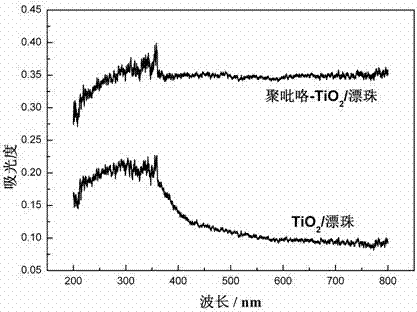

Floating polypyrrole-TiO2/floating bead photocatalyst, and preparation method and application thereof

A catalyst, polypyrrole technology, used in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, chemical instruments and methods, etc., can solve the problems of difficulty in recycling, waste of resources, etc. , easy to recycle, improve the effect of photocatalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Pretreatment of floating beads: Soak the floating beads extracted from fly ash with dilute nitric acid for 8 hours, then rinse with distilled water until the outflowing water is neutral, and dry them for later use;

[0024] 2) Using butyl titanate, absolute ethanol, acetylacetone, and ultrapure water as raw materials, the molar ratio of butyl titanate, absolute ethanol, acetylacetone, and ultrapure water is 1:26:1:1. Adjust the pH to 5 with concentrated nitric acid, stir to make it fully react, then add polyethylene glycol so that the molar ratio of butyl titanate to polyethylene glycol is 1000:1, heat and stir to fully dissolve it, and then obtain yellow Transparent TiO 2 Sol;

[0025] 3) To TiO 2 Add the pretreated floating bead carrier in step 1) to the sol, so that the mass ratio of butyl titanate to floating beads is 7:1, stir to mix evenly, and after immersing for 24 h, filter off the excess sol, and filter out The sample was dried, then placed in a muffle f...

Embodiment 2

[0038] 1) Fly ash floating bead pretreatment: Soak in 10% by weight dilute nitric acid for 8 hours, rinse with a large amount of distilled water until the outflowing water is neutral, and dry it for later use.

[0039] 2) Using butyl titanate, absolute ethanol, acetylacetone, and ultrapure water as raw materials, the molar ratio of butyl titanate, absolute ethanol, acetylacetone, and ultrapure water is 1:26:1:1. Adjust the pH to 5 with concentrated nitric acid, stir to make it fully react, then add polyethylene glycol so that the molar ratio of butyl titanate to polyethylene glycol is 1000:1, heat and stir to fully dissolve it, and then obtain yellow Transparent TiO 2 Sol;

[0040] 3) To TiO 2 Add the pretreated floating bead carrier in step 1) to the sol, so that the mass ratio of butyl titanate to floating beads is 7:1, stir to mix evenly, and after immersing for 24 h, filter off the excess sol, and filter out The sample was dried, then placed in a muffle furnace for calc...

Embodiment 3

[0049] 1) Fly ash floating bead pretreatment: Soak in 10% by weight dilute nitric acid for 8 hours, rinse with a large amount of distilled water until the outflowing water is neutral, and dry it for later use.

[0050] 2) Using butyl titanate, absolute ethanol, acetylacetone, and ultrapure water as raw materials, the molar ratio of butyl titanate, absolute ethanol, acetylacetone, and ultrapure water is 1:26:1:1. Adjust the pH to 5 with concentrated nitric acid, stir to make it fully react, then add polyethylene glycol so that the molar ratio of butyl titanate to polyethylene glycol is 1000:1, heat and stir to fully dissolve it, and then obtain yellow Transparent TiO 2 Sol;

[0051] 3) To TiO 2 Add the pretreated floating bead carrier in step 1) to the sol, so that the mass ratio of butyl titanate to floating beads is 7:1, stir to mix evenly, and after immersing for 24 h, filter off the excess sol, and filter out The sample was dried, then placed in a muffle furnace for calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com