A kind of production method of thyme essential oil

A production method, technology of thyme, applied in the directions of essential oils/spices, gardening methods, botanical equipment and methods, etc., can solve the problems of low extraction rate of thyme essential oil, long production cycle, unfavorable mass production, etc., to shorten the production cycle, The effect of increasing content, huge economic benefits and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

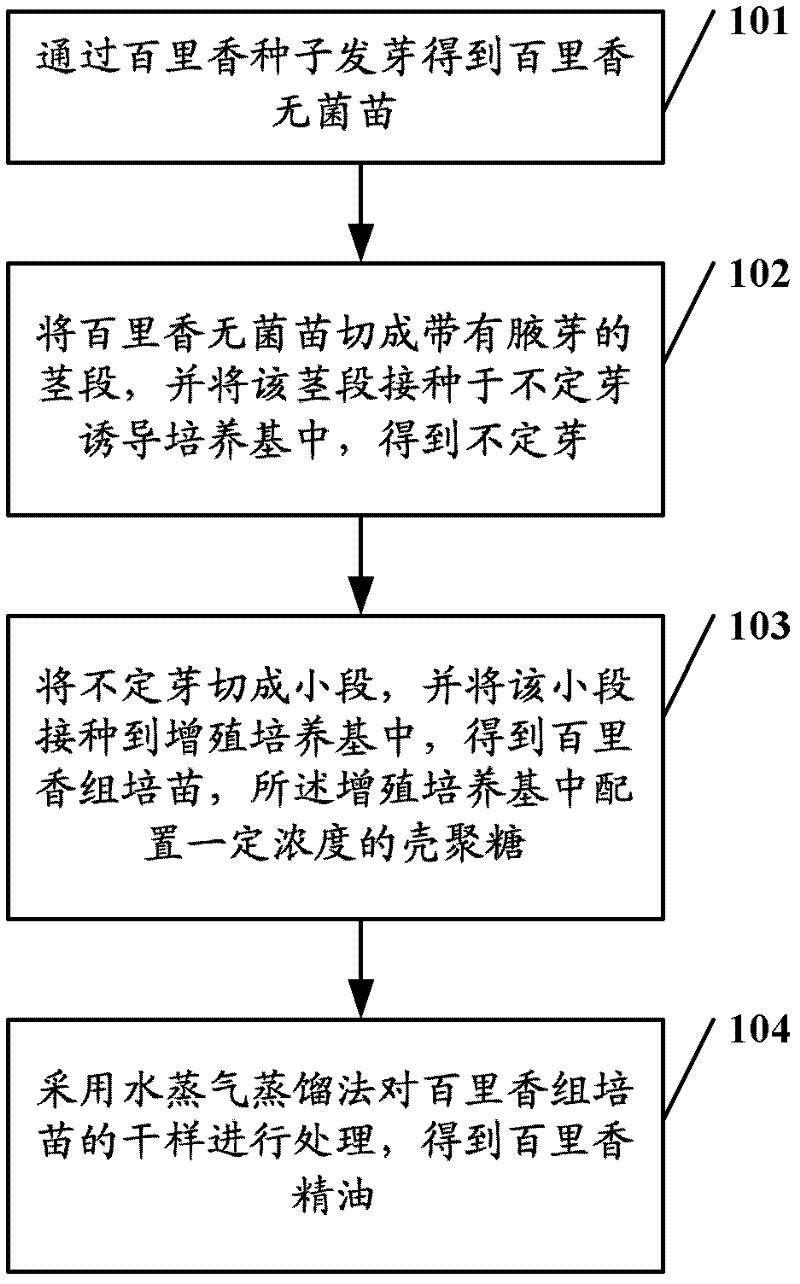

[0016] figure 1 Is the flow chart of the production method of the Thyme essential oil of the embodiment of the present invention, with reference to this figure, the method mainly comprises:

[0017] 101. Obtain thyme aseptic seedlings by germinating thyme seeds, specifically, germinate thyme seeds on 1 / 2MS medium to obtain thyme aseptic seedlings;

[0018] 102. Cut the aseptic thyme seedlings into stems with axillary buds, and inoculate the stems into adventitious bud induction medium to obtain adventitious buds. Specifically, you can choose aseptic seedlings that grow healthy for about 6 weeks , cut it into about 3 cm stem segments with axillary buds, and inoculate the stem segments in the adventitious bud induction medium to induce axillary buds to produce adventitious buds, wherein, the adventitious bud induction medium uses MS as the basic medium,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com