Auto generator stator core winding body

A technology for automotive generators and stator cores, applied in the manufacture of stator/rotor bodies, etc., can solve problems such as difficult winding, difficult mass production, and unstable winding operation, and achieve stable winding operation and good product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

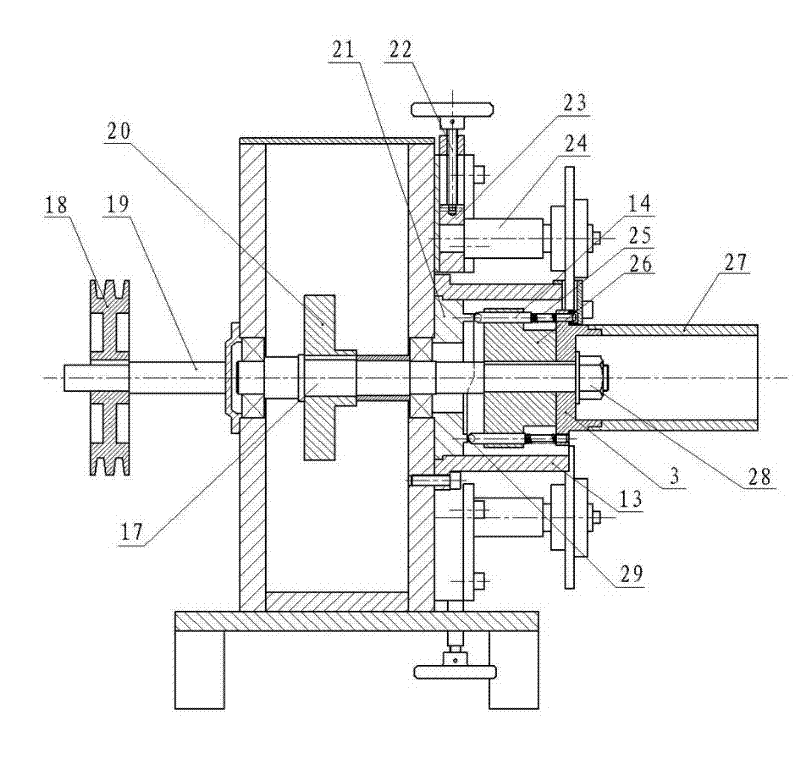

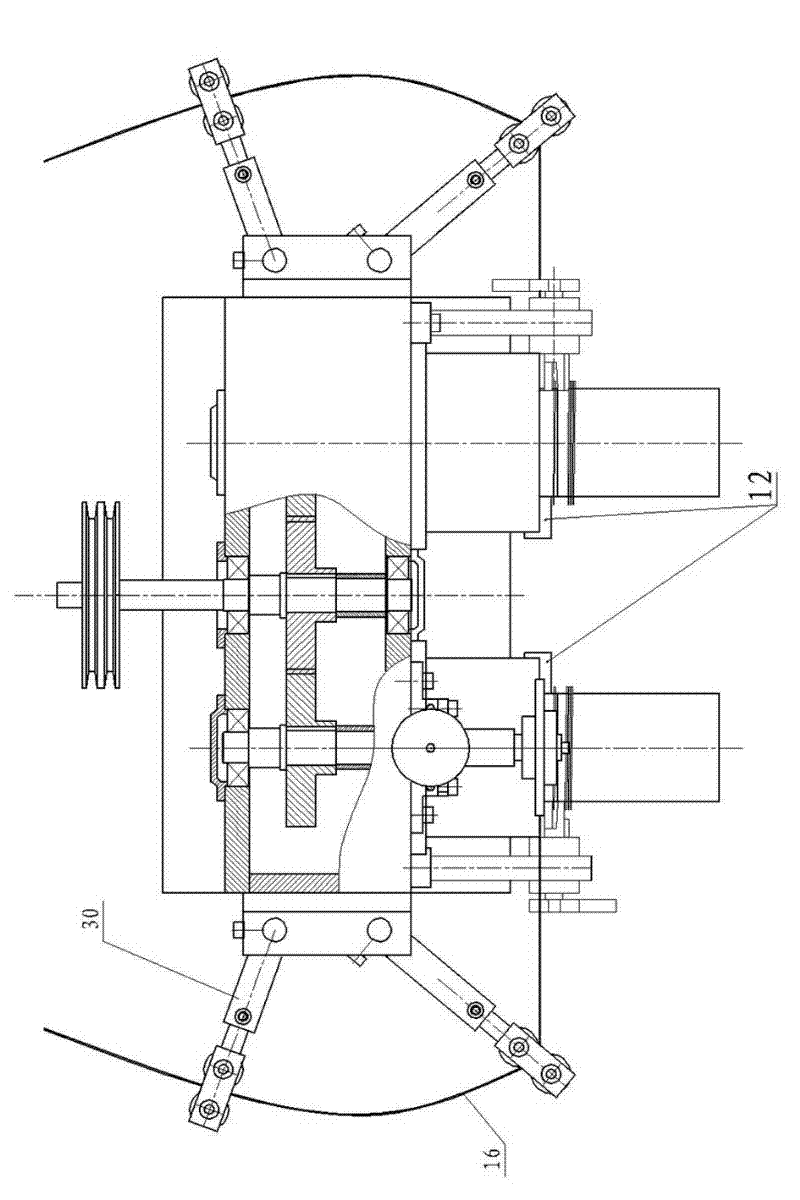

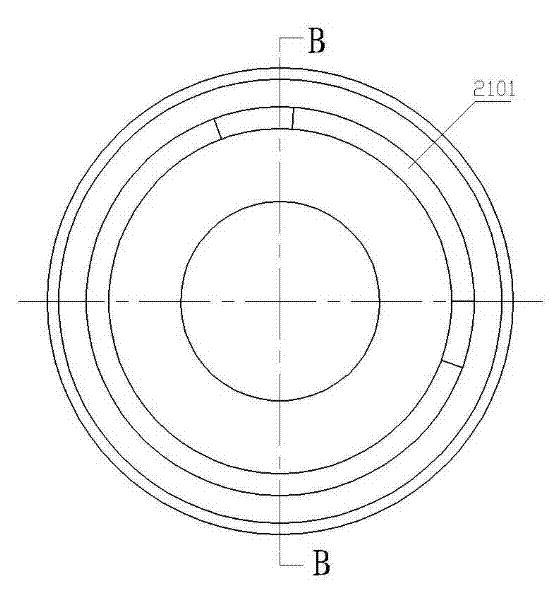

[0026] The automobile generator stator core winding machine body involved in the present invention includes a machine base 1 and a box body 2 fixed on the machine base 1, and a group of nearly tangential pressing wheels 10 and winding wheels 3 are respectively arranged on both sides of the front of the box body 2. , the pressure wheel 10 on the left is above the winding wheel 3 , and the pressure wheel 10 on the right is below the winding wheel 3 . A transmission shaft 19 and two winding wheel shafts 17 are installed in parallel through bearings in the box body 2, and the two winding wheel shafts 17 are symmetrically arranged on both sides of the transmission shaft 19 and are respectively connected with the transmission shaft 19 through a gear or a chain transmission mechanism. In this embodiment, the gear transmission mechanism 20 is taken as an example. The passive gears on the two winding axles 17 are of the same size and mesh with the driving gear on the transmission shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com