LED surface light source and manufacturing method thereof

A technology of LED surface light source and LED chip, which is applied in the light source, electric light source, point light source, etc., can solve the problems of large stress on the substrate chip, shortened life of the LED chip, and local temperature rise, so as to reduce the probability of failure. , The effect of reducing welding points and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

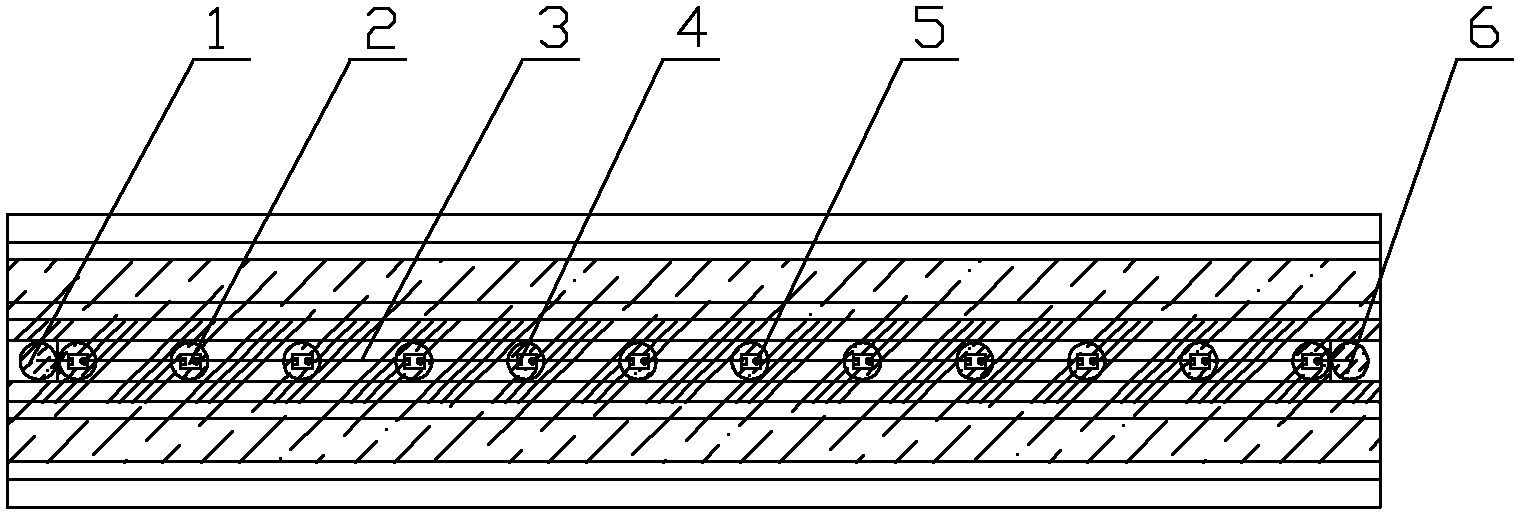

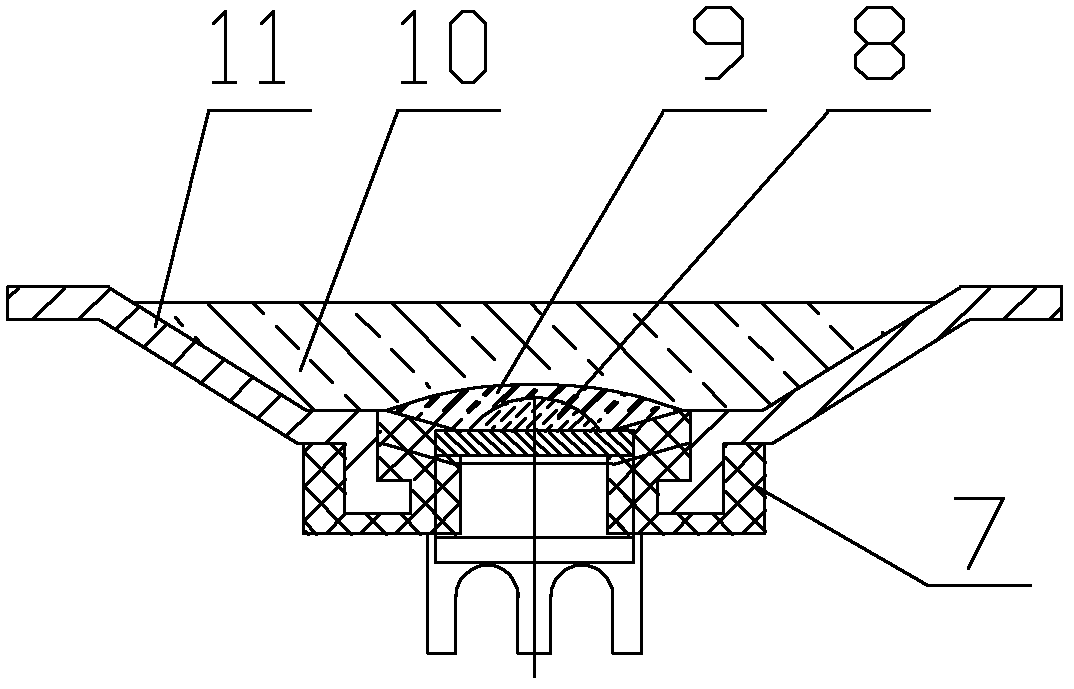

[0032] Such as Figure 1 to Figure 3 As shown, Embodiment 1 of the present invention is an LED surface light source. The surface light source includes a first power supply external lead electrode 1 and a second power supply external lead electrode 6 for supplying power to the entire light source, LED chips 2 of strip-shaped cloth, strips The chip connecting wire 3 of the strip-shaped cloth sheet, the LED chip positive electrode pad 4 of the strip-shaped cloth sheet, the LED chip negative electrode pad 5 of the strip-shaped cloth sheet, the positive electrode pad 4 and the negative electrode pad 5 of the adjacent chip 2 are connected by the connecting wire 3 connected together to form a connected circuit. another example figure 2 As shown, the spherical rubber block 8 in the first adhesive layer covers the single chip 2 and the positive and negative electrode pads; the segmented spherical rubber block 8 is covered with a continuous colloid lens layer 9, that is, the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com