Large-power 1064 nm near-infrared laser based on wattle structure

A slab structure, high-power technology, applied in the direction of lasers, laser components, phonon exciters, etc., can solve the problems of short absorption length, complex structure design, and limited development, so as to increase power density, improve beam quality, Eliminates the effect of thermal focus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

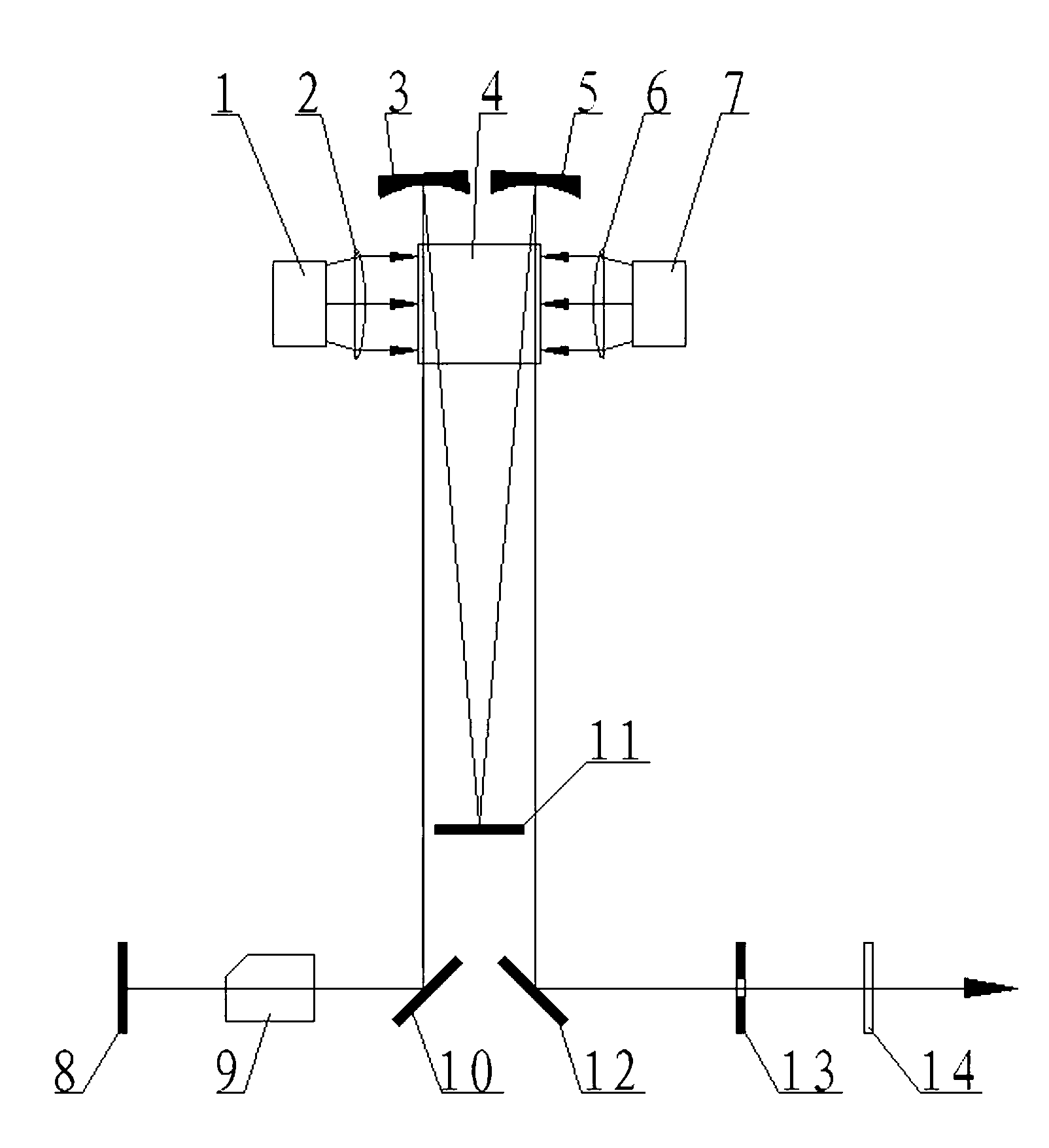

[0019] refer to figure 1 , the high-power 1064nm near-infrared laser based on the slab structure of the present invention includes: a laser crystal 4, semiconductor laser pumping modules 1, 7 separated on both sides of the laser crystal 4, arranged between the laser crystal 4 and the semiconductor laser pumping modules 1, 7 The lens 2, 6 between them, the lens 2, 6 forms a lens group, and the laser resonator that forms the pump light emitted by the semiconductor laser pump module 1, 7 into a 1064nm laser with high beam quality, and also includes: the above-mentioned high The beam quality of the 1064nm laser is modulated by the modulation device 9 .

[0020] The laser resonator will be described in detail below.

[0021] refer to figure 1 , the laser resonator is composed of cavity mirrors, specifically cylindrical mirrors 3, 5 and plan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com