Label dispensing device

A label and position shifting technology, which is applied in the field of label distribution devices, can solve problems such as difficult and efficient label distribution, and achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

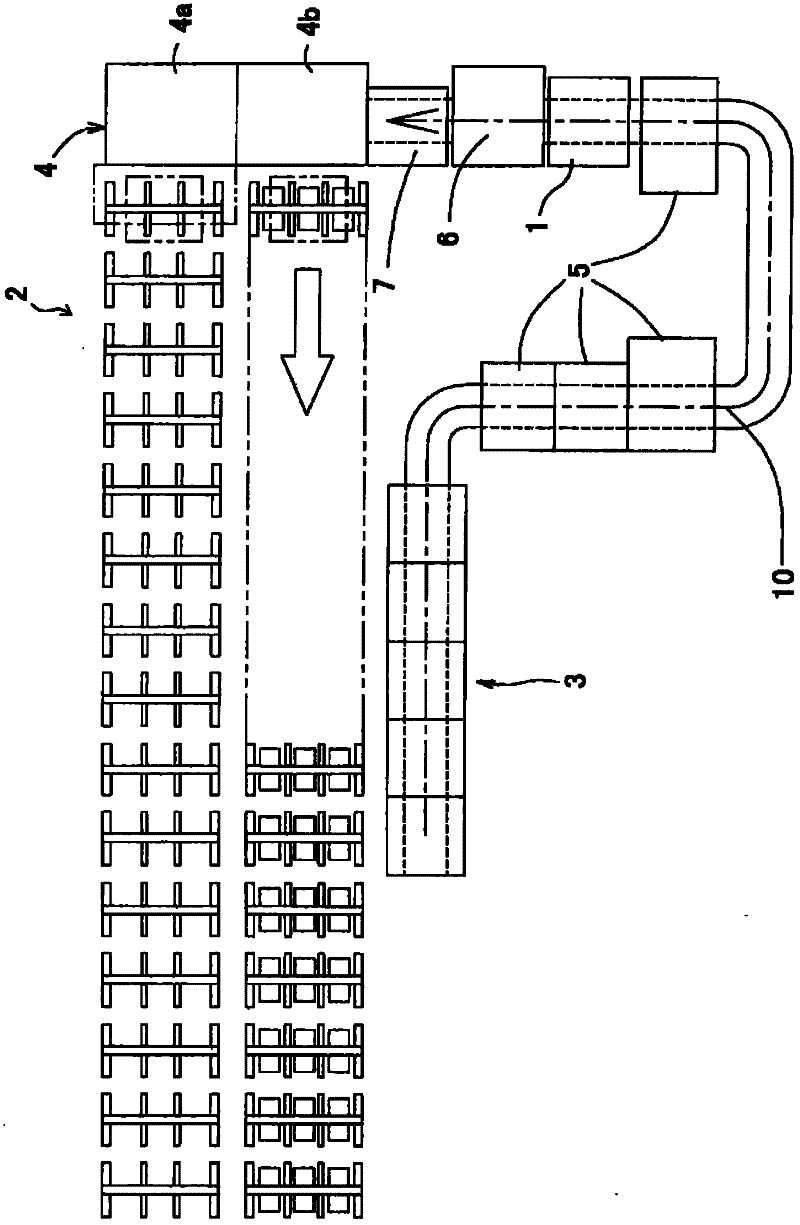

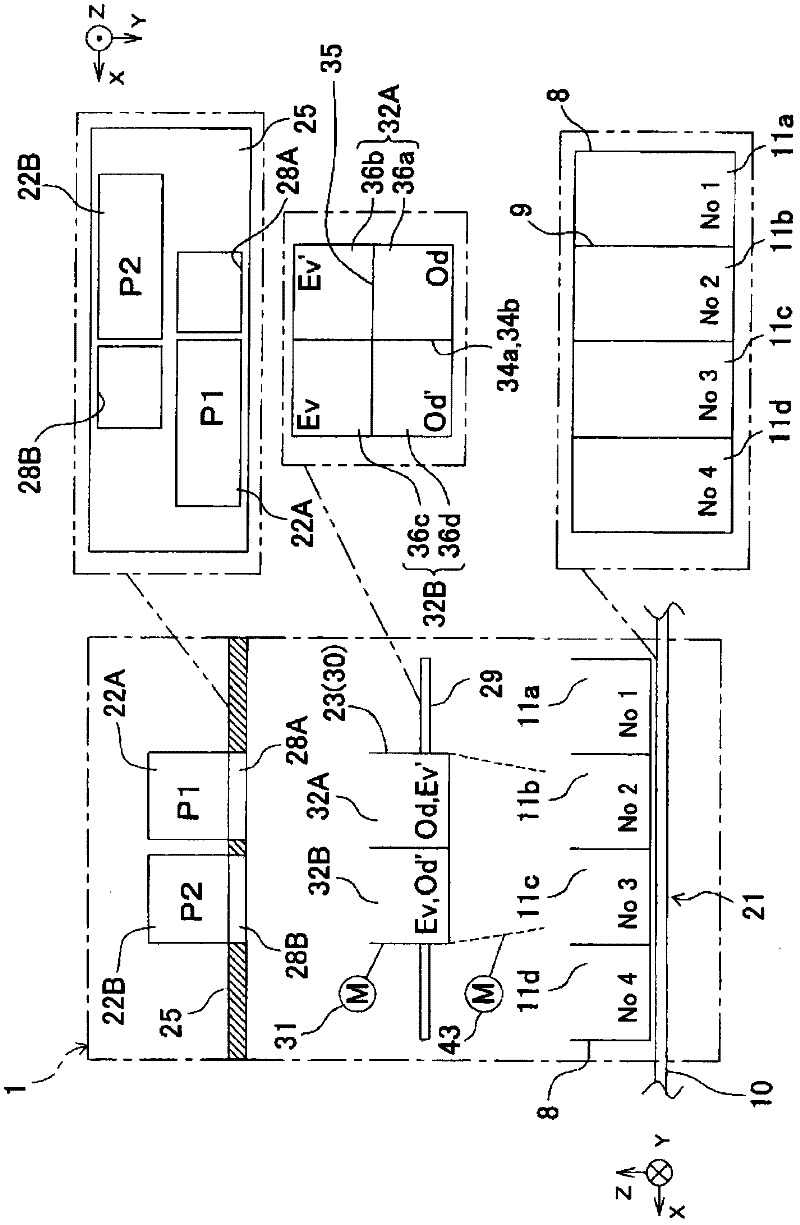

[0064] figure 1 A medicine supply system 2 including the label issuing device 1 according to the first embodiment of the present invention is shown. In the medicine supply system 2 , a plurality of medicine dispensing devices 5 , label dispensing devices 1 , card rewriting devices 6 , and stacker elevators 7 are arranged in the middle of a tray conveying line 10 connecting a medicine tray supply device 3 and a medicine tray discharge device 4 . The medicine tray 8 supplied by the medicine tray supply device 3 is conveyed on the tray conveying line 10 , passes through the medicine dispensing device 5 , the label dispensing device 1 , the card rewriting device 6 and the stacker elevator 7 in sequence, and then reaches the medicine tray discharge device 4 .

