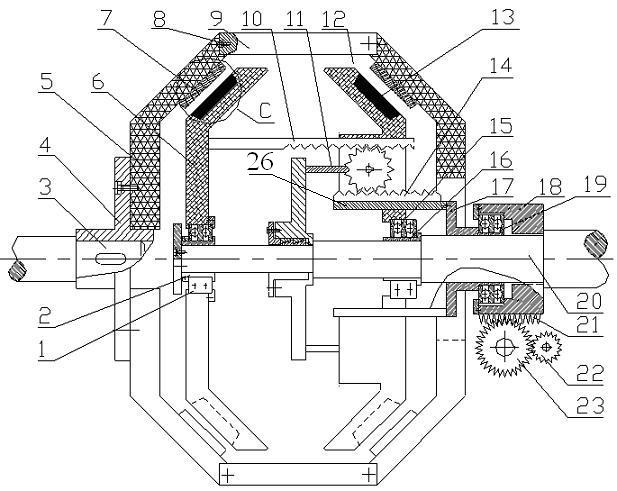

A Wedge Disc Adjustable Speed Magnetic Coupling

A magnetic coupling and wedge-shaped technology, which is applied in the direction of electrical components, electromechanical devices, electromechanical transmission devices, etc., can solve the problems of motor heating and failure, and achieve the effects of prolonging service life, small error transmission, and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

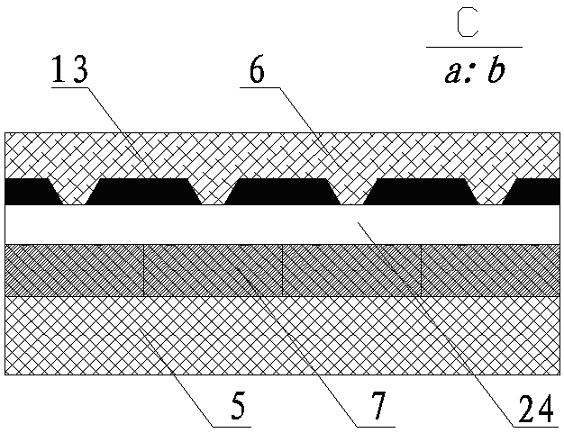

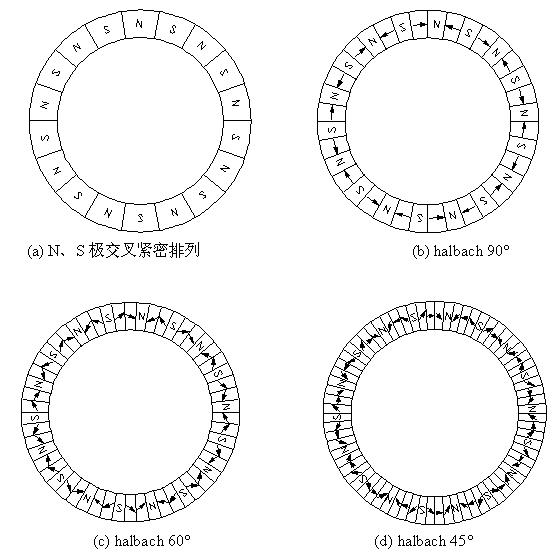

Method used

Image

Examples

Embodiment 2

[0038] Embodiment 2: On the basis of Embodiment 1, the mechanism that causes the square bearing base 18 to generate axial displacement can be replaced with one of the crank slider mechanism or the threaded screw mechanism; wherein Figure 5 A schematic diagram of the movement of the slider crank mechanism is given. The rotation angle of the crank 25 is precisely controlled by a stepping motor, so that the crank converts the rotating pair into a moving pair through two connecting rod members, so that the square bearing base 18 will also be affected by the sliding block. The horizontal force acting on it produces a horizontal displacement, which achieves the purpose of providing a power source.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com