A kind of preparation method of lithium iron phosphate positive electrode material of lithium ion battery

A technology for lithium-ion batteries and lithium iron phosphate, which is applied in the field of preparation of lithium-ion battery materials, can solve problems such as uneven dispersion of conductive agents and affect the conductivity of positive active materials, achieve excellent conductivity, improve utilization efficiency, and increase accumulation effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

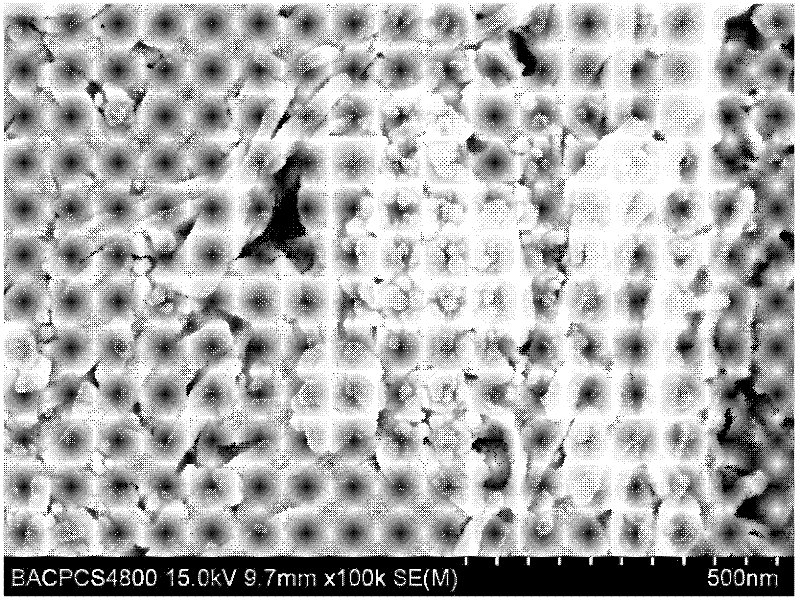

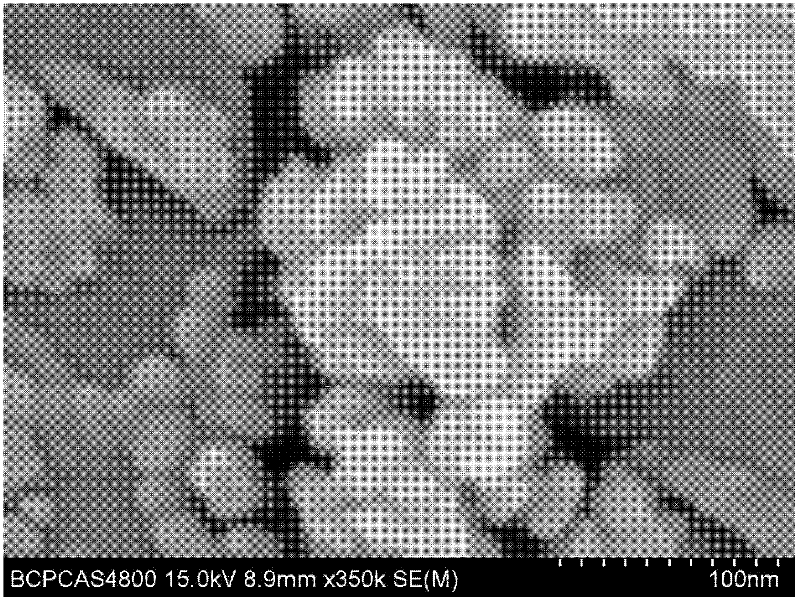

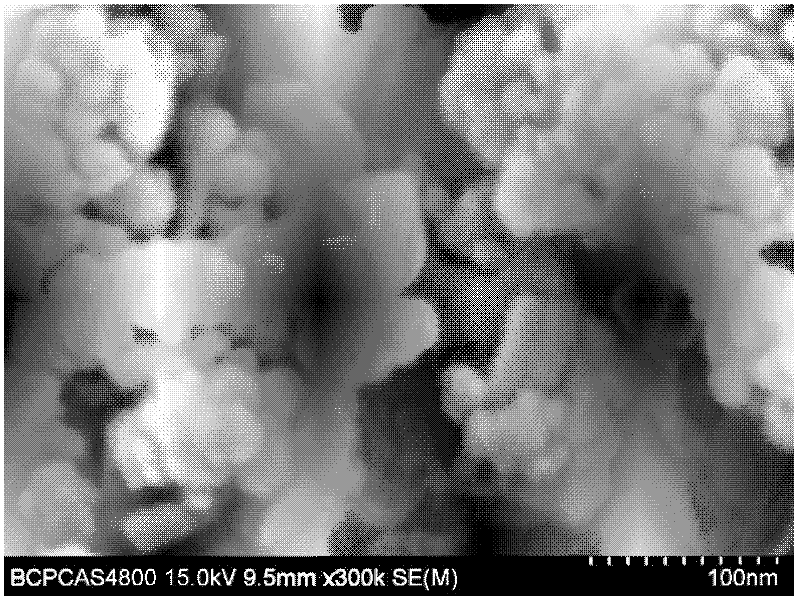

[0029] 1) Preparation of nanoscale lithium iron phosphate primary particles:

[0030] According to the molar ratio of P:Fe:Li=1:1:3, weigh ammonium phosphate, ferrous acetate, and lithium fluoride, dissolve them in water respectively, use magnetic stirring to fully dissolve the raw materials, and then pour the three solutions into the reactor Internal mixing, then use mechanical stirring (rotating speed is 300 rpm) to make the three solutions fully mixed to form a mixed solution; add ethylene glycol to the mixed solution to improve the reaction temperature of the mixed solution, the volume of the ethylene glycol and the mixed solution The volume ratio of the solution is 2: 3, and the pH of the mixed solution is adjusted to be 6.5-8.6. When the temperature of the mixed solution reaches 110-130° C., the reactor is sealed, and nitrogen gas is introduced therein. When a stable precipitate is formed at the bottom of the mixed solution, Separating the precipitate to obtain nanoscale...

Embodiment 2

[0038] 1) Preparation of nanoscale lithium iron phosphate primary particles:

