Polarization-maintaining fiber pumping combiner and manufacturing device and method thereof

A polarization-maintaining optical fiber and beam combiner technology, which is applied in the direction of polarization optical fiber, laser, cladding optical fiber, etc., can solve the problems of easy damage of stress holes and environmental pollution, and achieve the effects of environmental protection, convenient processing, and high pump power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to solve the problems that the existing technology cannot realize the large-scale polarization-maintaining optical fiber pumping beam combiner, the stress hole is easily damaged, and the environment is polluted during processing, a new type of polarization-maintaining pumping beam combiner and its production equipment are proposed. Manufacturing method.

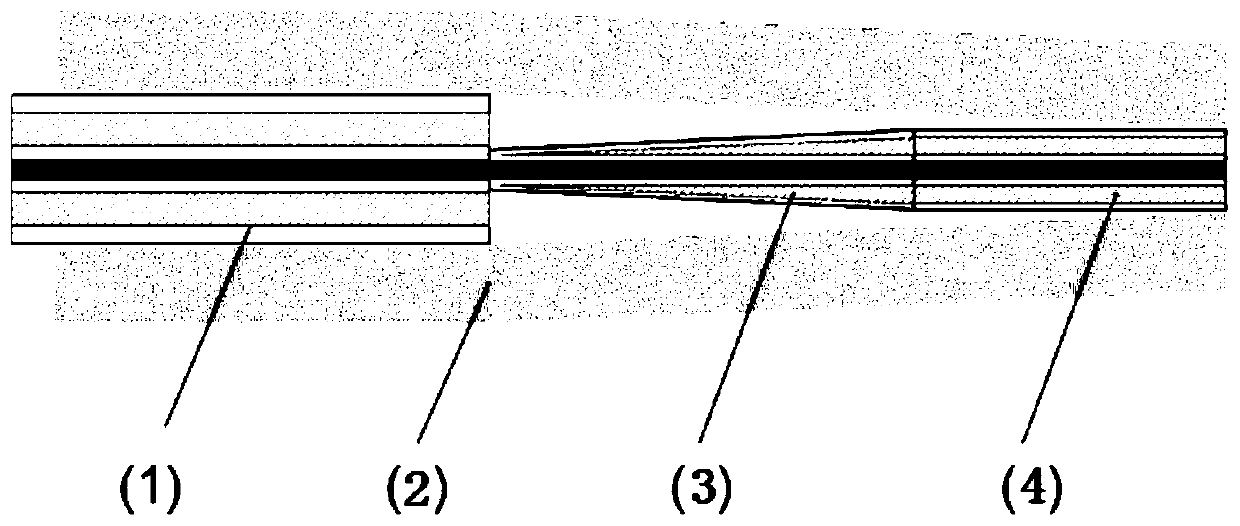

[0032] A high-power polarization-maintaining pump fiber combiner according to the present invention has a structure such as figure 2 As shown, it includes a polarization maintaining fiber 1, a pumping fiber 2, a mode matching section 3, and a polarization maintaining fiber adapter fiber 4 as signal input channels. The core diameter of the polarization maintaining fiber adapter fiber 4 is slightly larger than that used as a signal input channel. The core diameter of the polarization-maintaining fiber 1 of the input channel, the mode-matching section 3 is a tapered part produced by heating and diffusing the cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com