Sole with drainage fan blades

A technology for fan blades and shoe soles, which is applied to shoe soles, footwear, applications, etc. It can solve the problems of difficult drainage and poor slip resistance of shoe soles, and achieve the effects of accelerating fluidity, improving adhesion, and increasing friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

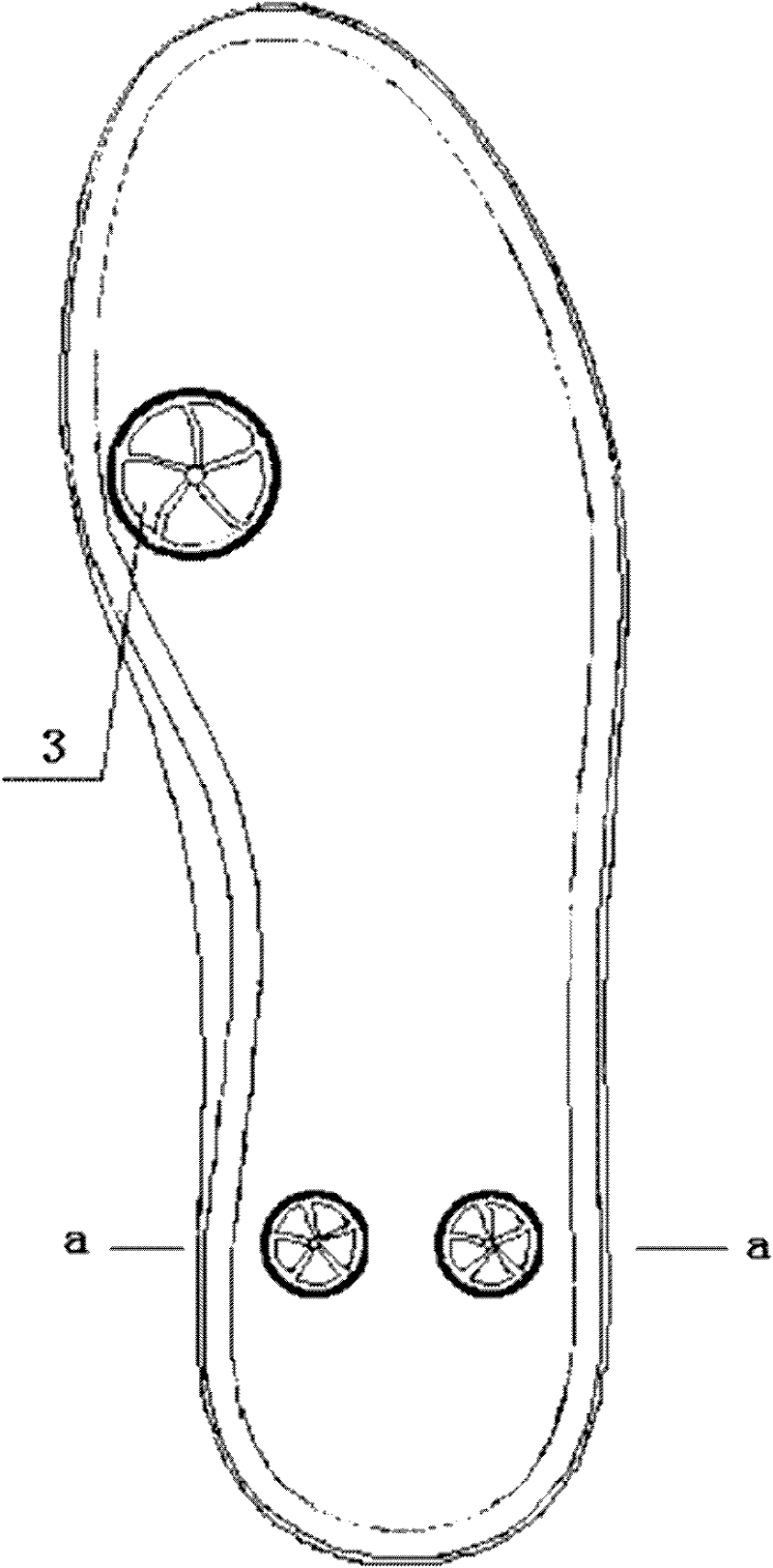

[0025] Depend on figure 1 As shown, there are three grooves 1 distributed sequentially from the toe to the heel on the bottom surface of the sole of the present embodiment, figure 1 The groove in the groove is circular, and of course it can also be elliptical or other special-shaped. The center of the bottom surface of each groove 1 is provided with five spirally distributed fan blades 3 that radiate outward. figure 1 There is only one layer of fan blades 3, of course it can be two or more layers of fan blades 3 spirally distributed, there are gaps 4 between the fan blades 3, each fan blade 3 is a petal-shaped structure, and each fan blade 3 adjacent The slits 4 are formed between the inner edges, and each slit 4 has the same bending direction, forming the spiral distribution; the outer edge of each fan blade 3 forms a circular edge. Depend on image 3 which is figure 1 As shown in the sectional view of the a-a section in the middle, the fan blade 3 forms a hollow ball tabl...

