Suspension bed hydrogenation reactor with high pressure separator and process

A hydrogenation reaction and reactor technology, which is applied in the petroleum industry, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of coke-generated blockage and operation cycle of the device, reduce processing costs, simplify process flow, increase The effect of operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

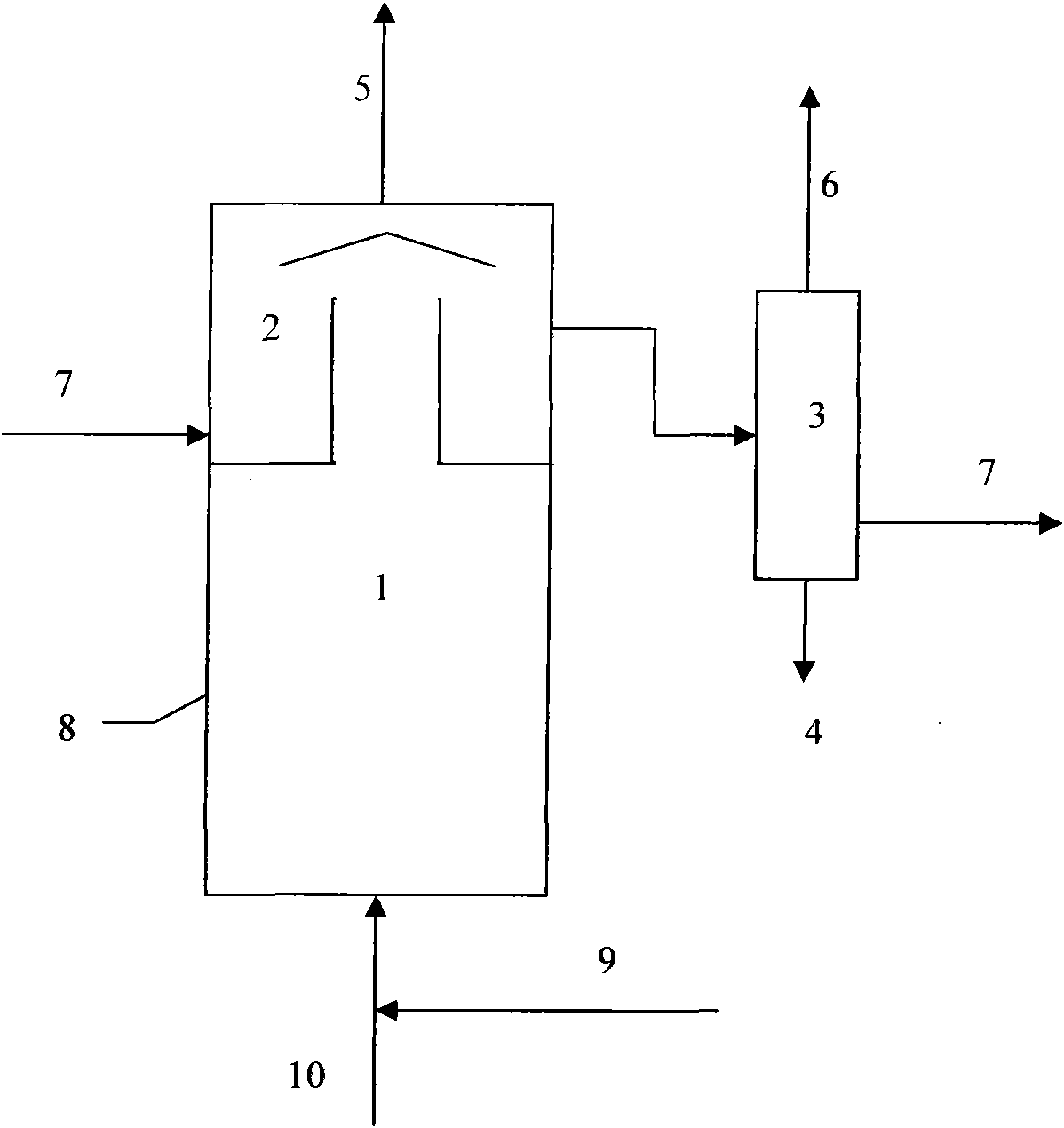

[0031] This example is an implementation of residual oil hydrotreating, and the schematic diagram of the operation process refers to the figure 1 .

[0032] The raw material oil 9 with the suspension bed hydrogenation catalyst is mixed with the hydrogen gas 5 and enters the suspension bed hydrogenation reaction zone 1 at the lower part of the suspension bed hydrogenation reactor 8 to carry out the suspension bed hydrogenation reaction. The material after the hydrogenation reaction passes upward through the chimney-like oil collector and enters the high-pressure stable separation zone 2. The stable diluent oil 7 rich in aromatics is used to cool down and dilute the material after the hydrogenation of the suspension bed to make it in a stable state. The stabilized liquid phase and the gas phase 5 undergo gas-liquid separation in the high-pressure stable separation zone, and then the liquid phase material enters the low-pressure separation and fractionation system 3 to separate l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com