Round terminal and method of making the same

A terminal and round bar technology, which is applied in the field of round terminal and its processing, can solve the problems of increasing the cost of gold plating, large loss of plating, and increased plating area, and achieve the effect of reducing the cost of plating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

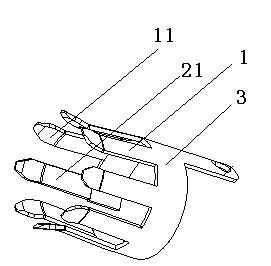

[0016] The present invention provides a round terminal, such as figure 1 As shown, it includes a roll of round bar 3, on which bar 3 extends perpendicularly to bar 3 and is evenly distributed with splicing strips 1, and the end 11 of said splicing strip 1 is turned outwards, and said splicing strip 1 One and only one side is coated with plating.

[0017] A method for making a round terminal, such as Figure 5 shown, including the following steps,

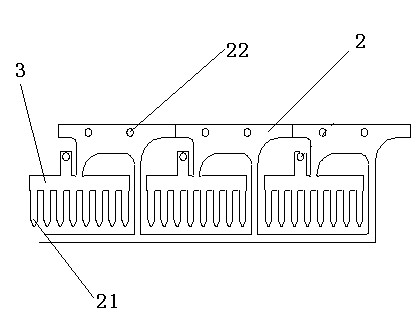

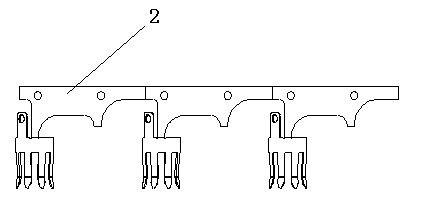

[0018] Step 1: Stamping, that is, the first forming, the plate is stamped into a profile plate of the terminal forming strip through a stamping die that already has a terminal forming template, such as figure 2 shown.

[0019] Step 2: Electroplating, electroplating the profiled plate-shaped terminals produced in step 1 through the electroplating production line, setting the speed and current of the brush plating machine according to different coating thicknesses, reducing the moving speed of the terminal plate, increasing The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com