Embodiment 2

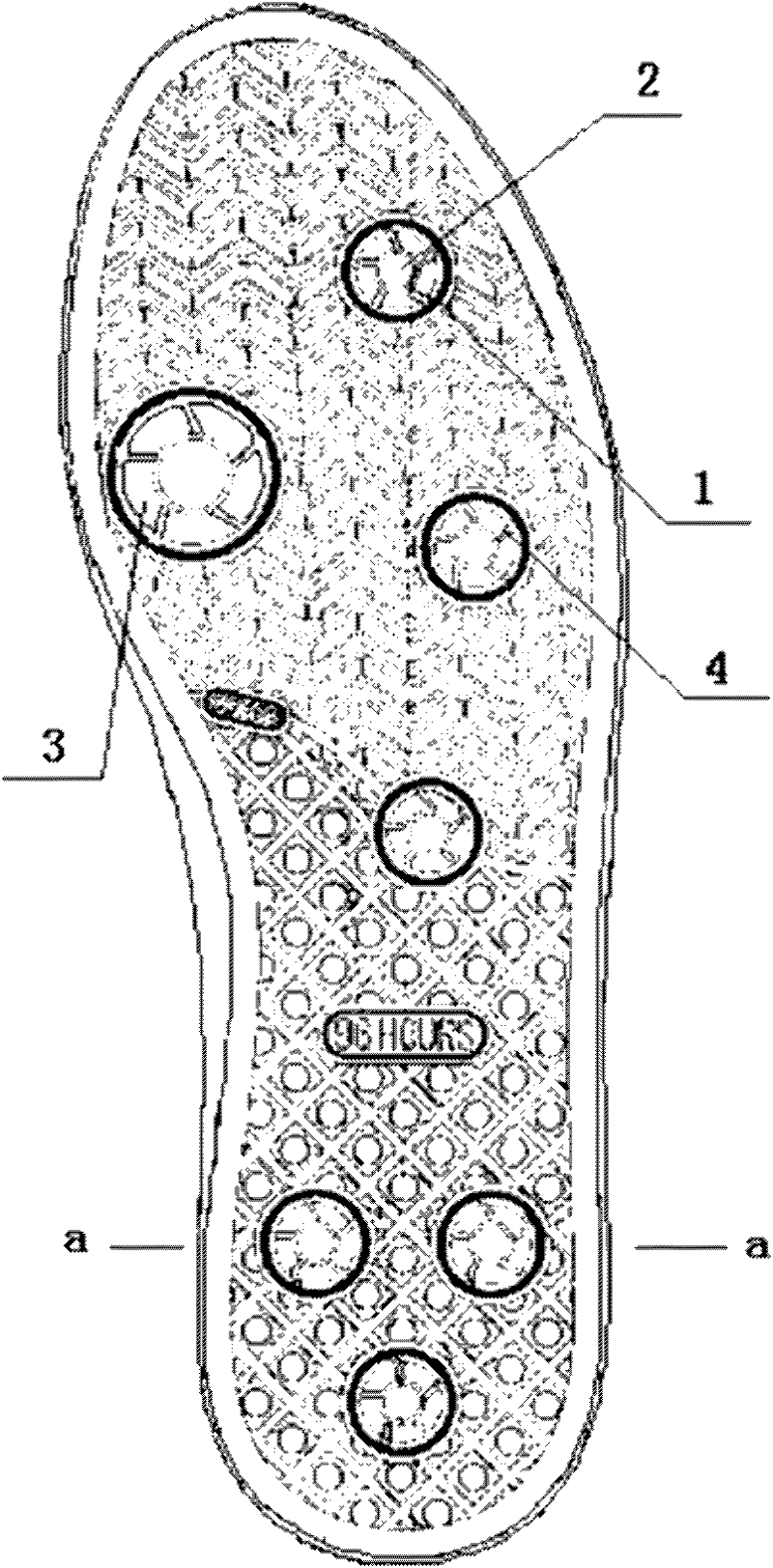

[0028] Depend on figure 2 As shown, seven circular grooves 1 are distributed sequentially from the toe of the shoe to the bottom of the heel in this embodiment, and each groove 1 has a circular protrusion 2 in the center, so that water will not accumulate in the center. Five spiral fan blades 3 radiate outward, and the inner surface of each fan blade 3 is bent inward to form a concave structure, and gaps 4 are left between the fan blades 3 . Depend on Figure 4 which is figure 2 As shown in the sectional view of the a-a section in the middle, the fan blade 3 forms a hollow ball table as a whole and the outer edge protrudes from the bottom surface of the sole, and the diameter of the outer edge of the fan blade 3 is slightly smaller than the diameter of the groove 1 . There are also non-slip and decorative textures on the sole surface. When the user wears the shoes and walks on the ground with a lot of water, the water enters the groove 1 and is squeezed between the shoes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com