Novel process for preparing natural solid soy sauce

A production process and technology of soy sauce, which is applied in the field of solid-state natural fermented soy sauce with dephenolized cotton protein and bran drum, can solve the problems of cottonseed amino acid loss, excessive protein denaturation, danger, etc., to overcome poor flavor, outstanding technical advantages, overcome The effect of long production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in combination with specific embodiments.

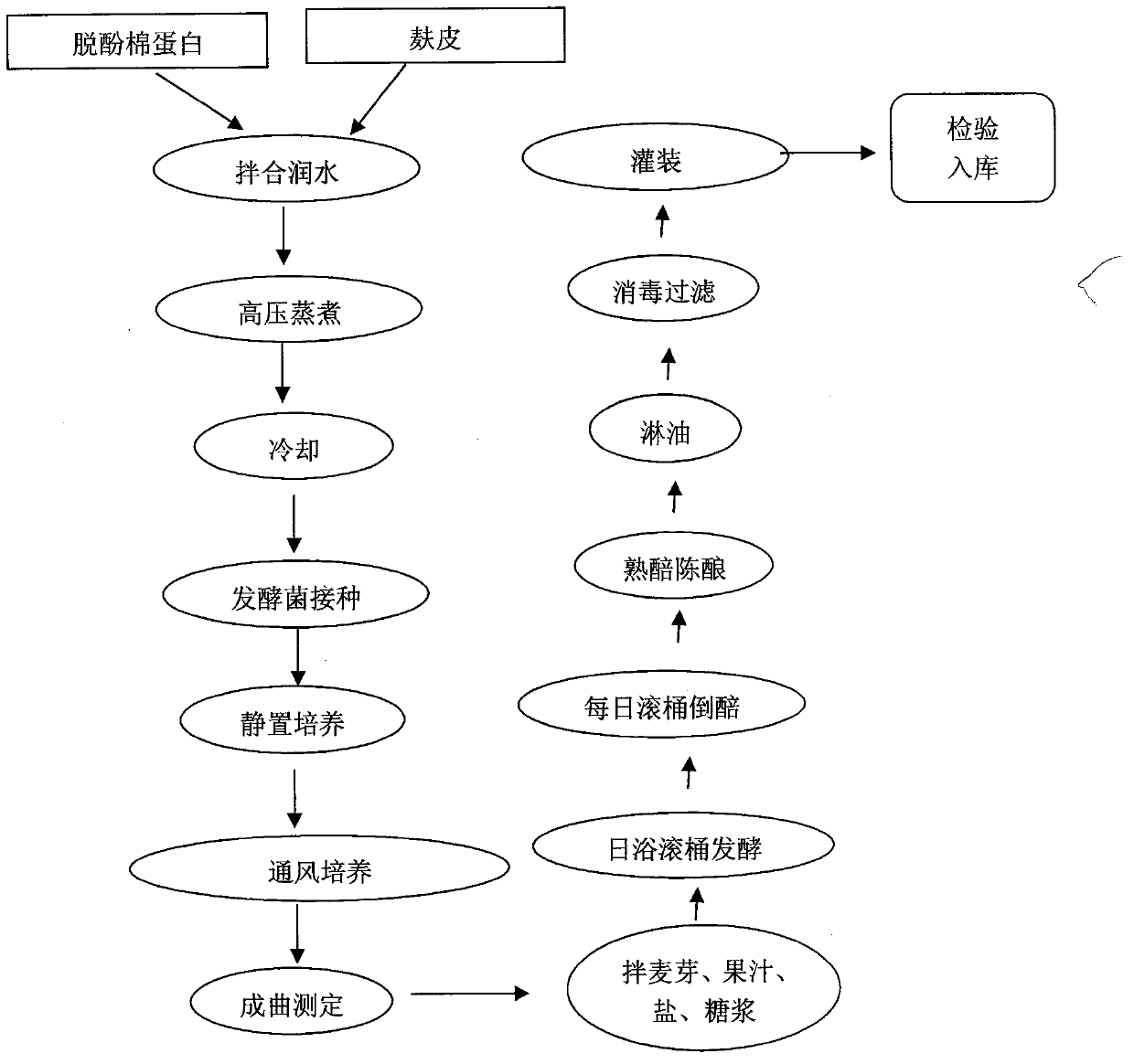

[0015] With dephenolized cotton protein as the main raw material, the dephenolized cotton protein and bran are mixed and moistened, steamed under high pressure, fermented bacteria are inoculated and cultured, the cooked grains are aged, oiled, sterilized and filtered, and then filled into the warehouse.

[0016] Specifically, the dephenolized cotton protein and bran are batched in a weight ratio of 1:1, mixed and moistened, steamed under high pressure, and the total water content after cooling is not less than 65%, fermented bacteria are inoculated, cultured for 24 hours, ventilated Cultivation, after the determination of the finished koji reaches the standard, it is mixed with malt, fruit juice, salt, and syrup for seasoning, fermented in a daily bathing barrel, and further fermented in a daily barrel, aging the mature fermented grains, pouring oil, and then sterilized and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com