Water washing and separation method of copper powder and shaker with controllable water flow

A separation method and water flow technology, applied in the field of washing shakers, can solve the problems of low sorting operation efficiency of washing shakers, limiting copper metal recovery technology, affecting production efficiency, etc. Choose the effect of operation efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

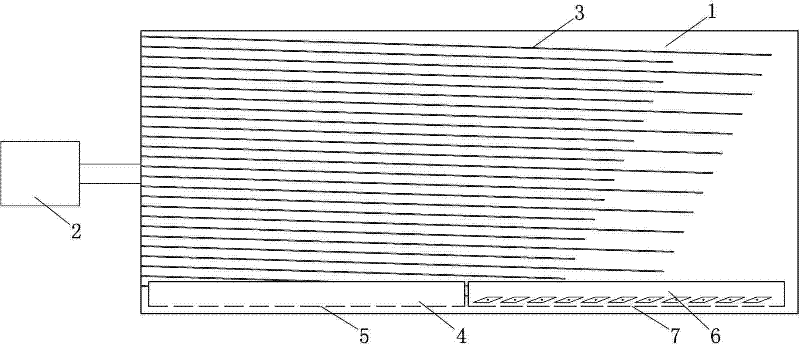

Image

Examples

Embodiment

[0022] Example 1. The washing separation method of copper powder adopts the following process steps:

[0023] (1) Screen the mixture of non-metallic powder and copper powder obtained after crushing through an automatic vibrating sieve to obtain qualified mixture particles;

[0024] (2) The qualified mixture particles obtained by screening are pumped by an electric pump to a shaker distribution device, and the materials are divided and evenly distributed to three shaker feeding troughs with controllable water flow;

[0025] (3) The mixture formed by mixing with water in the feeding tank flows from the outlet of the feeding tank to the bed surface of the shaker body. Under the action of the shaker drive device, the shaker shakes back and forth, and the non-metallic powder and copper powder separation;

[0026] (4) When the water volume of the shaker is small and the fluidity of the mixture is poor, and it is necessary to add water, add water to the water tank, and the water f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com