Linear Servo Conveyor System

A conveying system and straight line technology, applied in the field of conveying system, can solve the problems of poor adaptability to the change of press distance, affect the efficiency of punching line, occupy a large space, etc., and achieve the effect of improving adaptability, improving efficiency and increasing conveying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

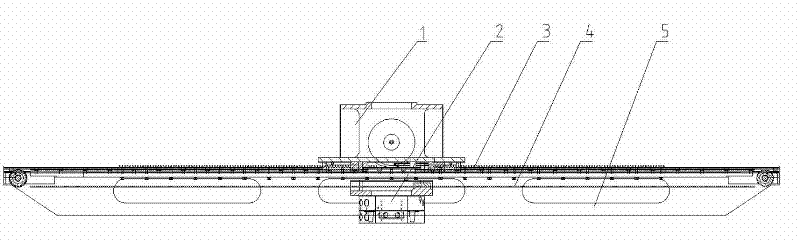

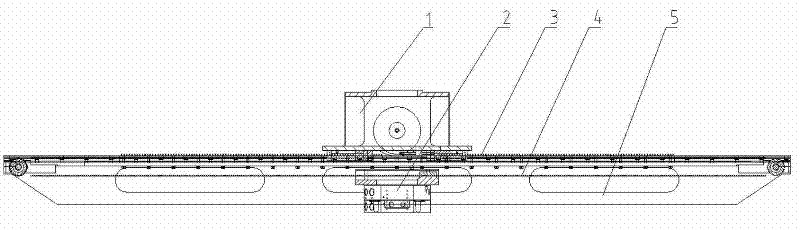

[0019] As a linear servo conveying system, the weight of the linear servo conveying system is particularly critical because it is suspended at the end of the six-axis robot. It must be considered to reduce the weight as much as possible under the premise of ensuring the rigidity of the system; in addition, to reduce the occupied space, it is necessary Quickly move the end picker quick changer 2 while the frame 5 is moving. Therefore, it is necessary to fully consider reducing the weight of the system and increasing the translation speed in the whole system design process.

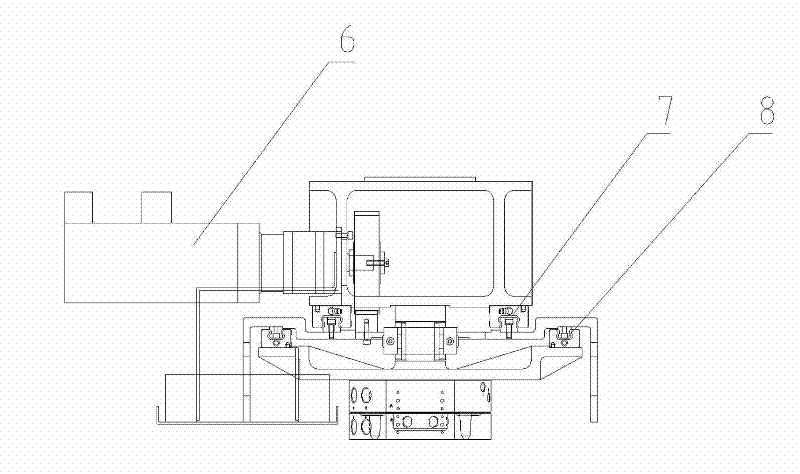

[0020] Such as figure 1 , 2 As shown, the linear servo conveying system of the present invention includes: a mounting support 1 connected to a robot, a servo motor 6 , an end effector quick change device 2 and a frame 5 . The whole system adopts a rectangular structure, the whole system is small and beautiful, and the connection with the six-axis end of the robot is guaranteed by designing different conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com