A usb iron shell mold

A mold and iron shell technology, applied in the field of USB iron shell molds, can solve the problems of easy popping, large plugging force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below, the present invention will be further described in conjunction with the accompanying drawings.

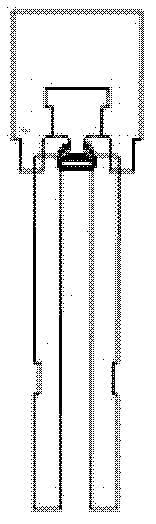

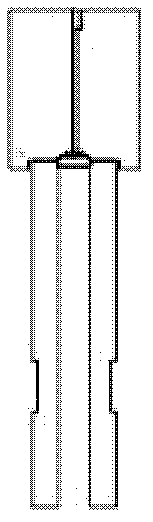

[0027] A USB iron shell mold, the USB iron shell mold includes an upper mold and a lower mold facing the upper mold, and the USB iron shell mold includes a first station for adjustment and a second station for forming station and a third station for riveting points, the first station, the second station and the third station are arranged in sequence between the upper die and the lower die.

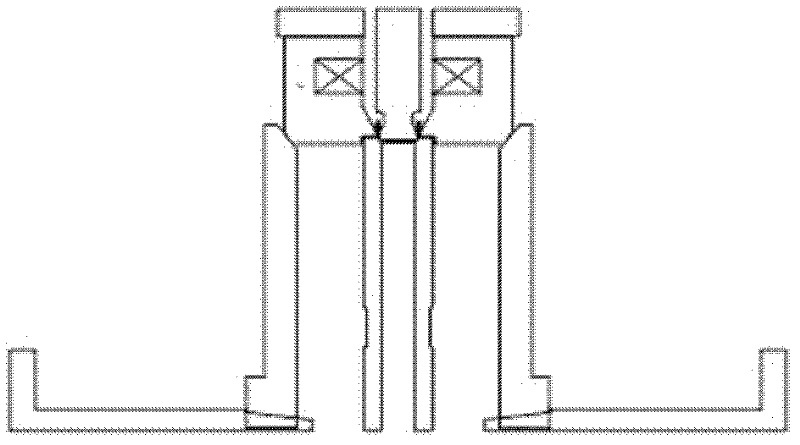

[0028] Please refer to figure 1 , figure 1 It is a schematic diagram of the first station for adjustment of the USB iron shell mold of the present invention. Further, the first station includes a first upper stamping block and a first lower stamping block, the first upper stamping block is connected to the upper mold, and the first lower stamping block is connected to the lower mold.

[0029] Further, both sides of the first upper stamping block are provided with adjustment blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com