Triaxial integrated all-optical-fiber inertial sensing system

An inertial sensing and all-fiber technology, applied in the field of inertial sensing, can solve the problems of increased redundant design, large noise interference, and poor stability, and achieve the effects of improving stability and reliability, avoiding cross-coupling, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Further illustrate the present invention below in conjunction with accompanying drawing.

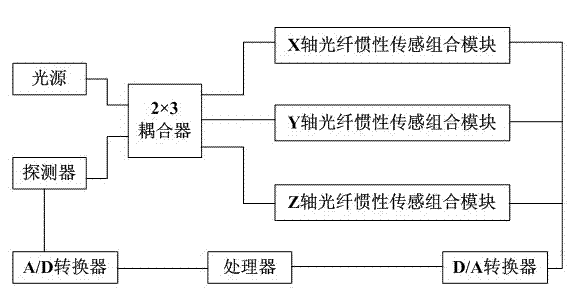

[0012] Such as figure 1 As shown, the three-axis integrated all-fiber inertial sensing system includes: light source, 2×3 coupler, X-axis fiber optic inertial sensing combination module, Y-axis fiber optic inertial sensing combination module, Z-axis fiber optic inertial sensing combination module, detection device, A / D converter, processor and D / A converter; among them, one end of the 2×3 coupler is respectively connected to the input end of the light source and the detector, and the other end is respectively connected to the X-axis optical fiber inertial sensing combination module, The Y-axis fiber optic inertial sensing combination module is connected to the Z-axis fiber optic inertial sensing combination module; the detector is connected to the processor through the A / D converter, and the processor is respectively connected to the X-axis fiber optic inertial sensing combination...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com