[0065] refer to Figure 6 The medicine tray 8 is a plastic container formed into a rectangular bottomed cylindrical shape in plan view, and a flange portion (jaw portion) 8 a is formed at the upper opening. In addition, gr...

no. 2 approach

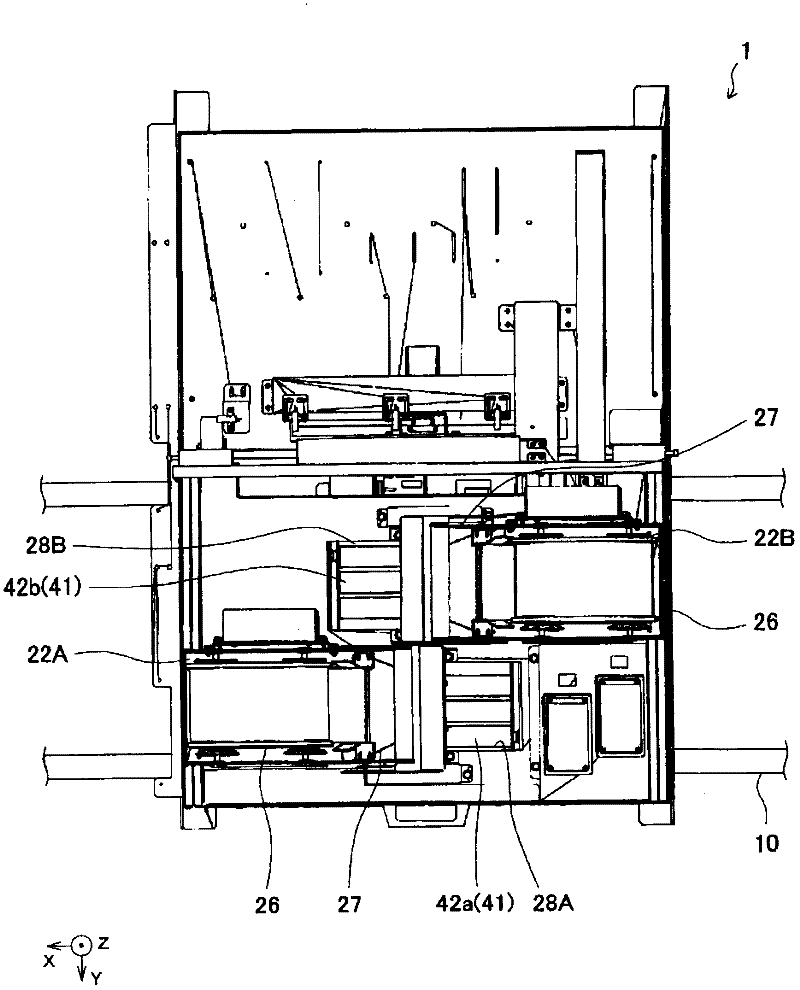

[0121] The label issuing device of the second embodiment is as Figure 15 and Figure 16 As shown, the configuration of the stacker 23 is different from that of the first embodiment. Other aspects and references of the label issuing device of the second embodiment Figure 1 ~ Figure 14H The label issuing device 1 of the first embodiment described is the same. exist Figure 15 and Figure 16 The same code|symbol is attached|subjected to the same element as 1st Embodiment among.

[0122] In this embodiment, the bottoms of the first and second label storage chambers 32A, 32B are formed, and labels L are placed on the upper surfaces respectively (see Figure 12A ~ Figure 14H ) are provided with openings 103A, 103B passing through the thickness direction on the shutter plates 42a, 42b. In addition, if Figure 17 and Figure 18 As shown most clearly, three elongated strip-shaped adsorption prevention plates 101 are attached to the upper surfaces of the gates 42a, 42b for eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com