Microphone

A microphone and shell technology, applied in the field of microphones, can solve problems such as the limitation of product electrical performance requirements, the limited volume of the back cavity of the microphone, and the limiting sensitivity of the microphone.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

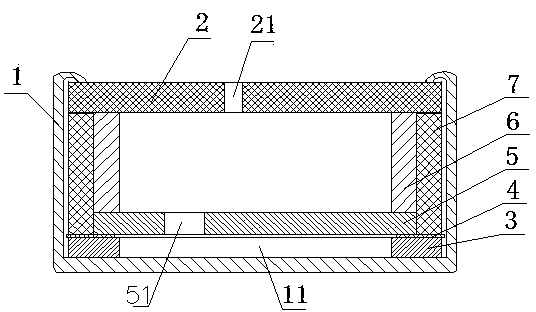

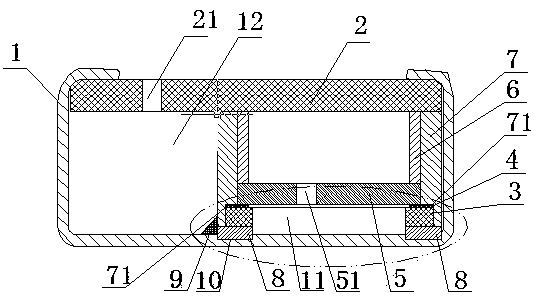

[0032] figure 2 It is a cross-sectional view of a columnar metal support column structure in an embodiment of the present invention; image 3 yes figure 2 Partial enlarged view of Figure 4 It is a schematic cross-sectional structure diagram of Embodiment 1 of the present invention; Figure 5 It is a top view of a columnar metal support column according to an embodiment of the present invention; Image 6 It is a top view of an insulating cavity according to an embodiment of the present invention; Figure 7 It is a cross-sectional view of an "L"-shaped support platform structure in Embodiment 1 of the present invention; Figure 8 yes Figure 7 Partial enlarged view of Figure 9 It is a top view of an "L"-shaped support platform according to an embodiment of the present invention. Such as Figure 2-9 As shown, a microphone includes an external packaging structure composed of a housing 1 and a circuit board 2, and the inside of the packaging structure is provided with a...

Embodiment 2

[0043] Figure 10 It is a cross-sectional view of the structure form of the second columnar metal support column in the embodiment of the present invention; Figure 11 It is a cross-sectional view of the structure of the "L"-shaped support platform in Embodiment 2 of the present invention. Such as Figure 10 , Figure 11As shown, the difference between the present embodiment and the first embodiment is that the sound hole 21 is arranged on the circuit board 2 in the surrounding area of the metal ring 6, so that the first cavity 11 and the second cavity 12 are communicated. Forms the back cavity of the microphone. The microphone with this structure makes the volume of the rear cavity larger, which makes it easier to improve the ultimate sensitivity of the product and achieve the electrical performance required by the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com