Transformer for output of high-voltage high-power converter

A transformer and high-power technology, which is applied in the field of transformers output by high-voltage and high-power converters and their impact strength testing, can solve the problems that transformers are not suitable for transformers, cannot meet requirements, and cannot be satisfied, so as to reduce eddy current loss and miscellaneous Dissipation loss, enhance reliability, reduce the effect of load loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

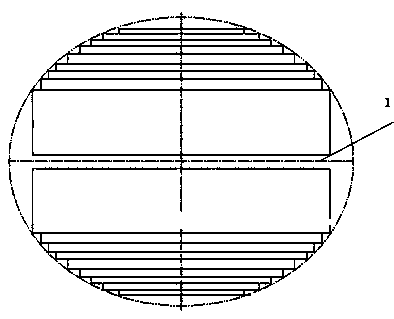

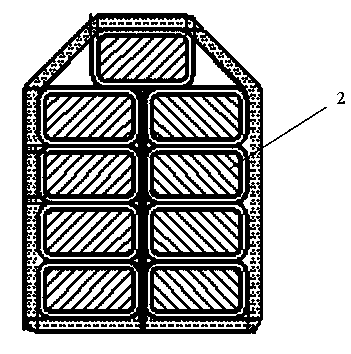

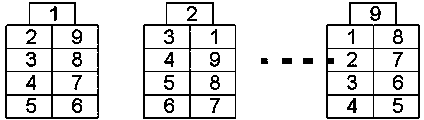

[0027] The invention discloses a transformer used for the output of a high-voltage high-power converter. Based on the impedance characteristics of the output transformer, the symmetry of the low-voltage winding and the output linearity, the structure of the low-voltage winding is determined. Insulation structure and lifespan that meet the output requirements in the range of 0~300Hz. It meets the requirements of the high du / dt working condition of the primary side of the access transformer, and at the same time considers the influence of the pulse width modulation output of the converter on the transformer. In order to meet the temperature rise standard requirements of the output transformer under specific working conditions, the main materials of the core and winding are selected. Reduce the noise of the output transformer in the range o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com