[0039] According to the molar ratio of P:Fe:Li=1:1:3, weigh ammonium dihydrogen phosphate, iron nitrate, and lithium hydroxide, dissolve them in water respectively, use magnetic stirring to fully dissolve the raw materials, and then pour the three solutions into the reaction Mix in the container, then use mechanical stirring (rotating speed is 500 rev / min) to make three kinds of solutions fully mix, form mixed solution; Add ethylene glycol in mixed solution, improve the reaction temperature of mixed solution, the volume of described ethylene glycol The volume ratio to the mixed solution is 2:3, adjust the pH of the mixed solution to 6.8-8.2, when the temperature of the mixed solution reaches 115-125°C, seal the reactor, and then feed nitrogen into it, when the bottom of the mixed solution forms a stable During the precipitation, the precipitate is separated to obtain the primary particle of nano-sca...

Embodiment 3

[0047] 1) Preparation of nanoscale lithium iron phosphate primary particles:

[0048] According to the molar ratio of P:Fe:Li=1:1:3, weigh lithium dihydrogen phosphate, iron hydroxide, and lithium carbonate, dissolve them in water respectively, use magnetic stirring to fully dissolve the raw materials, and then pour the three solutions into the reaction Mix in the container, then use mechanical stirring (rotating speed is 400 rpm) to make the three solutions fully mix to form a mixed solution; add ethylene glycol in the mixed solution to improve the reaction temperature of the mixed solution, the volume of the ethylene glycol is the same as The volume ratio of the mixed solution is 2: 3, and the pH of the adjusted mixed solution is 7.0-7.5. When the temperature of the mixed solution reaches 120° C., the reactor is sealed, and then feeds nitrogen therein. When a stable precipitate is formed at the bottom of the mixed solution, Separating the precipitate to obtain nanoscale lith...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com