Wire rod, steel wire and method for manufacturing wire rod

A manufacturing method and wire rod technology, applied in the field of steel wire, can solve problems such as increased manufacturing costs, and achieve the effects of low yield, excellent wire drawing performance, and good yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0045] (Constitution of wire rod)

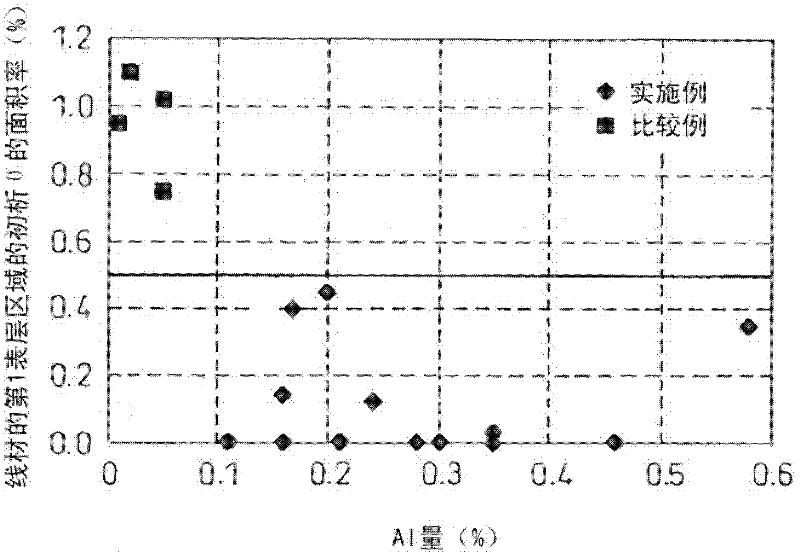

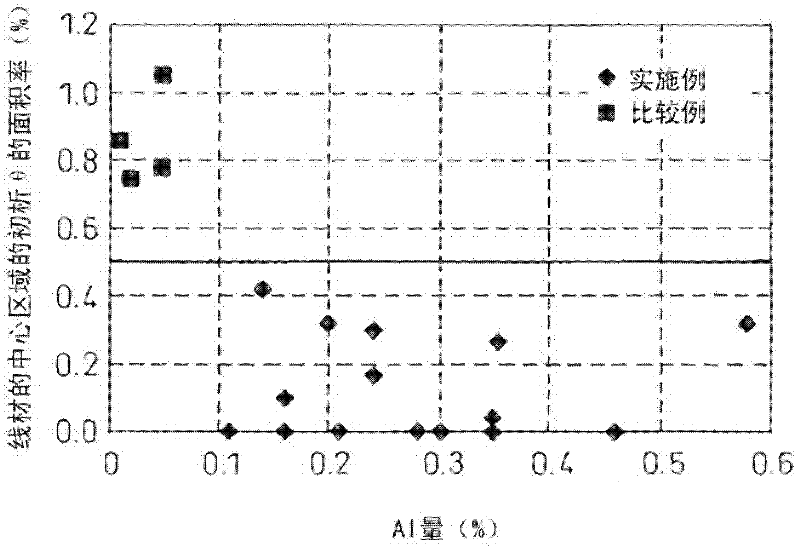

[0046] In the first embodiment of the present invention, the area of 0.5% or less of the central region of the cross section perpendicular to the longitudinal direction of the wire rod and the area of 0.5% or less of the surface layer region (first surface layer region) of the cross section are pro-eutectoid cementite Tissue occupies the wire.

[0047] According to the investigation of the inventors of the present invention, the proeutectoid cementite ratio in the surface layer region of the wire rod and the central region of the wire rod before wire drawing is related to the ductility of the steel wire after wire drawing, and the area ratio of cementite in the surface layer region of the wire rod can be suppressed to When it is 0.5% or less, the delamination resistance of the steel wire obtained by wire drawing is improved, and by suppressing the area ratio of cementite in the central region of the wire rod to 0.5% or less, wire-drawing...

no. 2 Embodiment approach

[0102] (Constitution of steel wire)

[0103] The second embodiment of the present invention is a steel wire having a tensile strength of 1800 MPa or more obtained by cold drawing the wire rod of the first embodiment with an actual deformation of 1.3 or more. The area of 0.5% or less of the surface layer region (second surface layer region) of the cross section perpendicular to the longitudinal direction of the steel wire is occupied by proeutectoid cementite.

[0104] Here, the second surface layer region refers to a region from the steel wire surface layer (edge portion in cross section) to the inside of 20 μm.

[0105] The steel wire thus obtained may also be subjected to steel bluing treatment, hot-dip galvanizing, hot-dip aluminum-zinc alloy plating, and the like as a final treatment.

Embodiment

[0107] Hereinafter, the present invention will be described in more detail by way of examples, but of course the present invention is not limited to the following examples. Of course, it can be implemented with appropriate modifications within the scope suitable for the gist of the present invention, and these modes are included in the scope of the present invention. within the technical scope.

[0108] Table 1 and Table 2 show the chemical components of A steel to V steel used in Examples 1 to 15 and Comparative Examples 1 to 19 of the present invention. In addition, in Tables 1 to 6, the numerical values or unfavorable results that do not fall within the above-mentioned predetermined range are underlined.

[0109] After heating the steel slab containing the chemical components shown in Tables 1 and 2, it was processed into a wire rod having a diameter of 7 to 18 mm by hot rolling, and after being coiled at a predetermined temperature, a steel wire toughening treatment was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com