Plasma processing apparatus, substrate holding mechanism, and positional deviation detection method

A substrate holding and offset detection technology, applied in the direction of using fluid devices, measuring devices, semiconductor/solid-state device testing/measurement, etc., can solve the problems of inability to detect the positional deviation of semiconductor wafers, inability to detect positional deviation, etc. , to achieve the effect of improving the accuracy of position offset detection and eliminating pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Preferred embodiments of the present invention will be described in detail below with reference to the drawings. In addition, in this specification and drawings, the same code|symbol is attached|subjected to the component which has substantially the same functional structure, and repeated description is abbreviate|omitted.

[0040] (Example of structure of plasma processing apparatus)

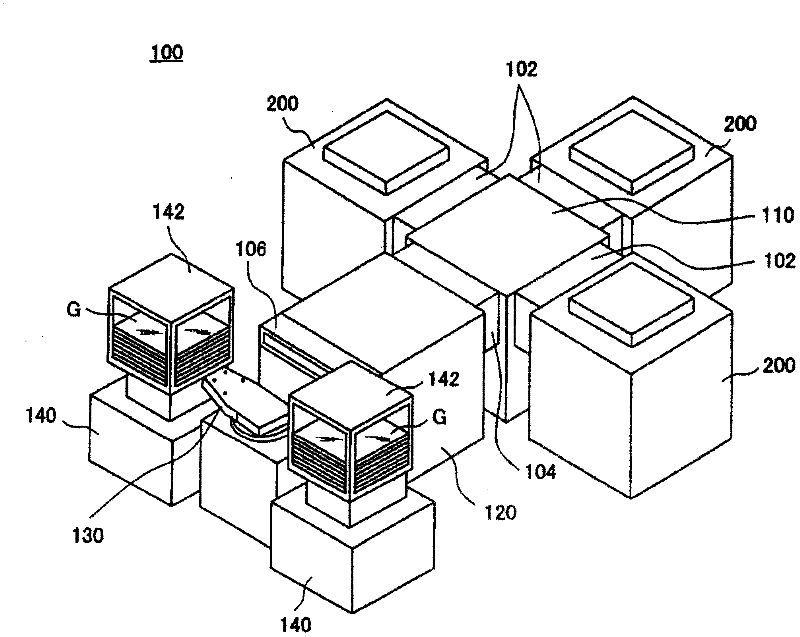

[0041] First, an embodiment in which the present invention is applied to a multi-chamber processing apparatus having a plasma processing apparatus will be described with reference to the drawings. figure 1 It is an external perspective view of the processing apparatus 100 of this embodiment. The processing apparatus 100 shown in this figure has three plasma processing apparatuses for performing plasma processing on the substrate for flat panel display (substrate for FPD) G. Each plasma processing apparatus has a processing chamber 200 .

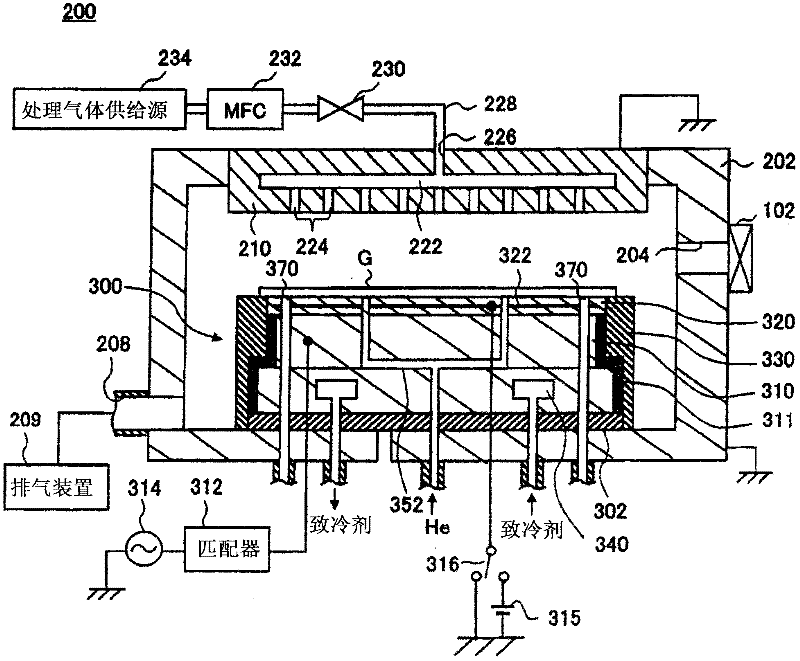

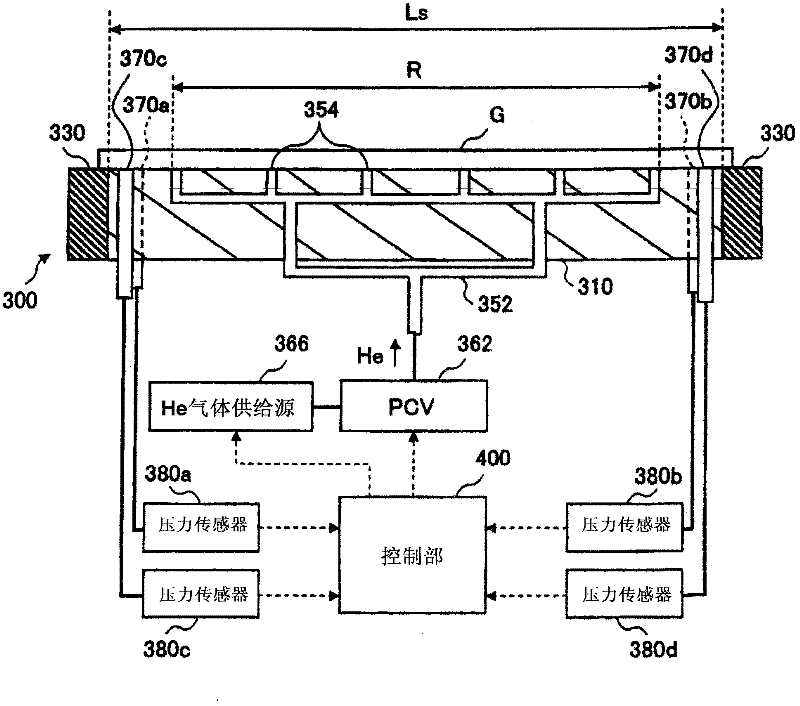

[0042] In the processing chamber 200, for exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com