Technology for preparing nitrogen trifluoride by gas-solid reaction direct fluorination method

A technology of nitrogen trifluoride and gas-solid reaction, which is applied in the direction of nitrogen and non-metallic compounds, can solve pollution and other problems, and achieve the effect of convenient use and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

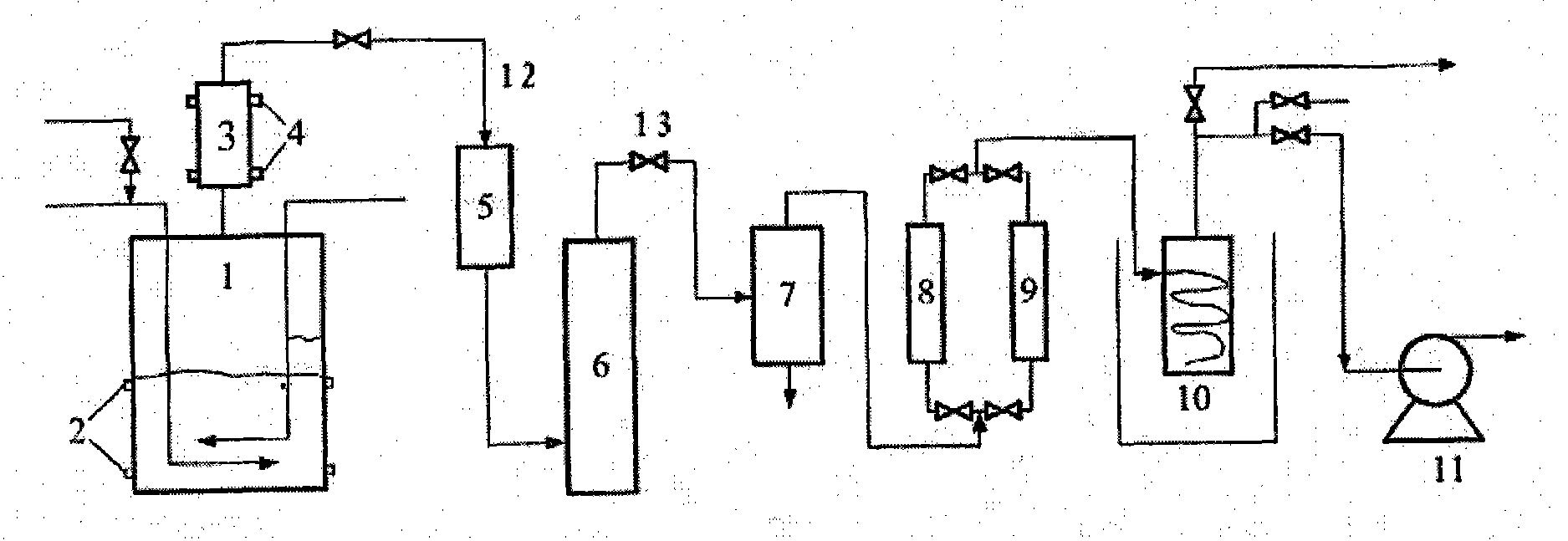

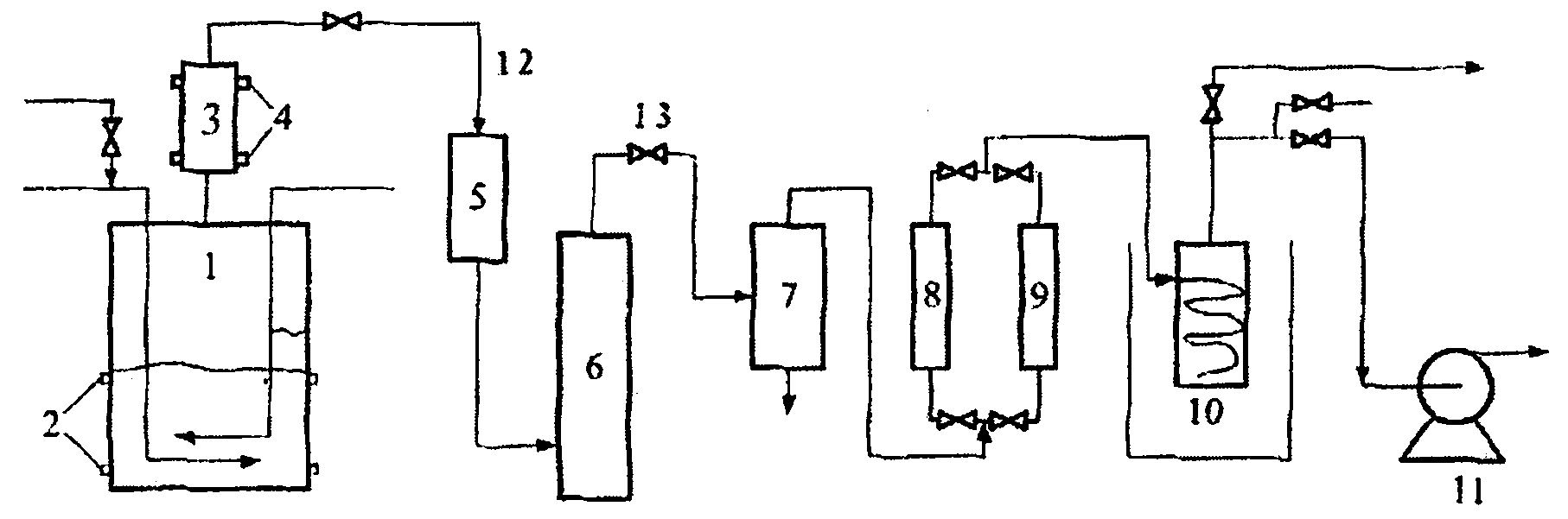

[0013] refer to figure 1 , Reactor 1 equipped with reactor heating device 2, demister 3 installed with demister heating device 4, trap 5, scrubber 6, cold trap 7, left adsorption column 8, right adsorption column 9, The condenser 10, the vacuum pump 11 and the connecting valve 13 are assembled into one body through the connecting pipeline 12 according to their system functions.

[0014] The present invention adopts the technology of direct fluorination of ammonia compound in perfluorocarbon liquid medium to prepare nitrogen trifluoride. The reactants are introduced into the reaction mixture and react at a temperature of 60-44°C to produce nitrogen trifluoride product. Perfluorocarbon fluids can improve the reaction between the fluorine reactant and the source of ammonium ions in various ways. The PFC in the reaction mixture at least partially dissolves the one or more sources of ammonium ions contained in the mixture. The fluorine reactant is also more readily soluble in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com