Loudspeaker box and its assembly process

A loudspeaker box, sound guide technology, applied in the direction of sensor, single transducer combination, transducer shell/cabinet/stand, etc. Enhanced sound effect, increased volume, simple and efficient assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below with reference to the accompanying drawings and embodiments.

[0026] The speaker box of the present invention can be applied to portable mobile communication devices, such as mobile phones, game consoles and other electronic products.

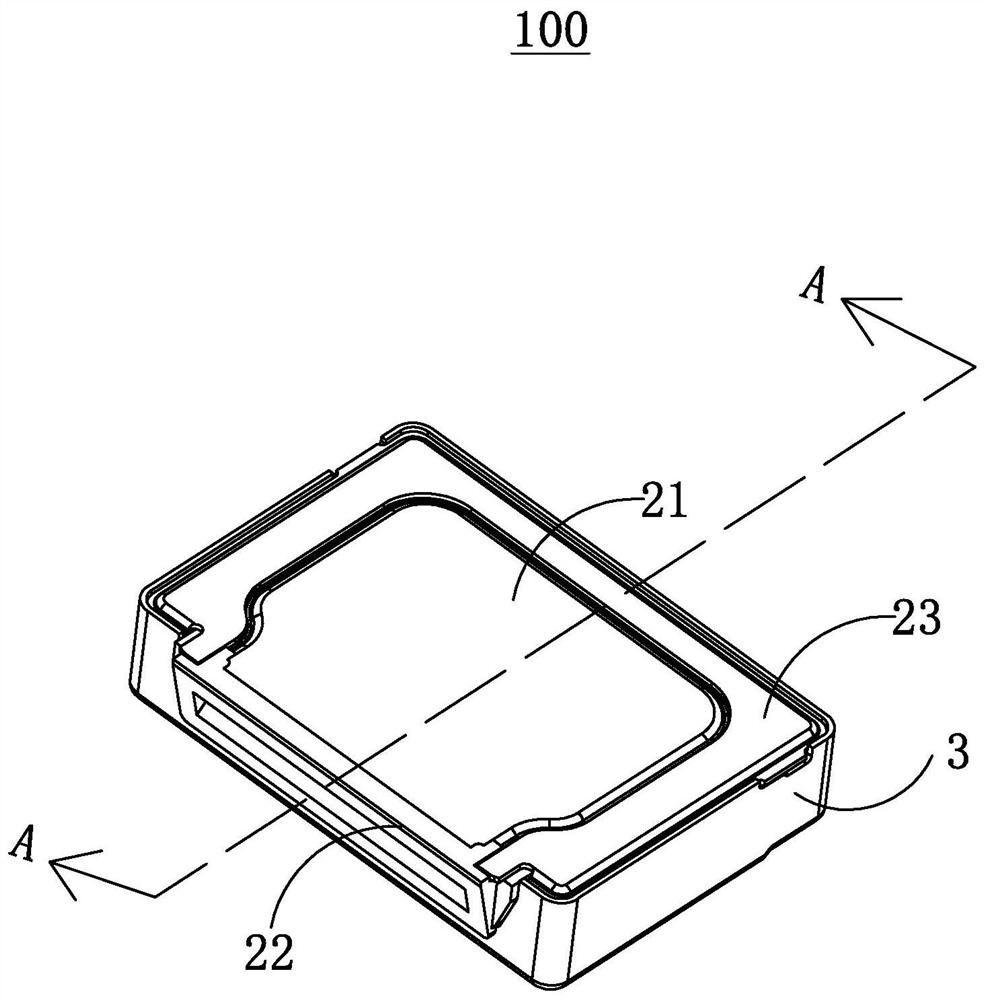

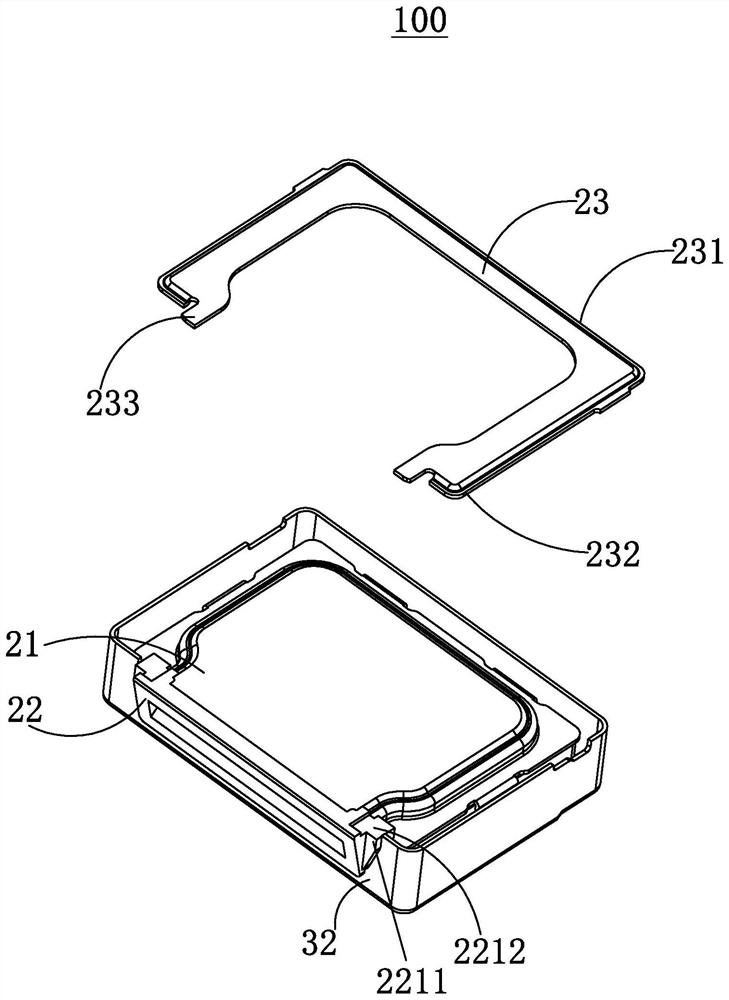

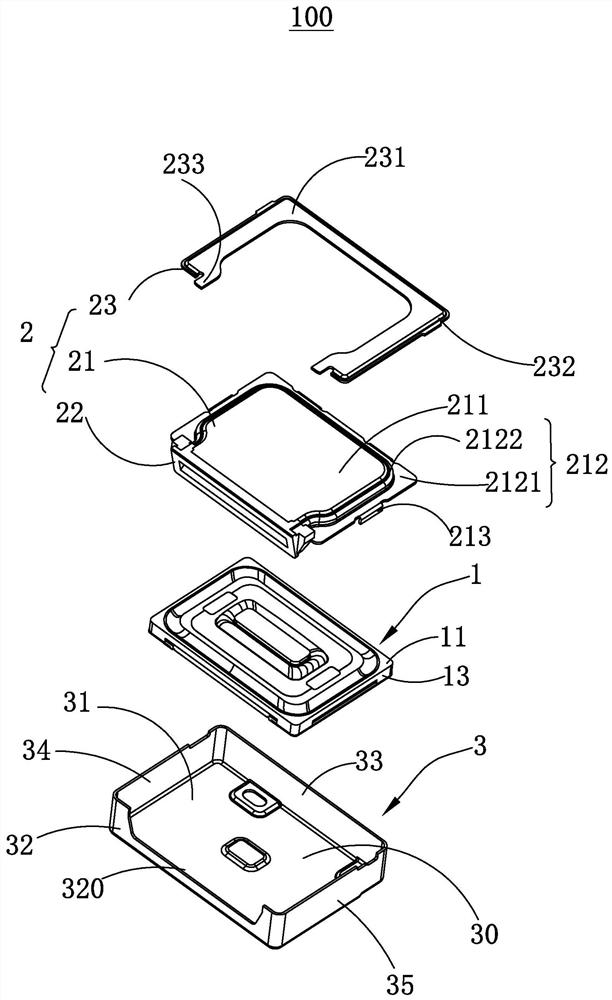

[0027] like Figure 1 to Figure 5 As shown, the speaker box 100 of the present invention includes a sound-generating unit 1 and a casing for accommodating the sound-generating unit 1 . The casing includes a front cover 2 and a rear cover 3 which is covered with the front cover 2 .

[0028] The sound-generating unit 1 includes a vibration system, a magnetic circuit system and a basin frame 13 . The vibration system can vibrate in the vibration direction. In this embodiment, the vibration system includes a diaphragm 11 , and the magnetic circuit system includes a yoke 12 .

[0029] like figure 2 and 3 As shown, the front cover 2 includes a support member 21 for supporting the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com