Two-Stage Brightness Converter

A converter and brightness technology, used in lasers, phonon exciters, laser components, etc., can solve problems such as failure and absence of isolators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

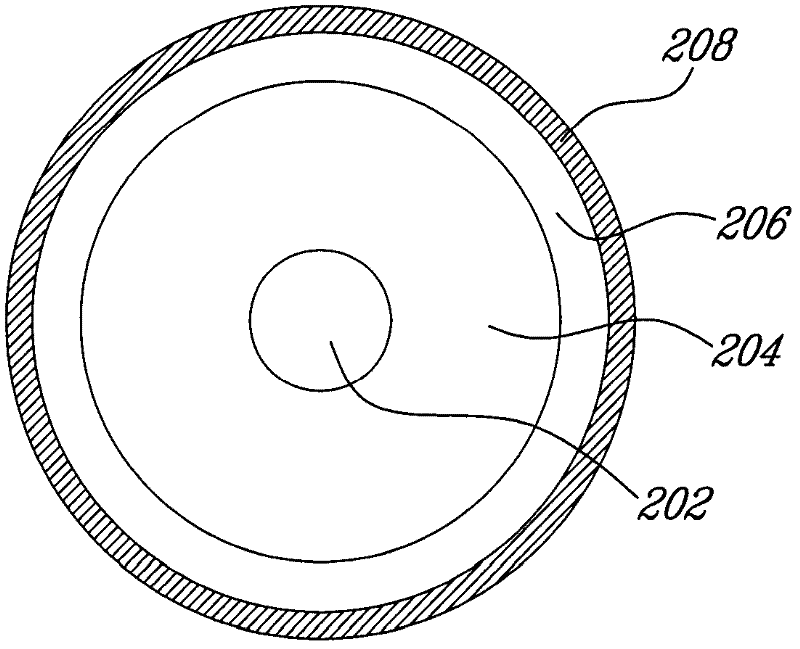

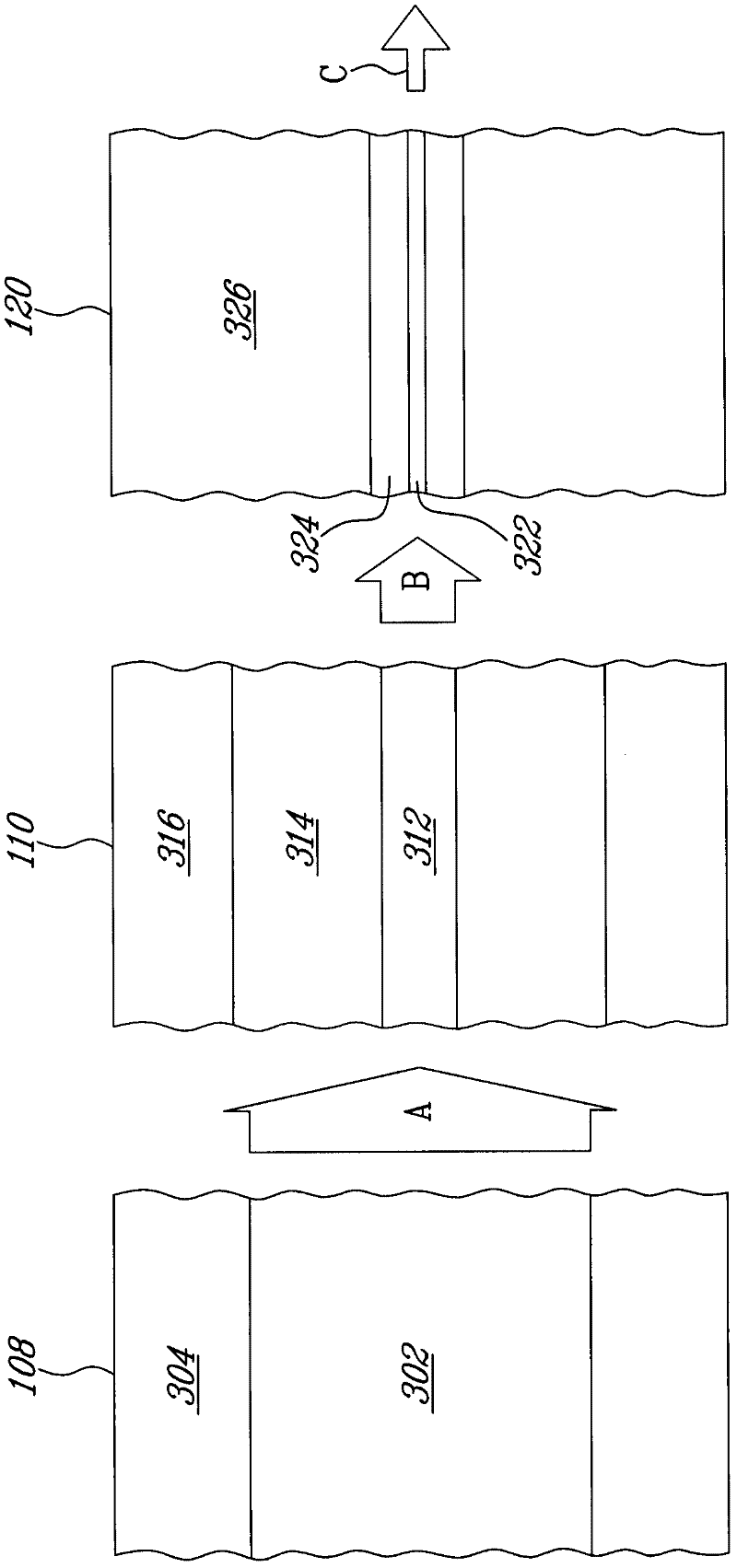

[0061] now give the basis figure 1 An example of a specific design of a two-stage brightness converter. It should be understood that the parameters of the converter specified below are given by way of example only, and that there are many other possible designs for such a two-stage luminance converter.

[0062] The first stage 102 of the brightness converter should be carefully designed to obtain lasing emission in the second optical wavelength band (ie between 1020 and 1030 nm). The first stage 102 should be designed to have a maximum gain spectral density in the second optical band for efficient lasing.

[0063] With strong population inversion within the DCOF 102 of the first stage 102, such efficient lasing in the second optical wavelength band (ie between 1020 and 1030 nm) is obtained. In order to obtain the desired strong population inversion, a short cavity and a large ratio of core diameter to inner cladding diameter are used in order to obtain a strong absorption of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com