Blue alga cake tubular pyrohydrolysis dewatering method and device

A technology of cyanobacteria cake and thermal hydrolysis, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of large-scale production difficulty, harsh equipment requirements, multi-processing processes, etc., to achieve easy large-scale treatment, continuous and stable Operation, the effect of reducing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

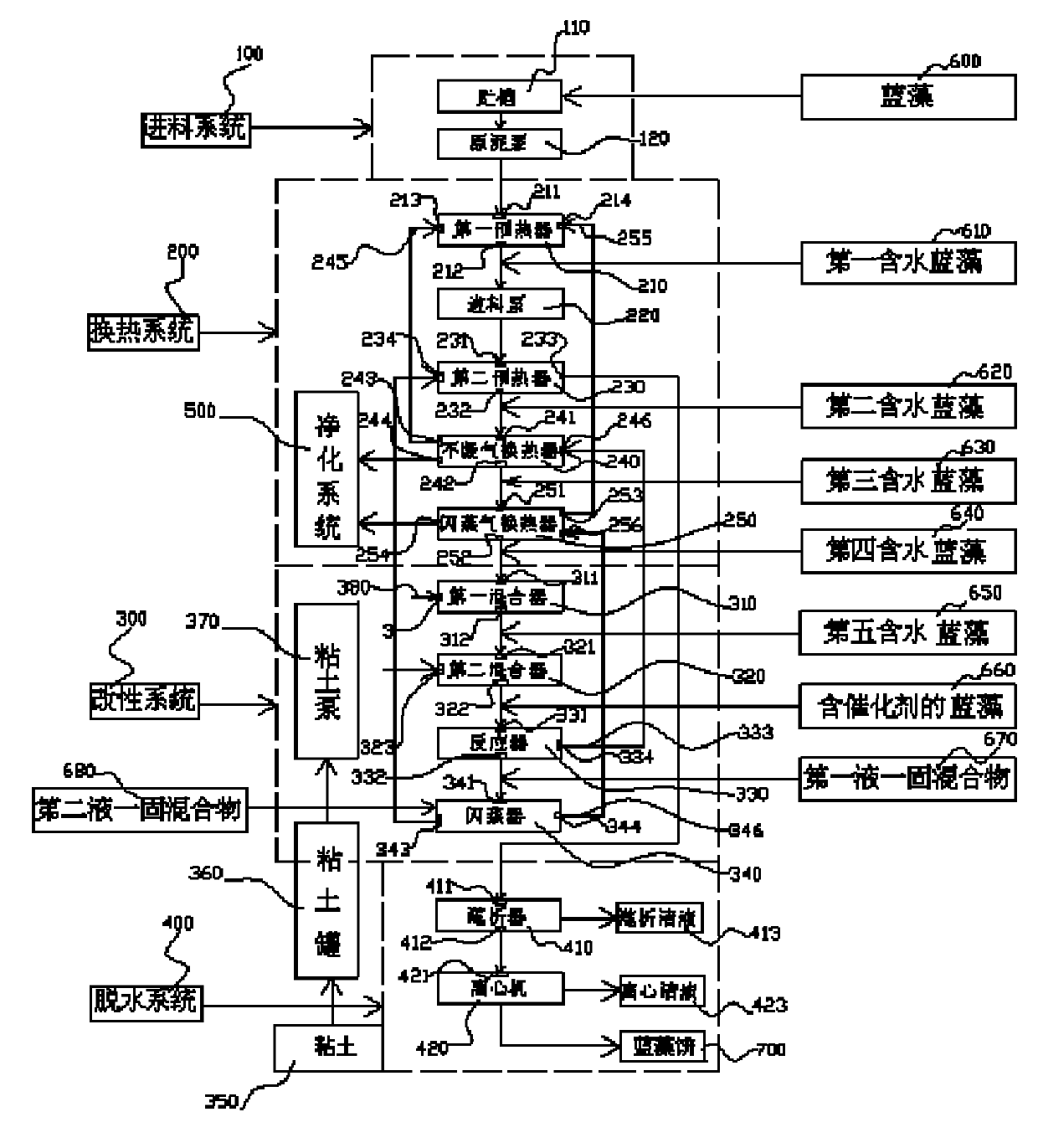

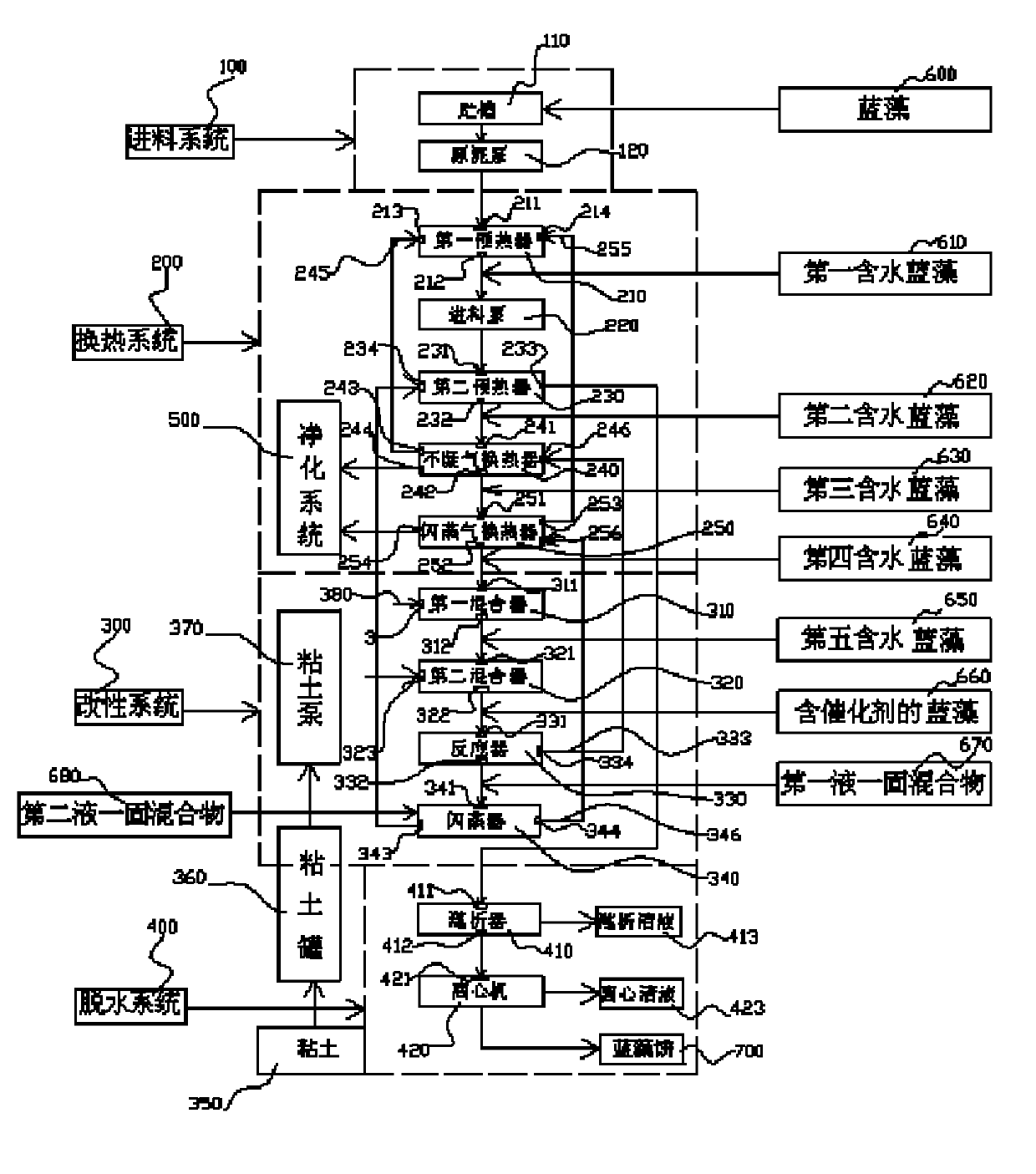

[0047] A kind of cyanobacteria tube type thermal hydrolysis processing method, comprises the following steps, as figure 1 Shown:

[0048] (1), preheating pressure test steps:

[0049] Use steam to preheat and pressure test the tubular cyanobacteria cake processing device. The pressure test standard: the pressure of the modification system is 0.1-0.8Mpa, and the pressure of the four systems of dehydration system, heat exchange system, feed system and purification system is 0.1 -0.3Mpa, the whole preheating pressure test process stops when the temperature of the tubular cyanobacteria treatment device reaches 120-150°C;

[0050] (2), the first preheating step:

[0051] Use the raw material pump 120 to continuously send the cyanobacteria 600 from the storage tank 110 to the preheater 210 in the heat exchange system 100, and exchange the liquid 245 and flash steam with the non-condensable gas heat exchanger 240 in the heat exchange system 200. The liquid 255 sent by the heater 2...

Embodiment 2

[0077] see again figure 1 , a cyanobacteria tubular thermal hydrolysis treatment method, comprising the following steps:

[0078] (1), preheating pressure test steps:

[0079] Use steam to preheat and pressure test the tubular cyanobacteria cake processing device. The pressure test standard: the pressure of the modification system is 0.1-0.8Mpa, and the pressure of the four systems of dehydration system, heat exchange system, feed system and purification system is 0.1 -0.3Mpa, the whole preheating pressure test process stops when the temperature of the tubular cyanobacteria treatment device reaches 120-150°C;

[0080] (2), the first preheating step:

[0081] Use the raw material pump 120 to continuously send the cyanobacteria 600 from the storage tank 110 to the preheater 210 in the heat exchange system 100, and send the first liquid 245 and the flash gas to the non-condensable gas heat exchanger 240 in the heat exchange system 200. The second liquid 255 sent from the steam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com