Gasoline engine and air valve rocker assembly for same

A gasoline engine and valve technology, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problems that the force of the valve is inconsistent with the direction of operation, affects the normal operation of the gasoline engine, and affects the sealing effect, etc., and achieves a small amount of movement or sloshing , high strength, and the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

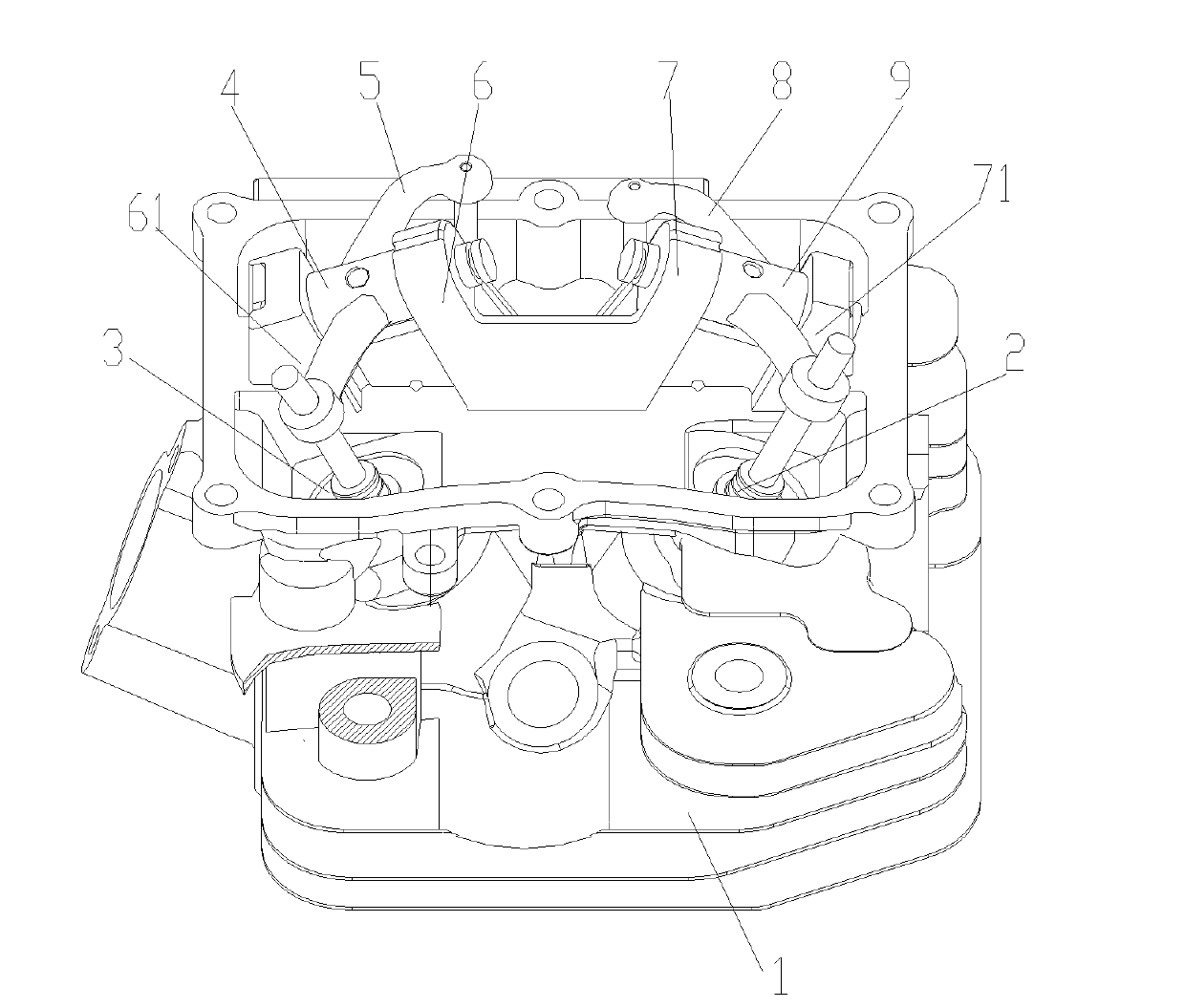

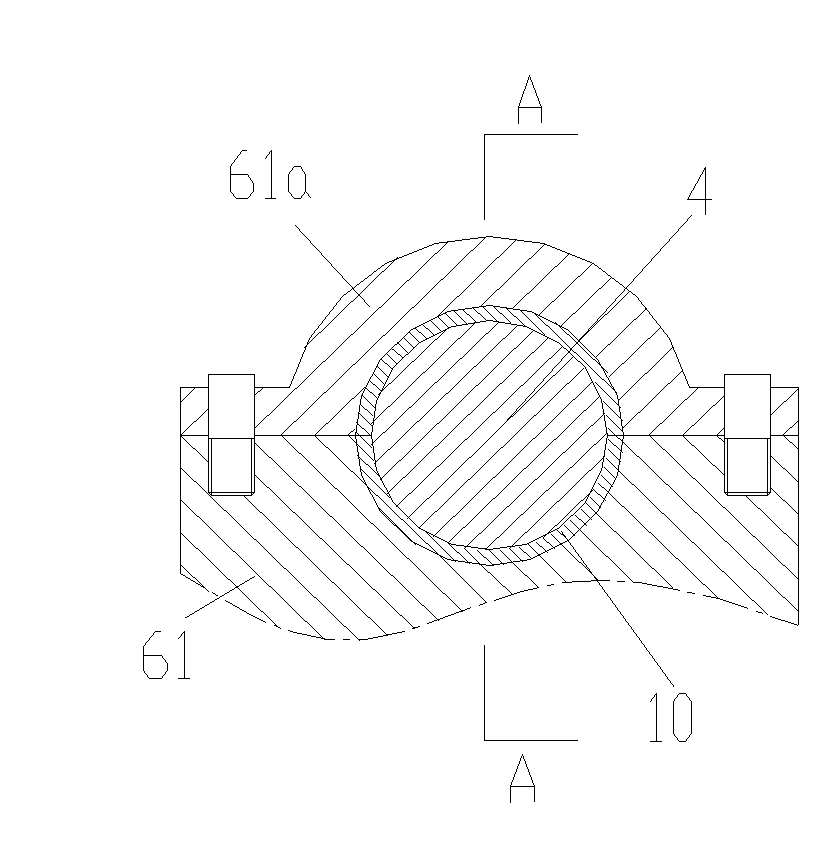

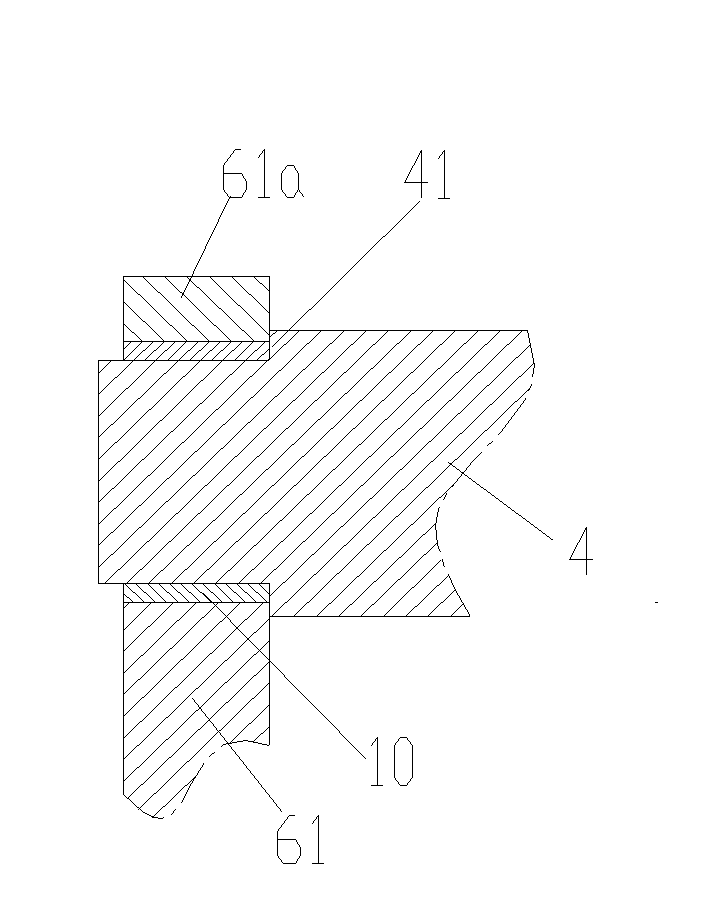

[0022] figure 1 It is a structural schematic diagram of the present invention, as shown in the figure: the gasoline engine valve driving device of the present embodiment includes an intake valve rocker arm 5, an exhaust valve rocker arm 8, an intake valve rocker arm seat 6 and an exhaust valve rocker arm seat 7. The intake valve rocker arm 5 is fixedly provided with an intake valve rocker arm shaft 4, and the intake valve rocker arm shaft 4 is arranged on the intake valve rocker arm seat 6 with a single degree of freedom in a manner that can rotate around its own axis The exhaust valve rocker arm 8 is fixedly provided with an exhaust valve rocker arm shaft 9, and the exhaust valve rocker arm shaft 9 is arranged on the exhaust valve rocker arm seat 7 with a single degree of freedom in a manner that can rotate around its own axis;

[0023] The intake valve rocker shaft 4 and the exhaust valve rocker shaft 9 are arranged radially inward relative to the top of the cylinder head in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com