Preparation method of lithium-ion battery cathode material wet-coated aluminum

A technology for lithium-ion batteries and cathode materials, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor high-temperature safety performance and high-temperature cycle performance, difficult control of electrochemical performance, and difficulty in uniform mixing, etc., to achieve Good high temperature safety and cycle characteristics, easy coating process conditions, and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] NiSO 4 、CoSO 4 , MnSO 4 Moore than Ni 2+ :CO 2+ :Mn 2+ = Mix in a ratio of 5:2:3, dissolve in deionized water, and make a solution with a comprehensive ion concentration of 2mol / L. Prepare 4mol / L sodium hydroxide solution, and add NH in the sodium hydroxide solution 3 ·H 2 O: ammonia water with NaOH=0.2. Put the two mixed solutions into the reaction kettle in parallel, and under the protection of nitrogen or rare gas, the reaction is controlled in a continuous reaction mode, the pH value is controlled between 10-12, and the temperature is 50-60°C. After the reaction is completed, filter and wash to The pH value of the washing water is less than 8, and it is dried at 110°C to obtain Ni 0.5 co 0.2 mn 0.3 (OH) 2 Precursor.

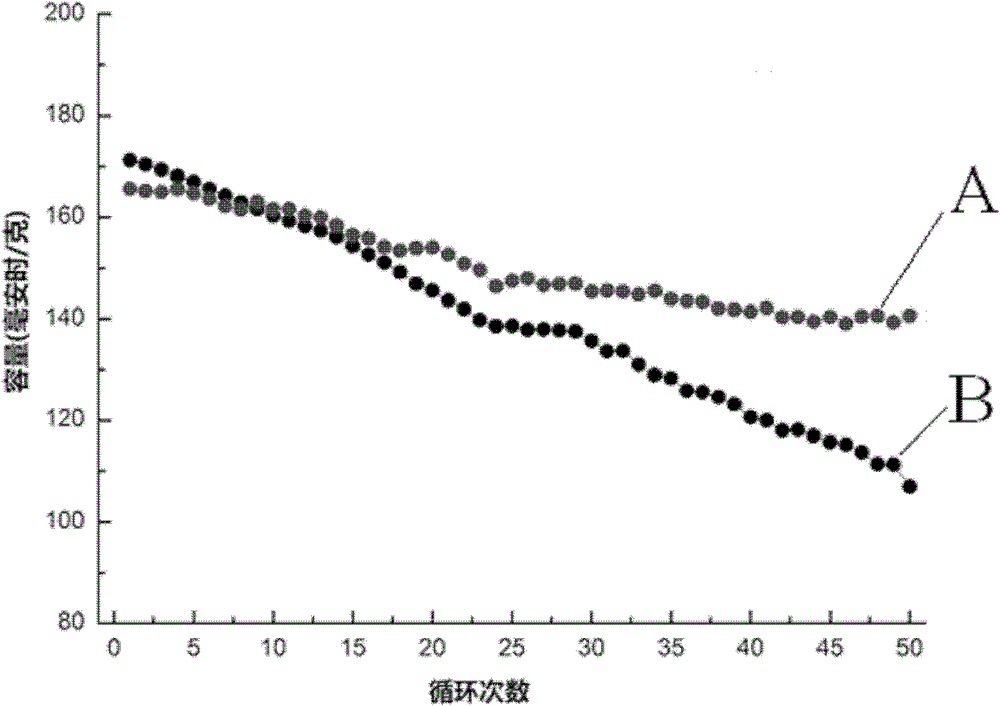

[0034] Dissolve aluminum isopropoxide in isopropanol to prepare a 30 g / L solution of aluminum isopropoxide in isopropanol. The coating amount of the designed material is 0.02mol (Al / (Ni+Co+Mn)), and the two solutions are mixed and added wi...

Embodiment 2

[0044] NiCl 2 、CoCl 2 , MnCl 2 Moore than Ni 2+ :CO 2+ :Mn 2+ = Mix in the ratio of 70:15:15, dissolve with deionized water, and make a solution with a comprehensive ion concentration of 2mol / L. Prepare 4mol / L sodium hydroxide solution, and add NH in the sodium hydroxide solution 3 ·H 2 O: ammonia water with NaOH=0.2. Add the two mixed solutions into the reaction kettle in parallel, react under the protection of nitrogen, control the pH value between 10-12, and the temperature is 50-60°C, filter and wash until the pH value of the washing water is less than 8, and dry at 120°C. Get Ni 0.70 co 0.15 mn 0.15 (OH) 2 Precursor.

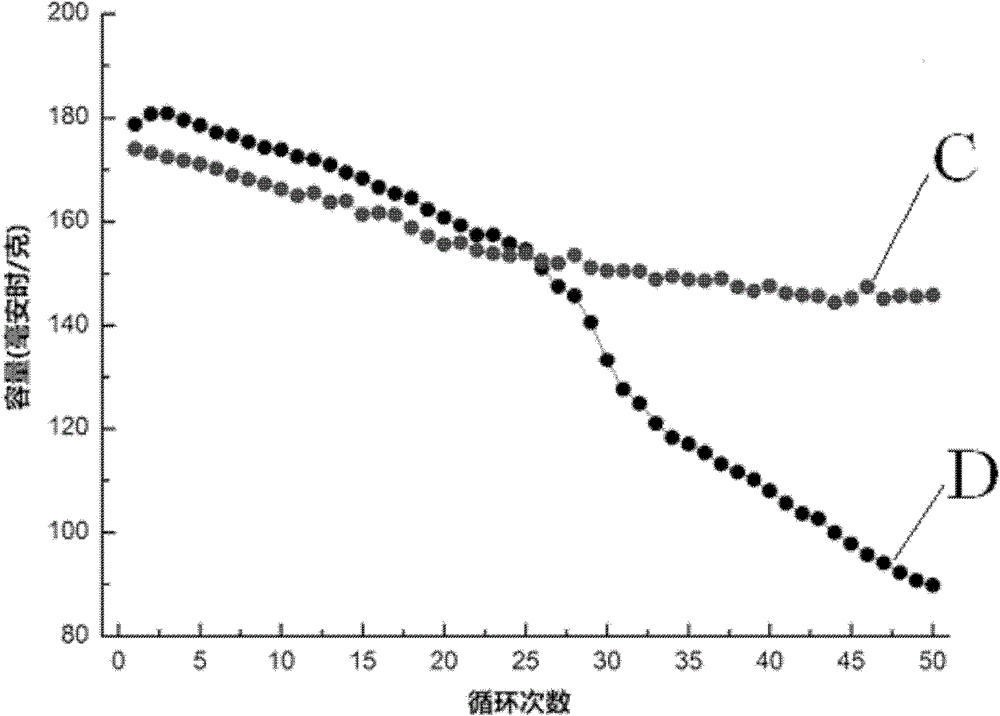

[0045] Dissolve aluminum isopropoxide in isopropanol to prepare a 100 g / L solution of aluminum isopropoxide in isopropanol. The coating amount of the designed material is 0.02mol (Al / (Ni+Co+Mn)), and the two solutions are mixed and added with a solid content of 40% Ni 0.7 co 0.15 mn 0.15 (OH) 2 In the precursor solution, the temperature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com