Sorting hanger lifting device

A spreader and sorting technology, used in transportation and packaging, cranes, walking bridge cranes, etc., can solve the problems of high manufacturing cost, unsafe use, inconvenient maintenance, etc., and achieve low cost and safety in later use. The effect of high coefficient and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

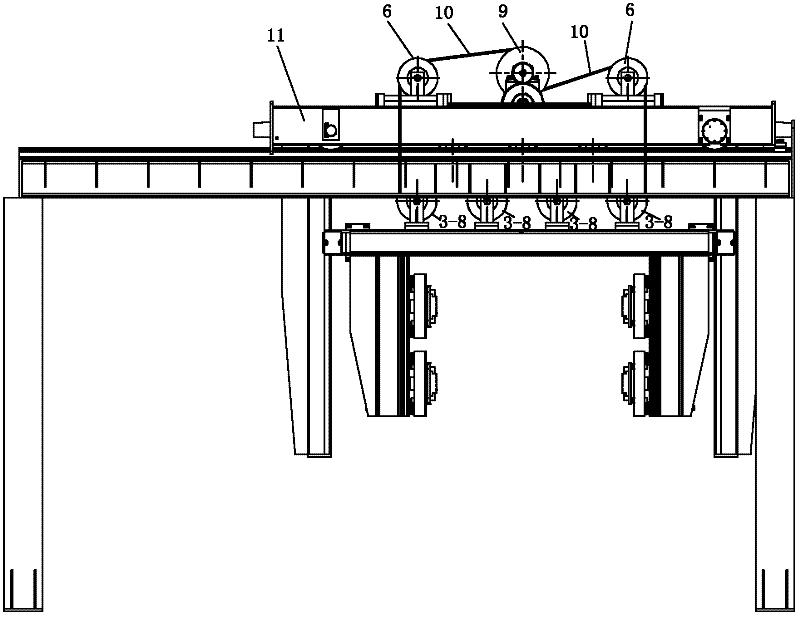

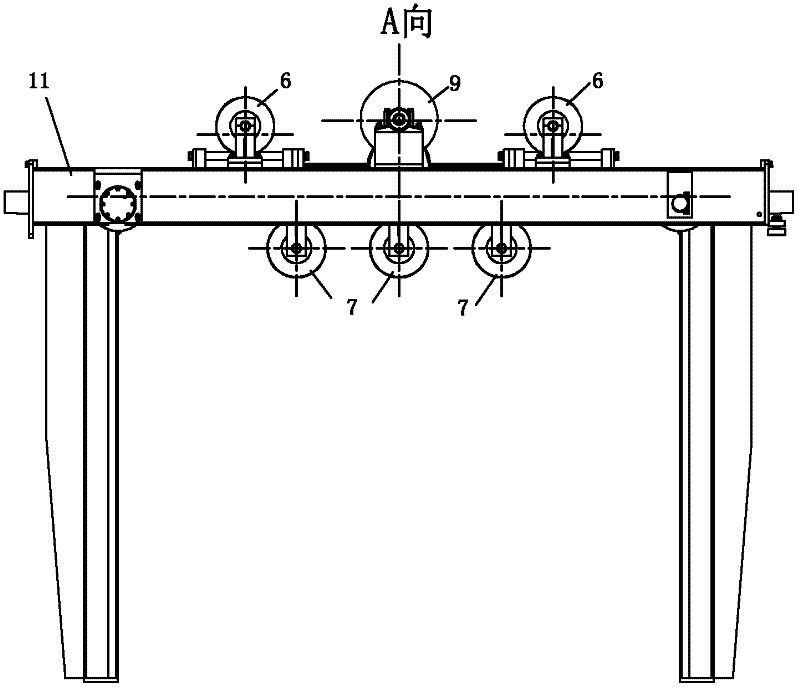

[0016] See figure 1 Turning to FIG. 7 , the illustrated embodiment has a walking frame 11 and a holding frame 12 .

[0017] The walking frame 11 is a frame structure, and the frame is provided with a center beam 11-1, a cylinder support frame 11-2 and a bearing bracket 11-3 fixed on the center beam 11-1.

[0018] Walking frame 11 top surfaces are provided with lifting shaft 4 and lifting cylinder 1, and lifting cylinder is 2, and wherein 1 is standby, can two work together when necessary, one pushes out, and one pulls. 2 lifting cylinders 1 are supported by cylinder support 11-2 respectively. Lifting shaft 4 is supported by two bearing blocks 5 . Two bearing housings 5 are supported by bearing housing brackets 11-3.

[0019] Described gear transmission mechanism comprises rack and pinion pair 2 and gear pair 3, and the rack 2-1 in the rack and pinion pair 2 is connected between 2 lifting cylinders 1, and the gear 3-2 in the rack and pinion pair 2 and The first gear 3-1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com