Moving iron loudspeaker diaphragm with small front cavity

A horn membrane and front cavity technology, which is applied to the fixing/tightening of the diaphragm, the frequency/directional characteristic device, and the sensor, etc., can solve the problems of insufficient bandwidth and difficult process of the moving iron horn, and achieve the reduction of the composite diaphragm. area, increasing the volume of the back cavity, and the effect of good bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

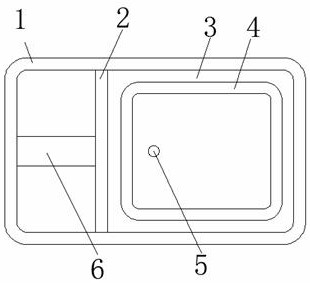

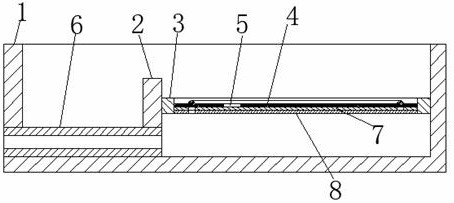

[0027] refer to Figure 1 to Figure 2 , a moving iron horn diaphragm with a small front cavity provided by the present invention: includes a casing 1, the casing 1 is composed of a front casing, a rear casing, a left casing, a right casing and a bottom casing, and the opposite side of the left casing and the right casing The distance between them is the length of the shell 1; the partition 2 is set on the inner wall of the shell 1, and the partition 2 is fixedly connected between the front shell, the rear shell and the bottom shell; it is set inside the shell 1 for frequency shifting for the formant The connecting pipe 6 for tuning, the connecting pipe 6 is fixedly connected to the upper wall of the bottom shell, and the outer walls at both ends of the connecting pipe 6 respectively penetrate the left shell of the shell 1 and the partition 2; the bracket 3 arranged inside the shell 1 is fixedly connected to the Between the partition 2 and the right shell, the inner wall of the...

Embodiment 2

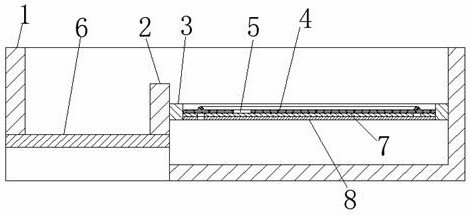

[0031] refer to image 3 , a moving iron horn diaphragm with a small front cavity provided by the present invention: the connecting pipe 6 is installed in a semicircular tube, and the center of the circle is on the same plane as the lower wall of the bottom case, thus a double moving iron unit can be derived, and each unit is semicircular The tubes are relatively composed of a whole tube, and more tuning methods have been obtained.

[0032] Working principle: The composite diaphragm vibrates through the drive part inside the moving iron unit to generate sound. By setting the partition 2 inside the shell 1, the volume of the front cavity is smaller, and the area of the composite diaphragm is reduced, so that more sound can be obtained. Good bandwidth, while increasing the volume of the back cavity, so that higher sound pressure can be obtained. The performance of the product can be adjusted by replacing the connecting tube 6 with different inner diameters, different materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com