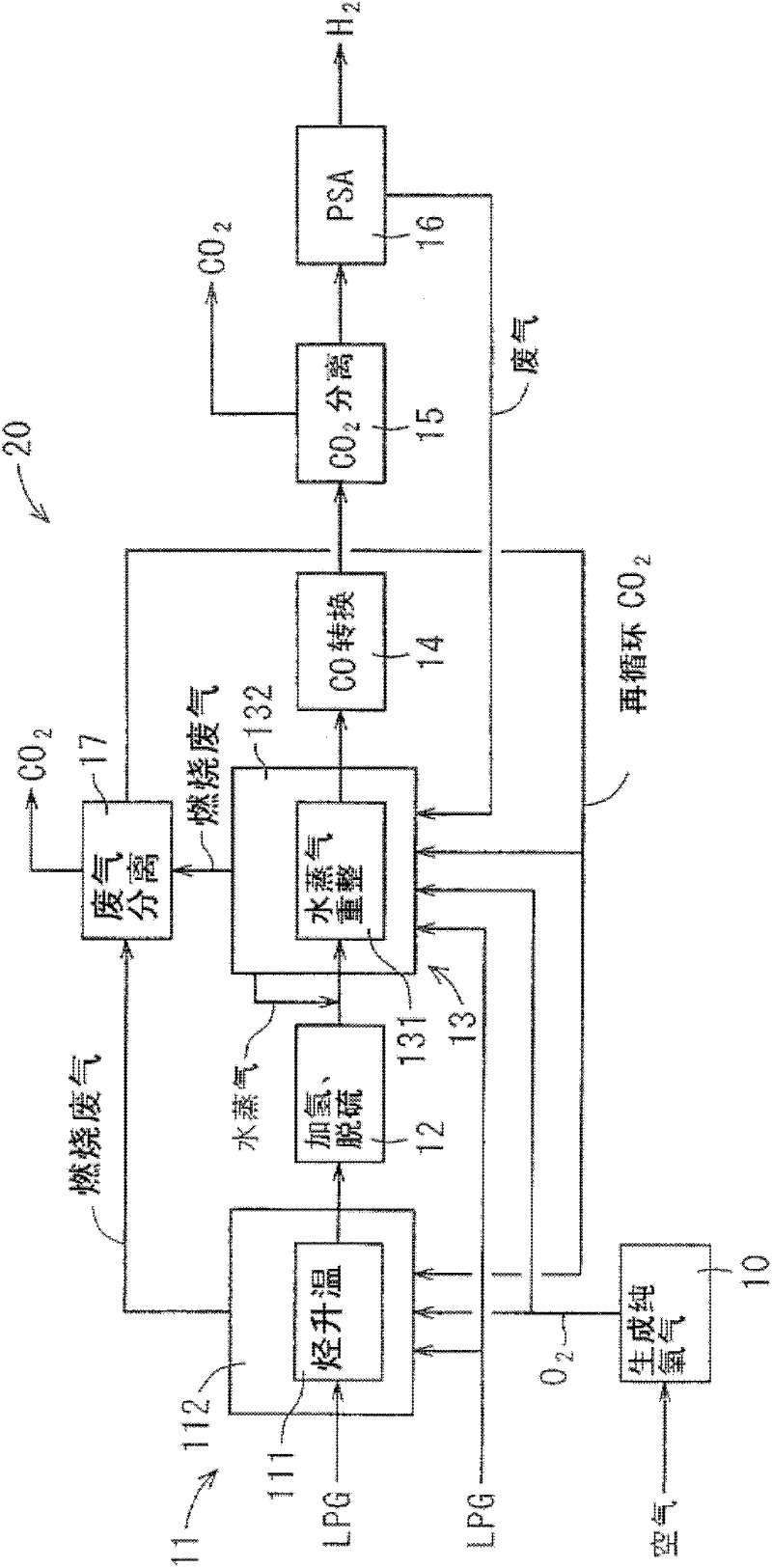

[0026] The best embodiment of the present invention will be described in detail with reference to the following drawings.

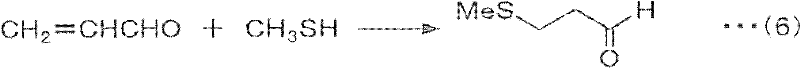

[0027] The method for producing methionine of the present invention is a method for producing methionine using hydrogen and carbon dioxide generated and recovered during hydrogen production, and includes a hydantoin step, a hydrolysis step, and a crystallization step. In addition, the hydantoin step includes a hydrogen sulfide step, a methylthiolation step, acroleinization step, a methylthiopropionylation step, a cyanohydrinization step, and a hydantoinization step.

[0028] In the hydrogen sulfide gas process, as shown in the following formula (1), hydrogen (H 2 ) react with sulfur (S) to give hydrogen sulfide (H 2 S). Hydrogen gas is used in this hydrogen sulfide step.

[0029] h 2 +S→H 2 S...(1)

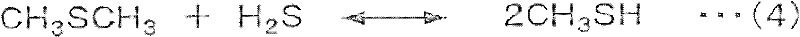

[0030] In the methyl mercaptan step, methyl mercaptan (CH 3 SH). It should be noted that CH in formulas (2), (3), and (4) 3 OH means methanol, CH 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com