A composite insulation block

A composite thermal insulation and building block technology, which is applied in the direction of building materials, etc., can solve the problems of unreasonable formula and proportion, poor thermal insulation performance, and affecting the quality of blocks, so as to increase the thermal insulation effect and thermal insulation performance. Good, the effect of saving building heating and cooling energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

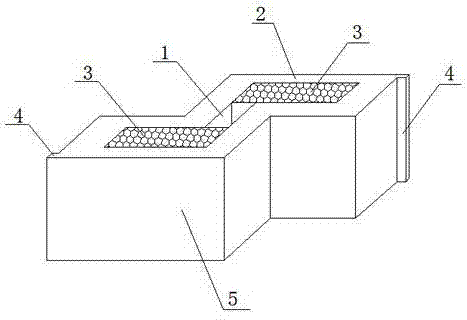

[0028] Embodiment 1, with reference to figure 1 , a composite thermal insulation block, which includes a front block 2 and a rear block 5 formed by partially overlapping the front and rear sides, and the front block 2 and the rear block 5 are square blocks; the front block 2 and the middle part of the back block 5 are provided with a thermal insulation chamber, and the thermal insulation material block 3 is provided in the thermal insulation chamber.

Embodiment 2

[0029] Embodiment 2, in the composite thermal insulation block described in Embodiment 1: a cavity 1 is also provided at the connecting portion of the front block 2 and the rear block 5 .

Embodiment 3

[0030] Embodiment 3, in the composite thermal insulation block described in Embodiment 1: the length of the composite thermal insulation block is 40cm, the width is 20cm, and the height is 19cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com