Ito through-hole integrated capacitive touch screen and manufacturing method

A capacitive touch screen, all-in-one technology, applied in the input/output process of electrical digital data processing, instruments, data processing, etc. problem, to increase the conduction yield, reduce the probability of breakage, and achieve the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be described in further detail below in conjunction with specific embodiments.

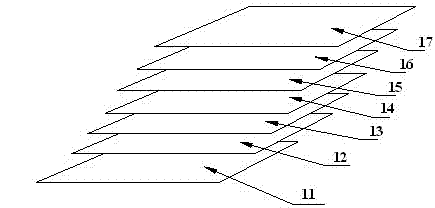

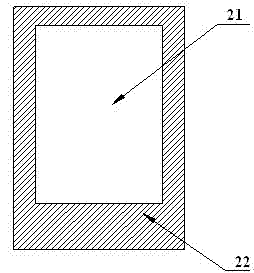

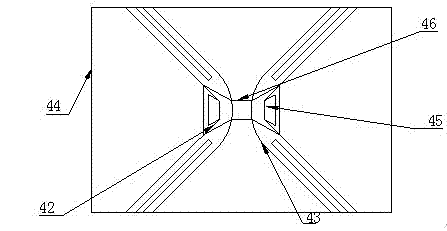

[0058] Such as figure 1 and figure 2 As shown, the ITO through-hole capacitive touch screen includes a chemically strengthened glass substrate 11 with a thickness of 0.5 to 2.0 mm, which is sequentially laminated on a black resin layer 12 of a transparent glass substrate, an ITO electrode 13, a first insulating layer 14, and an ITO through-hole. Aperture electrode 15, metal electrode 16 and second insulating layer 17; Described ITO electrode 13 comprises capacitive screen drive (ITO electrode 1) 42 and induction electrode (ITO electrode 2) 43, has regular figure structure; ITO electrode 1 and ITO The electrodes 2 are on the same level, independent of each other, insulated from each other, and designed vertically. The strengthened glass substrate 11 includes a window area 21 and a non-window area 22 , the black resin layer 12 is distributed in the non-window are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com